Method for designing ultrasonic torsion fatigue testing specimen with uniform section

A technology of torsional fatigue and design method, which is applied in the direction of analyzing solids using sound waves/ultrasonic waves/infrasonic waves, can solve the problems of enlarging the maximum torsional stress area and the difficulty in obtaining accurate ultra-high cycle torsional fatigue test data, and achieves improved accuracy, The effect of enriching sample types and expanding the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments of the present invention will be described in detail below, and the described embodiments are exemplary and intended to explain the present invention, but should not be construed as limiting the present invention.

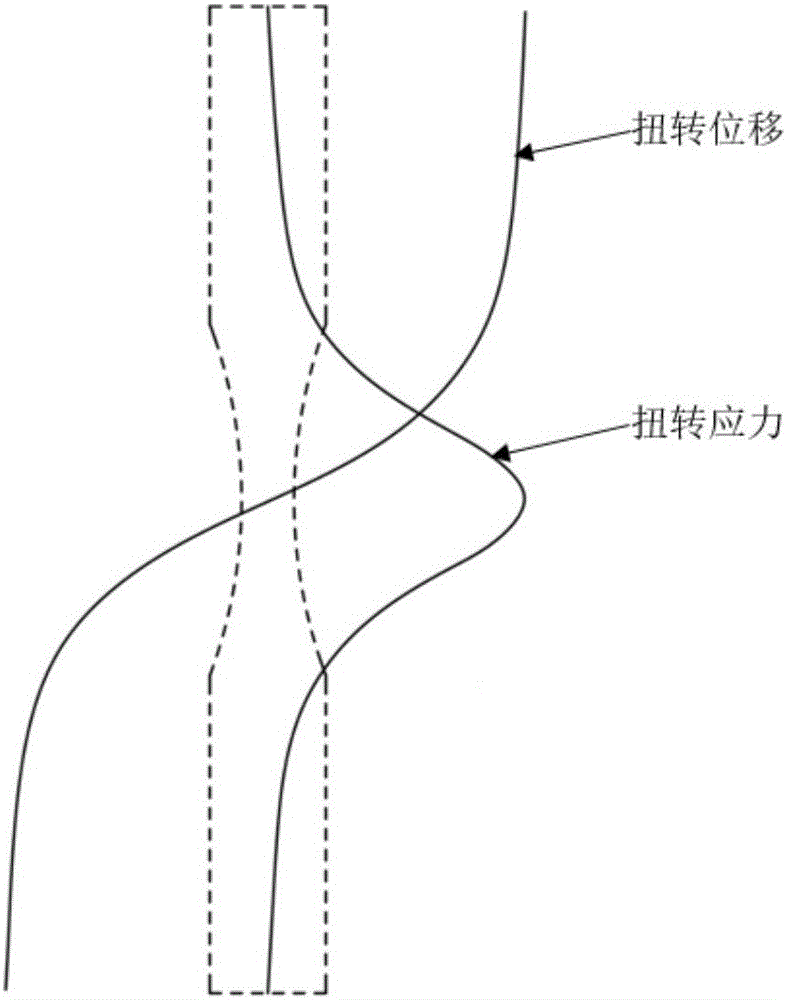

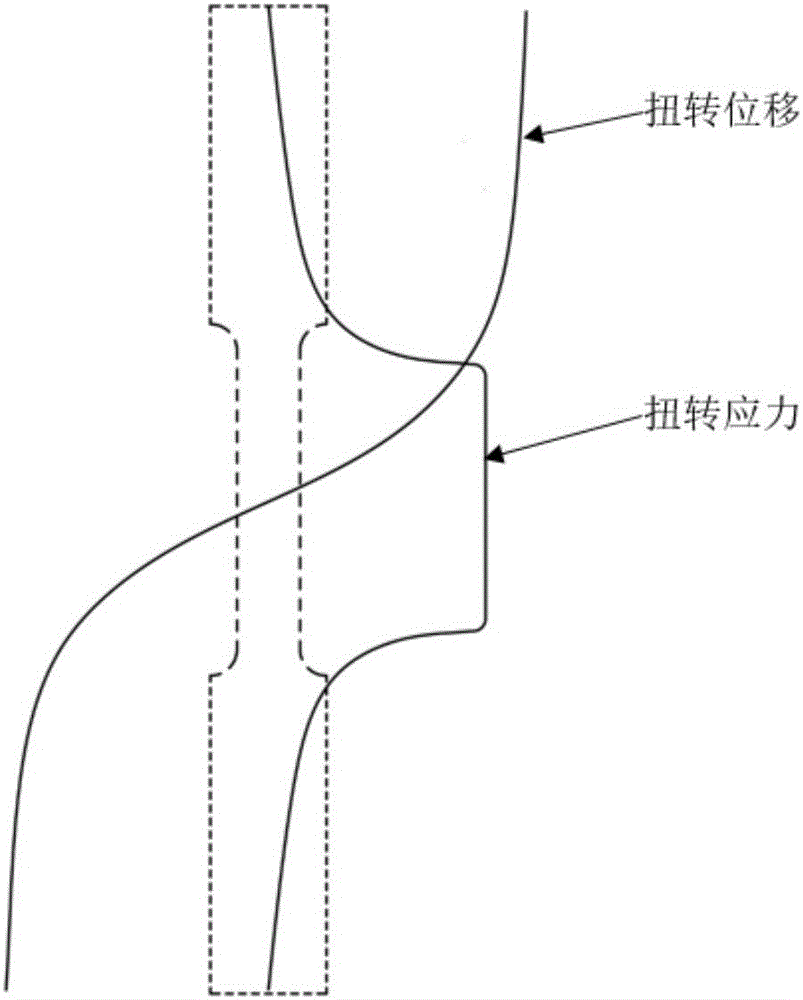

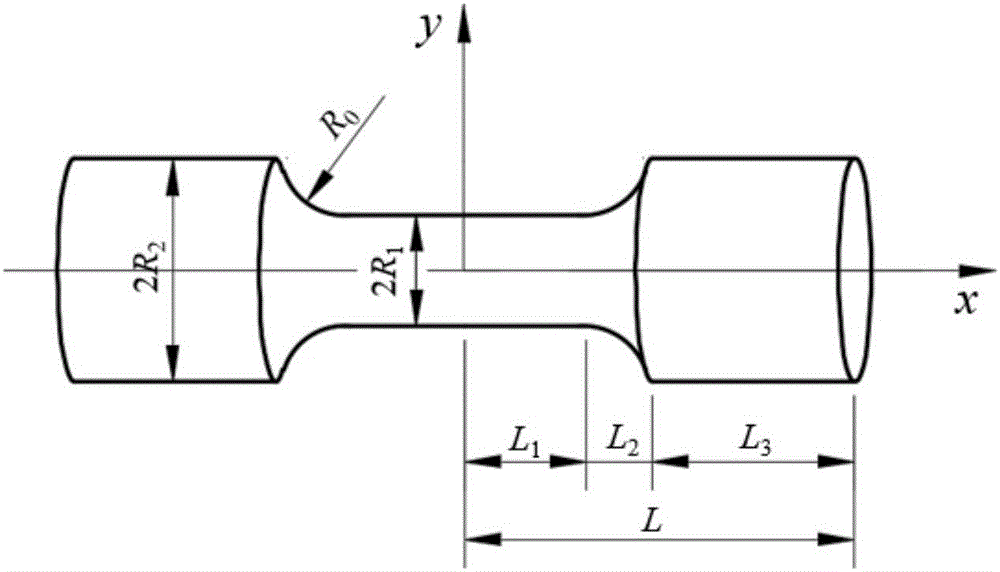

[0027] At present, the ultrasonic torsional fatigue test mainly adopts dog-bone ultrasonic torsional fatigue specimens, such as figure 1 As shown, the maximum torsional stress is obtained at the middle minimum section, but for most materials containing defects (inclusions, shrinkage cavities, internal structure inhomogeneity), the maximum isostress zone of the dog-bone ultrasonic torsional fatigue specimen is too small, and it is difficult to obtain Accurate test data, therefore, in order to obtain accurate ultrasonic fatigue test data, need to increase the maximum torsional stress area of the ultrasonic torsional fatigue sample, so the present invention designs a kind of equal section ultrasonic torsional fatigue sample, such as figure 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com