Battery intelligent maintenance system

An intelligent maintenance and storage battery technology, applied in secondary battery repair/maintenance, secondary battery, battery temperature control, etc., can solve the problem of accelerated aging of battery packs, poor consideration of functional modules, reduction of battery pack discharge time and service life, etc. problem, to achieve the effect of reducing the equivalent series resistance ESR of the capacitor, realizing voltage balance or voltage boost, prolonging the discharge time and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

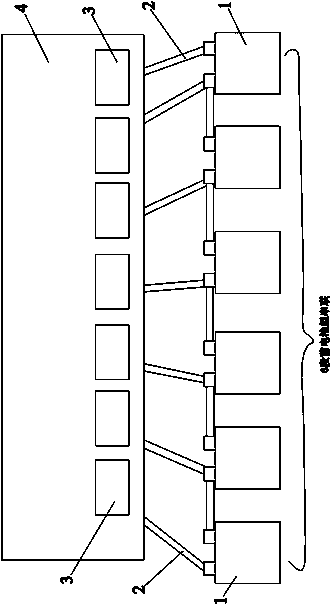

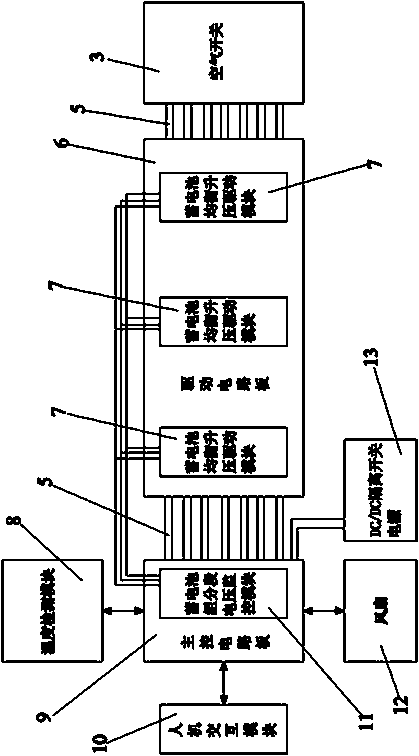

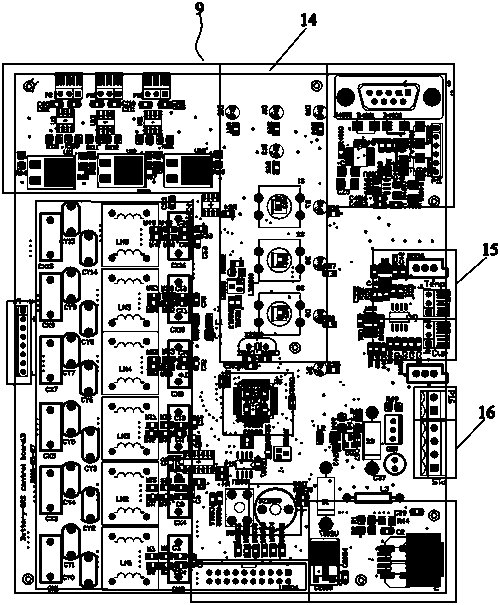

[0033] Battery intelligent maintenance system, such as Figure 1-9 As shown, it includes a battery group divided into 6 sections by 24 batteries 1, a battery group section voltage monitoring module 11 fixed on the main control circuit board 9, and a battery balanced boost drive fixed on the drive circuit board 6. The module 7, the main control circuit board 9 and the driving circuit board 6 are all fixedly arranged in the chassis 4, the battery group segment voltage monitoring module 11 and the battery equalization boost driving module 7 are all connected to the battery group, and the battery group segment voltage monitoring module 11 is connected to the battery equalization boost drive module 7; the battery group segment voltage monitoring module 11 monitors the terminal voltage of the 6-segment battery group through the battery group segment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com