Sand-discharging submerged pump

A technology for sediment discharge submersible pump and pump body, applied in the direction of pumps, pump devices, pump components, etc., can solve the problems of restricting the renewal and development of submersible pumps, and achieve the effect of normal temperature rise, reduced heat generation, and reduced end face specific pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

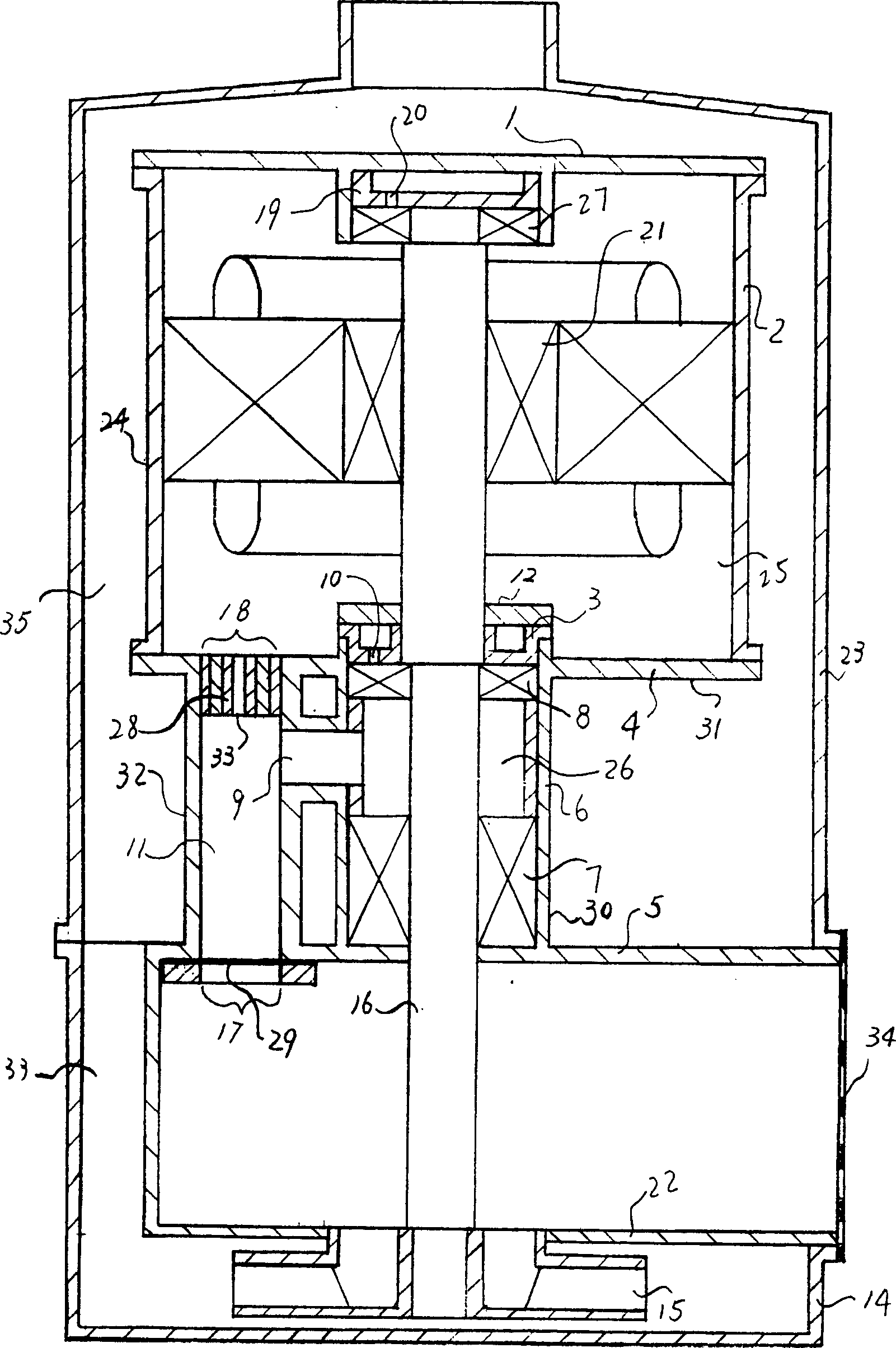

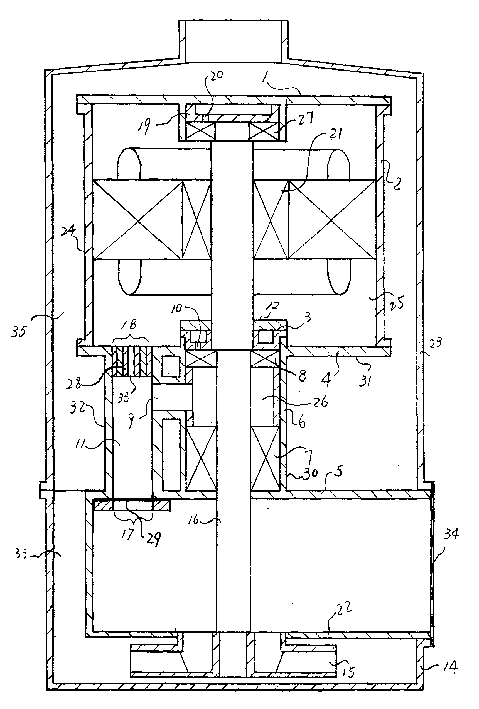

[0011] Attached below figure 1 The present invention is further described.

[0012] figure 1 Among them, the sand discharge submersible pump includes a pump body 14 , a pump shaft 16 , an impeller 15 and a dry motor 24 . Its dry motor 24 is above the pump body 14 . The lower cover plate 5 of the mechanical seal chamber 7 extends to the bottom flange of the casing 23 and supports the filter screen 34 together with the upper cover plate 22 of the pump body 14 and the pump body flange. The suction port of the pump body faces upwards. The pump body outlet pipe 33 is connected to the annular cavity 35 formed by the casing 23 and the motor 24 covered by the motor 24 outside. exist figure 1 Among them, the oil storage tank 19 in the motor upper end cover 1 bearing chamber 27, it is placed on the bearing top in the bearing chamber 27, has an oil drip hole 20 on its bottom. The oil storage tank 3 in the lower end cover 4 bearing chambers 8 is placed above the bearing in the beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com