Method for determining shrinkage rate of glass

A technology of shrinkage and glass, which is applied in the direction of measuring devices, instruments, thermal expansion coefficient of materials, etc., can solve problems such as difficult to measure glass shrinkage, glass has bubbles, irregular shape, etc., and achieves high reproducibility, high precision, The effect of accurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] In the method of the present invention, preferably, in step (1), the preparation method of the glass filament to be tested comprises: drawing the glass into a glass filament, and after cutting, firing the two ends of the glass filament into a spherical shape.

[0030] The glass melted from different materials is drawn into glass filaments with uniform diameter and the same diameter with a wire drawing machine. Preferably, the diameter of the drawn glass filaments is 0.3-1mm, more preferably 0.5-0.8mm. The shrinkage rate is measured by the method of the present invention, which is used to measure the performance of the glass in the development process. During the measurement, glass filaments with uniform thickness are selected as the experimental object, and their diameters are accurately measured under a microscope. The diameters of the glass filaments measured in the same batch are almost the same. , the error is controlled within 0.1mm.

[0031] Preferably, the cut gl...

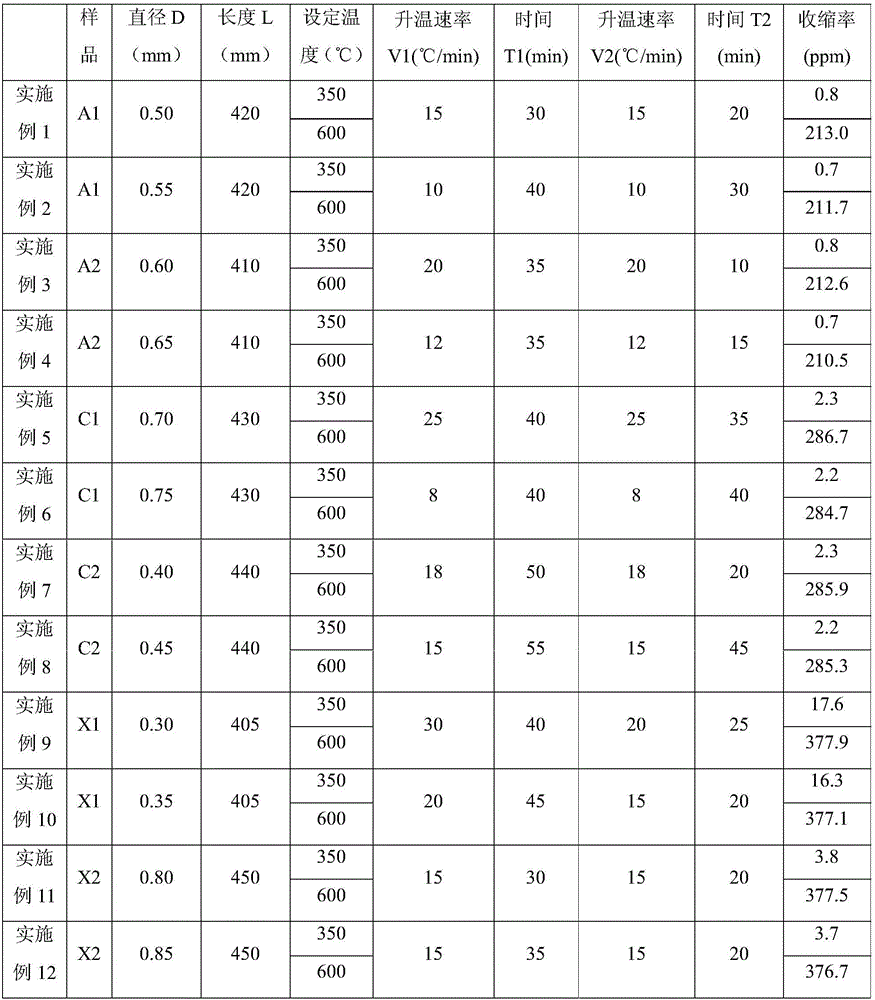

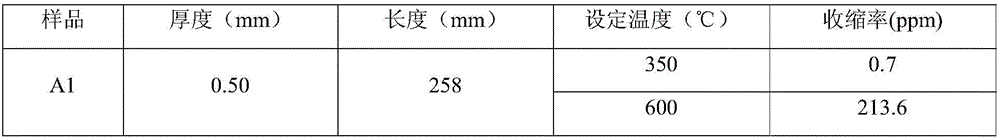

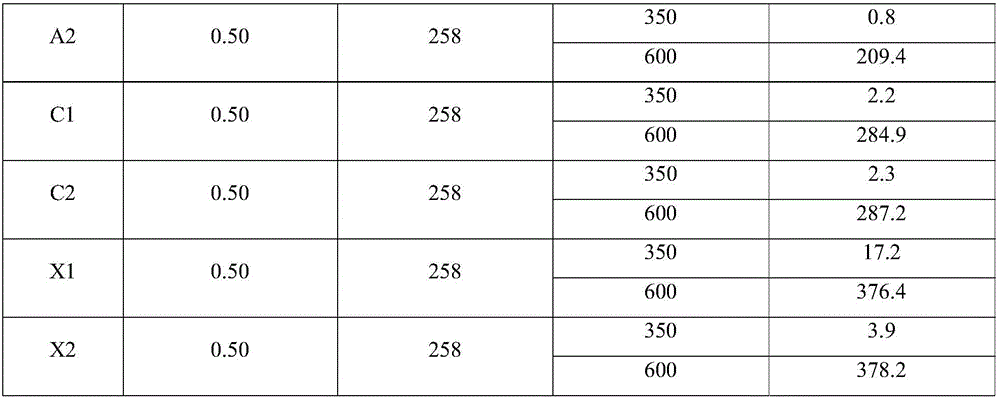

Embodiment 1-12

[0050] This example is used to illustrate the method for measuring glass shrinkage of the present invention.

[0051] (1) After melting the TFT-LCD glass substrate to be tested, use a wire drawing machine to draw glass filaments with a diameter of D (mm), cut the glass filaments to a length of L (mm), and burn the two ends of the obtained glass filaments Become a spherical shape with a diameter of 7mm to obtain the glass filament to be measured, and the length L1 of the glass filament to be heat-treated in the glass filament to be measured is 350mm;

[0052] (2) Wrap the glass fiber to be tested with thermal insulation cotton and put it into a precision annealing furnace, raise the temperature of the glass fiber to be tested to the annealing point temperature at a heating rate V1 (°C / min), and keep it warm at the annealing point temperature T1 (min), and then Cool down to 25°C with the furnace;

[0053] (3) After step (2) is annealed, the two ends of the glass fiber to be tes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com