Soymilk machine cup body assembly and soymilk machine

A soymilk machine and cup technology, which is applied in kitchen utensils, household utensils, beverage preparation devices, etc., can solve the problems of heat loss, achieve the effects of small energy loss, increase the probability of collision with materials, and improve the crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

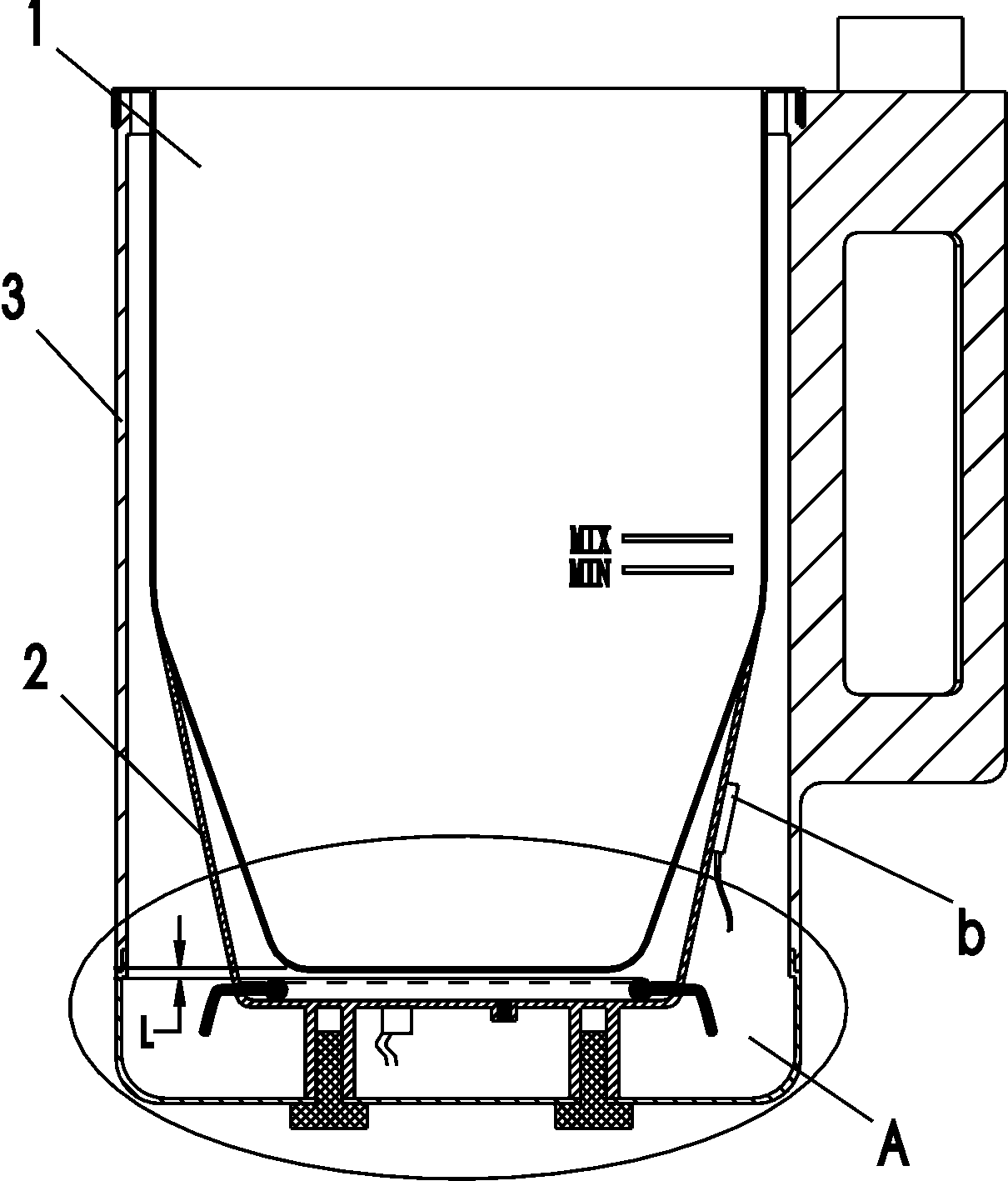

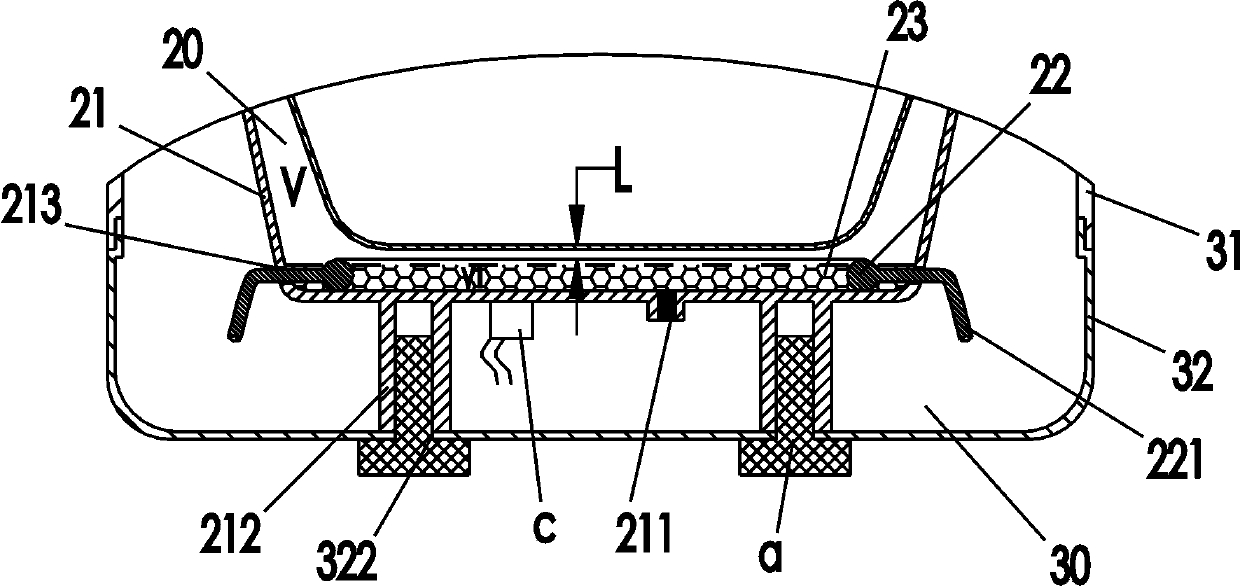

[0026] Such as figure 1 , figure 2 Shown is a schematic structural view of the first embodiment of the present invention. A soymilk machine cup assembly, the soymilk machine cup assembly includes a milk cup 1, a superconducting heating device 2 arranged at the bottom of the milk cup 1, and a superconducting heating device 2 installed on the outside of the milk cup 1 and accommodated in the The heat-insulating shell 3 of its inner cavity, the superconducting heating device 2 includes a housing 21 formed with a vacuum chamber 20, a heating body 22 arranged in the vacuum chamber 20 and a superconducting medium injected into the vacuum chamber 20 23. An injection hole 211 is provided on the outer wall of the housing 21, through which the superconducting medium 23 is injected into the vacuum cavity 20, and after the injection is completed, the injection hole 211 is sealed.

[0027] In this embodiment, the shell 21 is welded and covered on the lower outside of the pulp cup 1, and...

Embodiment 2

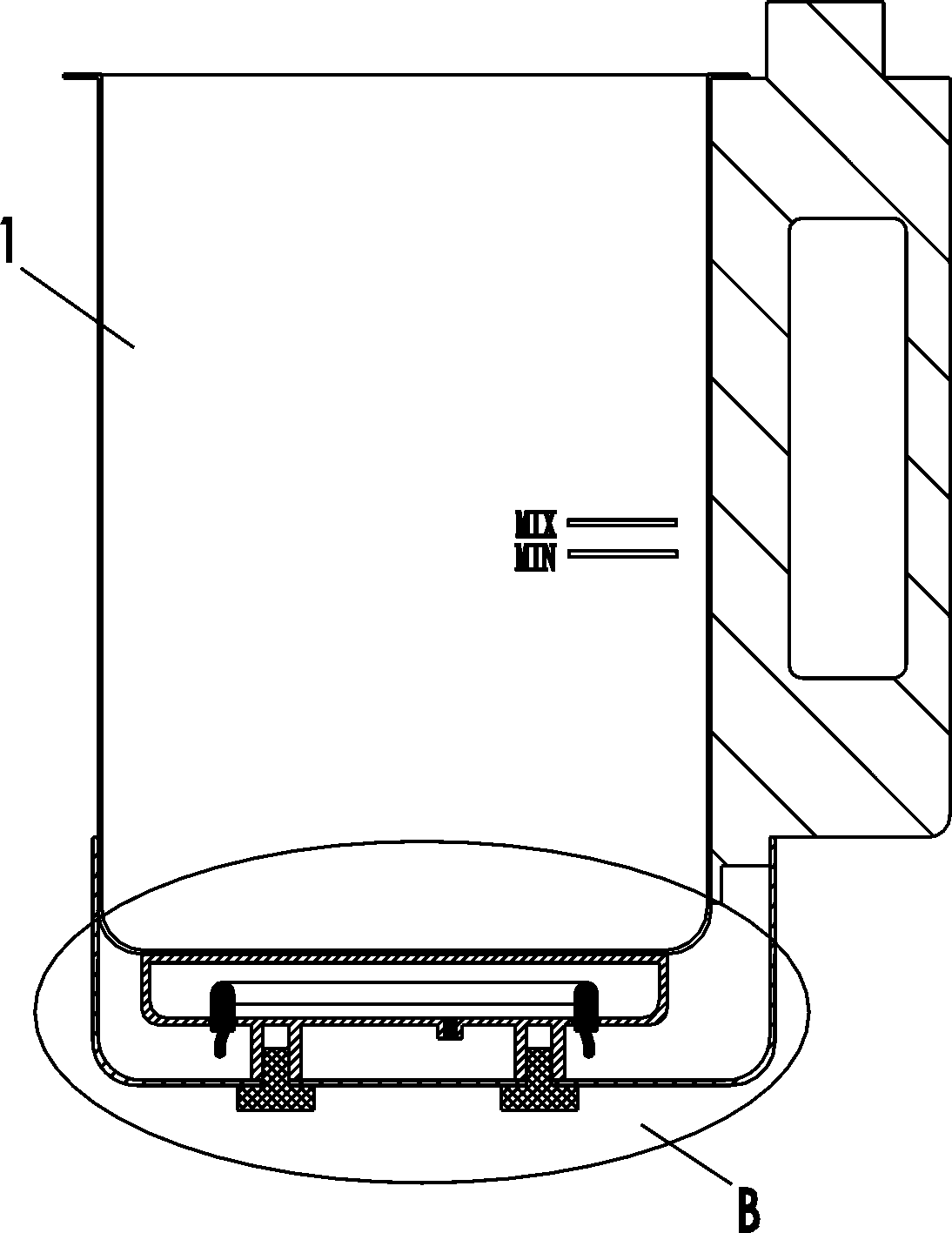

[0037] Such as image 3 , Figure 4 Shown is the second embodiment of the present invention. The difference from Embodiment 1 is that in this embodiment, the superconducting heating device is located on the bottom outer surface of the plasma cup to heat the bottom of the plasma cup, and the heating body 22 is directly fixed to the through hole 213 of the housing 21 , and the sealing process between the heating body 22 and the through hole 213, the connecting wire 221 drawn from the end of the heating body 22 is directly exposed and connected in series with the fuse and the temperature controller (not shown in the figure). And the vacuum chamber 20 is only formed by sealing the housing 21, and the outer surface of the bottom of the pulp cup 1 is closely attached to the outer wall of the housing 21, and at the same time, the heat insulation shell is directly fixed on the bottom of the pulp cup 1 The base 32 wraps the superconducting heating device in its inner cavity 30 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com