Special-shaped plate part hot precision forging forming mould cavity correction method

A technology for disc parts and forming dies, which is applied in special data processing applications, instruments, and electrical digital data processing, etc., and can solve problems such as low forming precision, heating of forgings and dies, complex force deformation, and difficult control of processing accuracy. It achieves the effect of improving the forming precision of hot precision forging, the calculation method is simple and fast, and the finishing allowance is reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, so as to facilitate a clearer understanding of the present invention, but they do not limit the present invention.

[0027] combine figure 1 The invention discloses a method for correcting a mold cavity of a hot precision forging forming mold for special-shaped disk parts, which comprises the following steps:

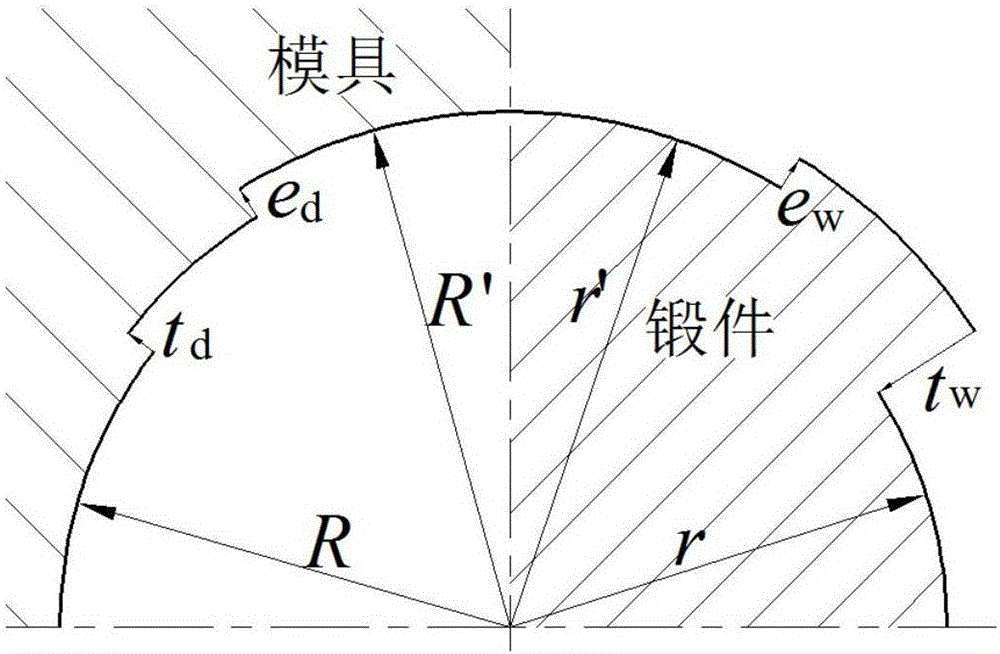

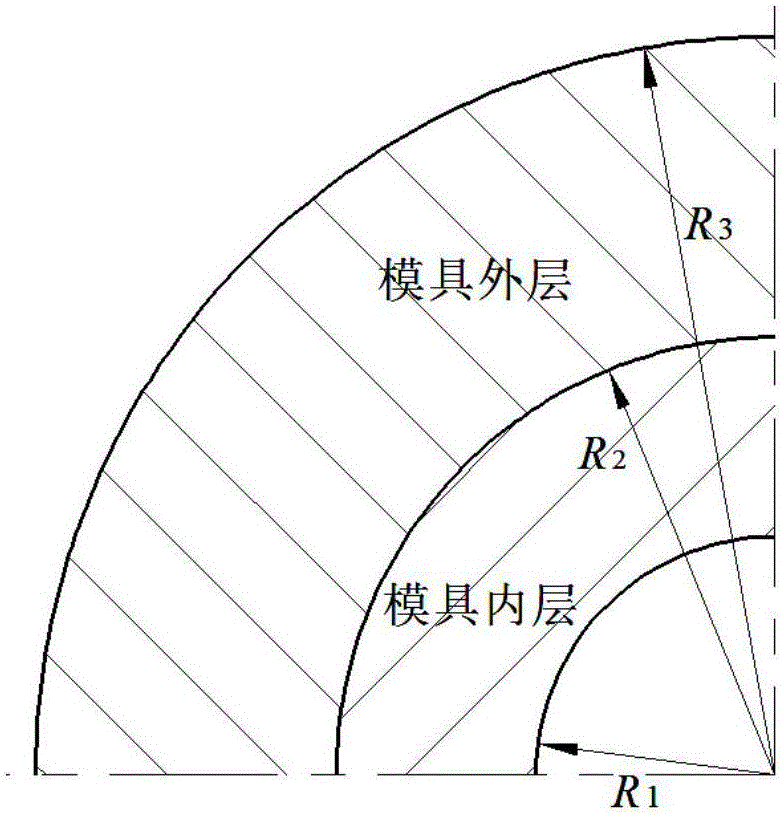

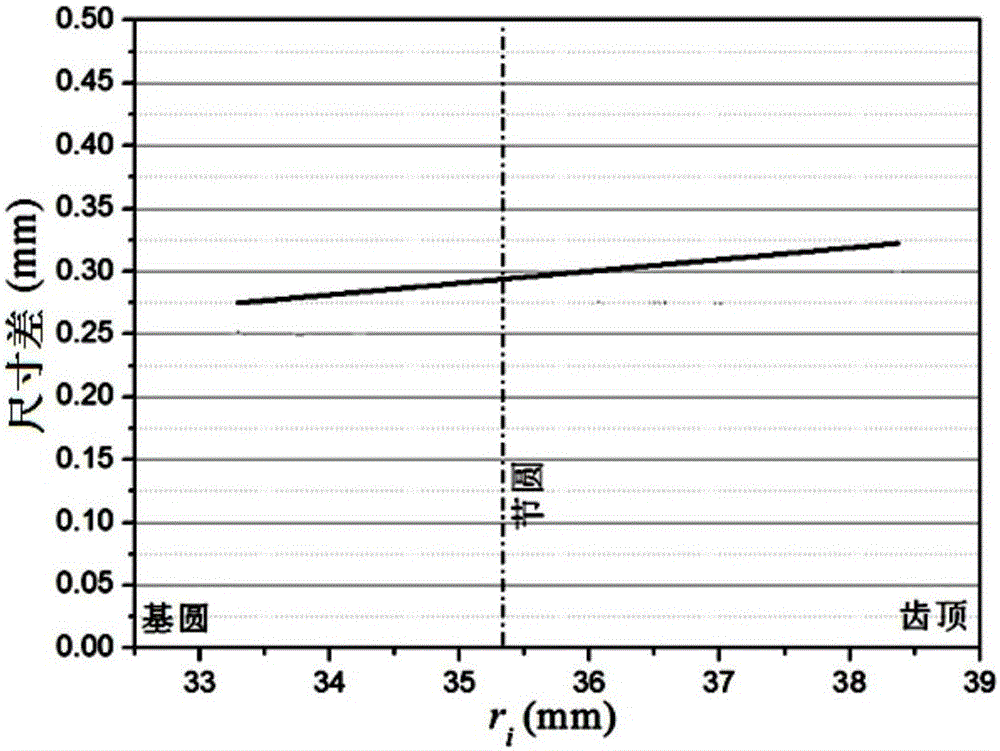

[0028] 1) Construct a mathematical model based on the contour deformation of forgings and dies during hot forging. The mathematical model includes four parts: die preheating expansion t d , Forging cold shrinkage t w , mold elastic expansion e d And springback after forging out of the mold w , mold preheating expansion t d is the size of the mold cavity that will increase due to thermal expansion due to mold preheating before forging, and the elastic expansion of the mold under force e d is the elastic expansion of the mold ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flow stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com