Dynamics simulation optimization method and device of heavy haul train

A dynamic simulation and optimization method technology, applied in design optimization/simulation, special data processing applications, instruments, etc., can solve the problems of complex modeling process, difficult data processing, difficult real-time and data synchronization, etc. The effect of reducing the number of calculations, realizing real-time and data synchronization, and reducing the difficulty of data processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

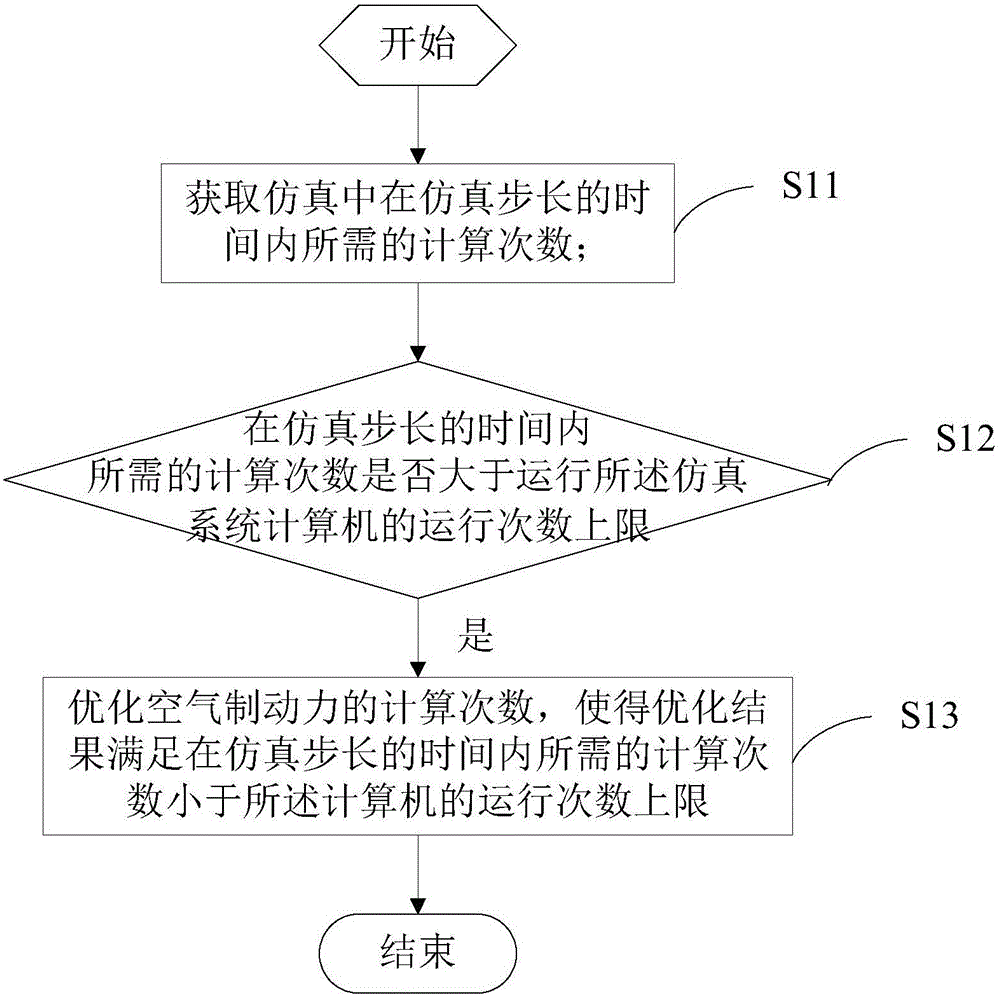

[0051] see figure 1 , figure 1It is a flow chart of a long train dynamics simulation optimization method disclosed in Embodiment 1 of the present invention. The method is applied to a long train dynamics simulation system, and the method includes the following steps:

[0052] Step S11: Obtain the number of calculations required within the time of the simulation step in the simulation; the number of calculations required within the time of the simulation step is the number of traction calculations used for each simulation, and the power used for each simulation. The product of braking calculation times, running resistance calculation times for each simulation, air braking force calculation times for each simulation, coupler force calculation times for each simulation and additional resistance calculation times for each simulation;

[0053] Specifically, the long train dynamics simulation system inputs the running resistance parameters of the long train, the traction-braking cu...

Embodiment 2

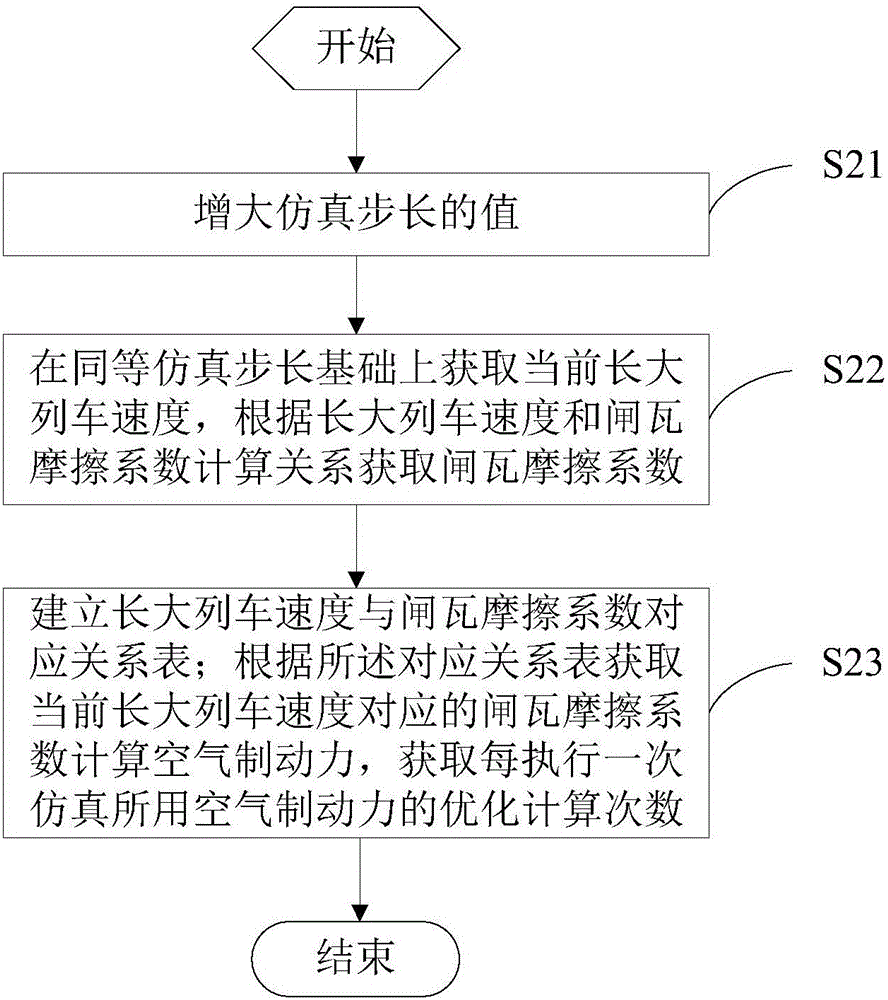

[0064] Based on the above-mentioned a kind of long train dynamics simulation optimization method disclosed in Embodiment 1 of the present invention, such as figure 1 The number of calculations of the optimized air braking force in the number of calculations of the optimized air braking force S13 is shown, and its specific execution process is as follows: figure 2 , mainly including the following steps:

[0065] Step S21: increase the value of the simulation step size to reduce the calculation times of the air braking force used for each simulation;

[0066] Specifically, the initial value of the simulation step size can be set to 0.002 seconds, 1s=1000ms, that is to say, a calculation is performed every 5ms, and the value of the simulation step is increased, that is, the calculation is performed within 1s. The time can reduce the difficulty of data processing when the computer runs the simulation system.

[0067] Step S22: Obtain the current speed of the long train on the b...

Embodiment 3

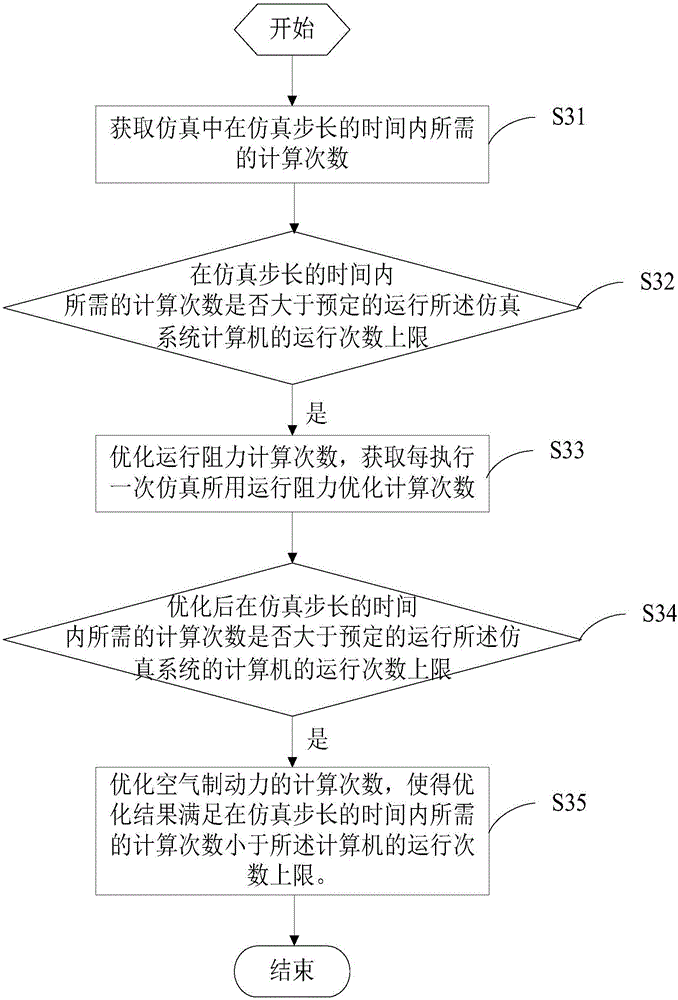

[0091] see image 3 , image 3 It is a flow chart of a long train dynamics simulation optimization method disclosed in Embodiment 3 of the present invention, and the method includes:

[0092] Step S31: Obtain the number of calculations required within the time of the simulation step in the simulation; the number of calculations required within the time of the simulation step is the number of traction calculations used for each simulation, and the power used for each simulation. The product of braking calculation times, running resistance calculation times for each simulation, air braking force calculation times for each simulation, coupler force calculation times for each simulation and additional resistance calculation times for each simulation;

[0093]Specifically, the long train dynamics simulation system inputs the running resistance parameters of the long train, the traction-braking curve parameters of the long train, the coupler slowdown model parameters of the long tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com