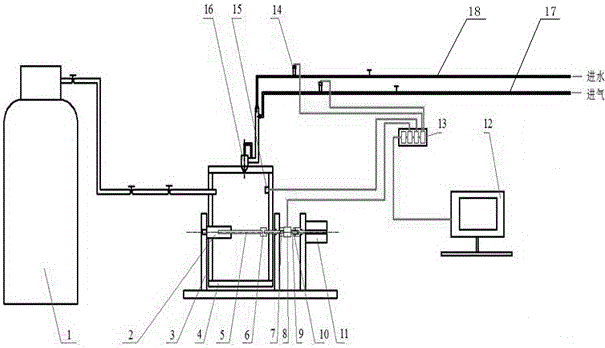

Experimental device and measurement method of rotating cylinder icing and ice adhesion measurement

An experimental device and adhesion technology, applied in the field of aircraft safety, can solve problems such as expensive costs, large manpower and material resources, and achieve the effect of easy disassembly and transportation, avoiding excessive waste, and achieving maximum utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The size of the selected cylindrical test piece is: length 160mm, diameter 10mm. The material of the experimental piece is aluminum.

[0047] The set freezing temperature is -15°C, the pressure of the air delivery pipeline is 0.2MPa, and the pressure of the pure water delivery pipeline is 0.1MPa. According to the actual performance specification of the nozzle, the corresponding liquid water droplet diameter is 20μm (such as Image 6 As shown, after the nozzle design is finalized, the manufacturer will conduct a series of calibration experiments to determine the diameter of water droplets under different water pressure and air pressure conditions. Therefore, the manufacturer will provide an instruction to determine the size of the droplet diameter according to their manufacturer's curve). Set the freezing time to 8-10 minutes. The freezing time after freezing is 4-6 minutes.

[0048] The measurement steps are as follows:

[0049] 1) Debug and inspect the correspondin...

Embodiment 2

[0059] The size of the selected cylindrical test piece is: length 160mm, diameter 10mm. The material of the experimental piece is stainless steel.

[0060] The set freezing temperature is -30°C, the pressure of the air delivery pipeline is 0.3MPa, and the pressure of the pure water delivery pipeline is 0.25MPa. According to the actual performance specification of the nozzle, the corresponding liquid water droplet diameter is 30μm. Set the freezing time to 9 minutes. The freezing time after freezing is 5 minutes.

[0061] The measurement steps are as follows:

[0062] 1) Debug and inspect the corresponding parts of the whole device: reliability detection of the adjustment switch in the device, operation test of the KingView monitoring program, reliability detection of the data acquisition module and various sensors, and coaxiality detection in the mechanical transmission system And motor forward and reverse settings.

[0063] 2) One end of the test piece 5 is connected to t...

Embodiment 3

[0069] The size of the selected cylindrical test piece is: length 160mm, diameter 10mm. The material of the experimental piece is a polymer (polytetrafluoroethylene) material.

[0070] The set freezing temperature is -5°C, the pressure of the air delivery pipeline is 0.6MPa, and the pressure of the pure water delivery pipeline is 0.3MPa. According to the actual performance specification of the nozzle, the corresponding liquid water droplet diameter is 10μm. Set the freeze time to 9 minutes. Freezing time after freezing is 5 minutes.

[0071]1) Debug and inspect the corresponding parts of the whole device: reliability detection of the adjustment switch in the device, operation test of the KingView monitoring program, reliability detection of the data acquisition module and various sensors, and coaxiality detection in the mechanical transmission system And motor forward and reverse settings.

[0072] 2) One end of the test piece 5 is connected to the shaft 7 by a coupling 6, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com