Tire production device

A production equipment and tire technology, applied in the field of tire production, can solve problems such as complex process routes, reduced tire tread strength, uneven materials, etc., and achieve the effects of improving dimensional accuracy, improving uniformity, and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

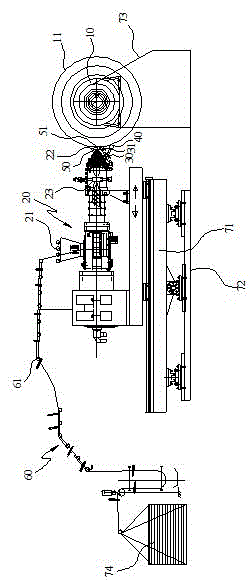

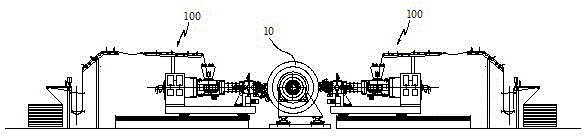

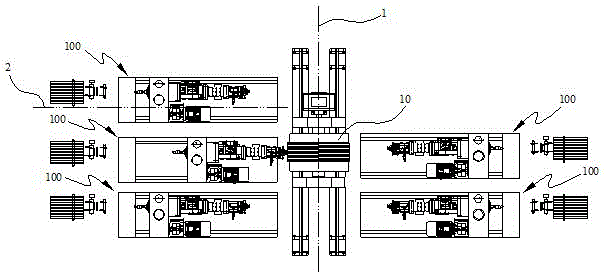

[0026] like figure 1 and figure 2 As shown, the tire production equipment in this embodiment includes a building drum 10 and a glue supply device 100 , and the glue supply device 100 includes a glue supply extruder 20 and a pressing mechanism 30 . The forming drum 10 has an annular forming surface 11, the forming drum 10 is pivotably arranged, the pivot axis of the forming drum 10 coincides with the axis of the annular forming surface 11 and extends along a horizontal first direction. The rubber supply extruder 20 includes a rubber material inlet 21 and a rubber strip extrusion port 22 , and the rubber strip extrusion port 22 faces the annular molding surface 11 . The melt metering pump 23 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com