UPVC (unplasticized polyvinyl chloride) hollow-wall internal spiral tube

An inner spiral tube and hollow wall technology, which is applied in the field of UPVC hollow wall inner spiral tube, can solve the problems of unachievable and unsatisfactory sound-absorbing effect, and improve the drainage capacity, stabilize the pressure fluctuation, and increase the strength of the tube wall. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

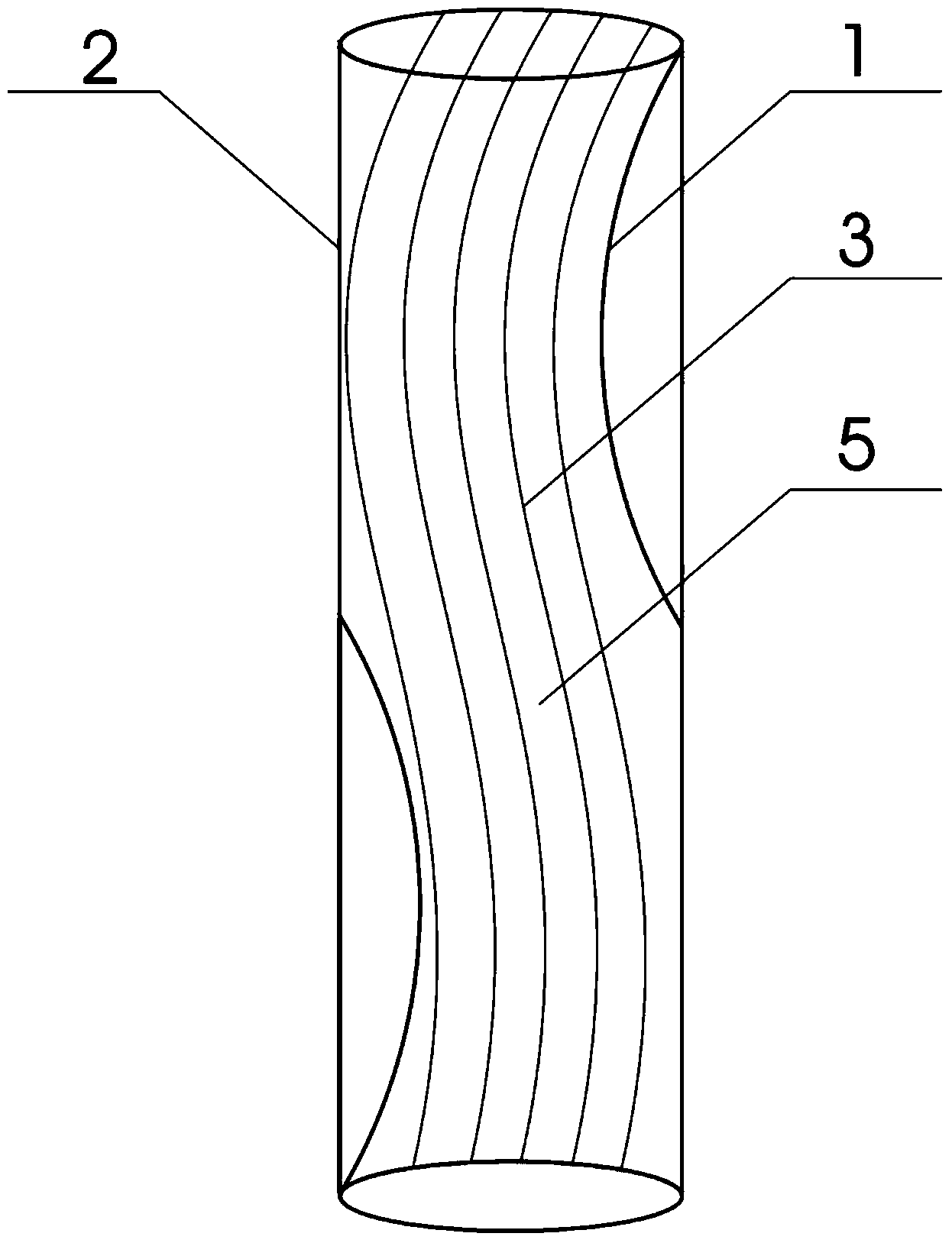

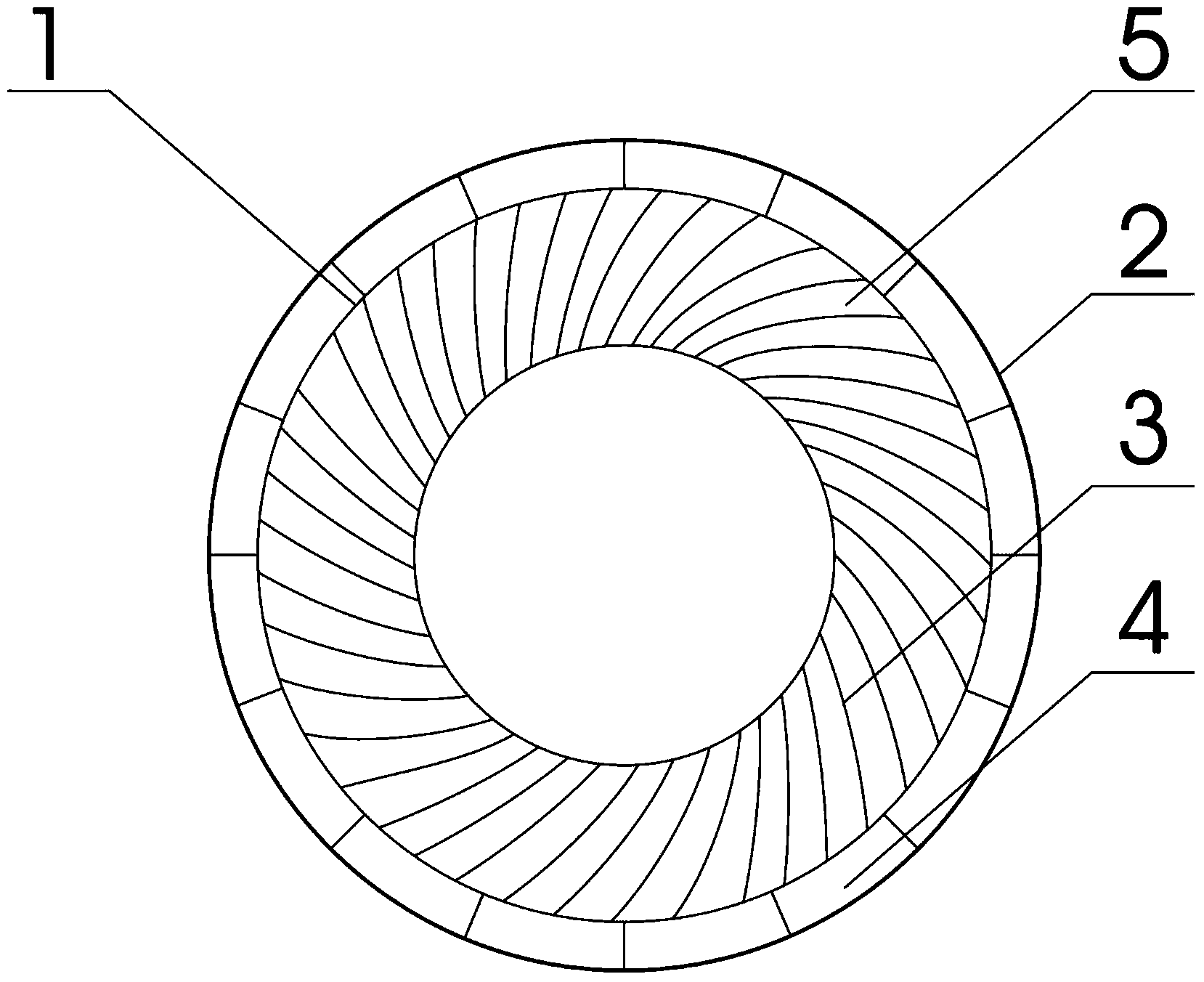

[0021] A UPVC hollow-wall internal spiral pipe, the pipe material is cylindrical, the pipe wall of the pipe material includes an inner pipe wall 1 and an outer pipe wall 2, and there is a cavity 4 between the inner pipe wall 1 and the outer pipe wall 2 ; The inner pipe wall 1 is a spiral water guide wall 5; the spiral angle of the spiral water guide wall 5 of the inner pipe wall 1 is 35° of the vertical angle; the inner pipe wall 1 and the outer pipe wall 2 A number of ribs are evenly spaced to divide the hollow into several cavities 4; the number of ribs provided between the inner pipe wall 1 and the outer pipe wall 2 and the spiral water guide wall 5 of the inner pipe wall The helix angles are parallel; the top of the section of the helical water guide wall 5 of the inner pipe wall 1 is a circular arc transition, and the helical water guide wall 5 is helical around the axis of the pipe; the pitch of the helix angle is 800mm; The cross-section of the spiral water guide wall 5...

Embodiment 2

[0023] A UPVC hollow-wall internal spiral pipe, the pipe material is cylindrical, the pipe wall of the pipe material includes an inner pipe wall 1 and an outer pipe wall 2, and there is a cavity 4 between the inner pipe wall 1 and the outer pipe wall 2 ; The inner pipe wall 1 is a spiral water guide wall 5; the spiral angle of the spiral water guide wall 5 of the inner pipe wall 1 is 45° of the vertical angle; the inner pipe wall 1 and the outer pipe wall 2 A number of ribs are evenly spaced to divide the hollow into several cavities 4; the number of ribs provided between the inner pipe wall 1 and the outer pipe wall 2 and the spiral water guide wall 5 of the inner pipe wall The helix angles are parallel; the top of the section of the helical water guide wall 5 of the inner pipe wall 1 is a circular arc transition, and the helical water guide wall 5 is helical around the axis of the pipe; the pitch of the helix angle is 850mm; The cross-section of the spiral water guide wall 5...

Embodiment 3

[0025] A UPVC hollow-wall internal spiral pipe, the pipe material is cylindrical, the pipe wall of the pipe material includes an inner pipe wall 1 and an outer pipe wall 2, and there is a cavity 4 between the inner pipe wall 1 and the outer pipe wall 2 ; The inner pipe wall 1 is a spiral water guide wall 5; the spiral angle of the spiral water guide wall 5 of the inner pipe wall 1 is 60° of the vertical angle; the inner pipe wall 1 and the outer pipe wall 2 A number of ribs are evenly spaced to divide the hollow into several cavities 4; the number of ribs provided between the inner pipe wall 1 and the outer pipe wall 2 and the spiral water guide wall 5 of the inner pipe wall The helix angles are parallel; the top of the section of the helical water guide wall 5 of the inner pipe wall 1 is a circular arc transition, and the helical water guide wall 5 is helical around the axis of the pipe; the pitch of the helix angle is 900mm; The cross-section of the spiral water guide wall 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com