Mixed gas condensation separation separation mass storage booster energy storage device and method and practical system

A mixed gas, condensation separation technology, applied in steam engine installations, refrigeration and liquefaction, refrigerators, etc., can solve the problems of unclear commercialization prospects, difficulties in fuel-fired power plants, and high investment and operation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

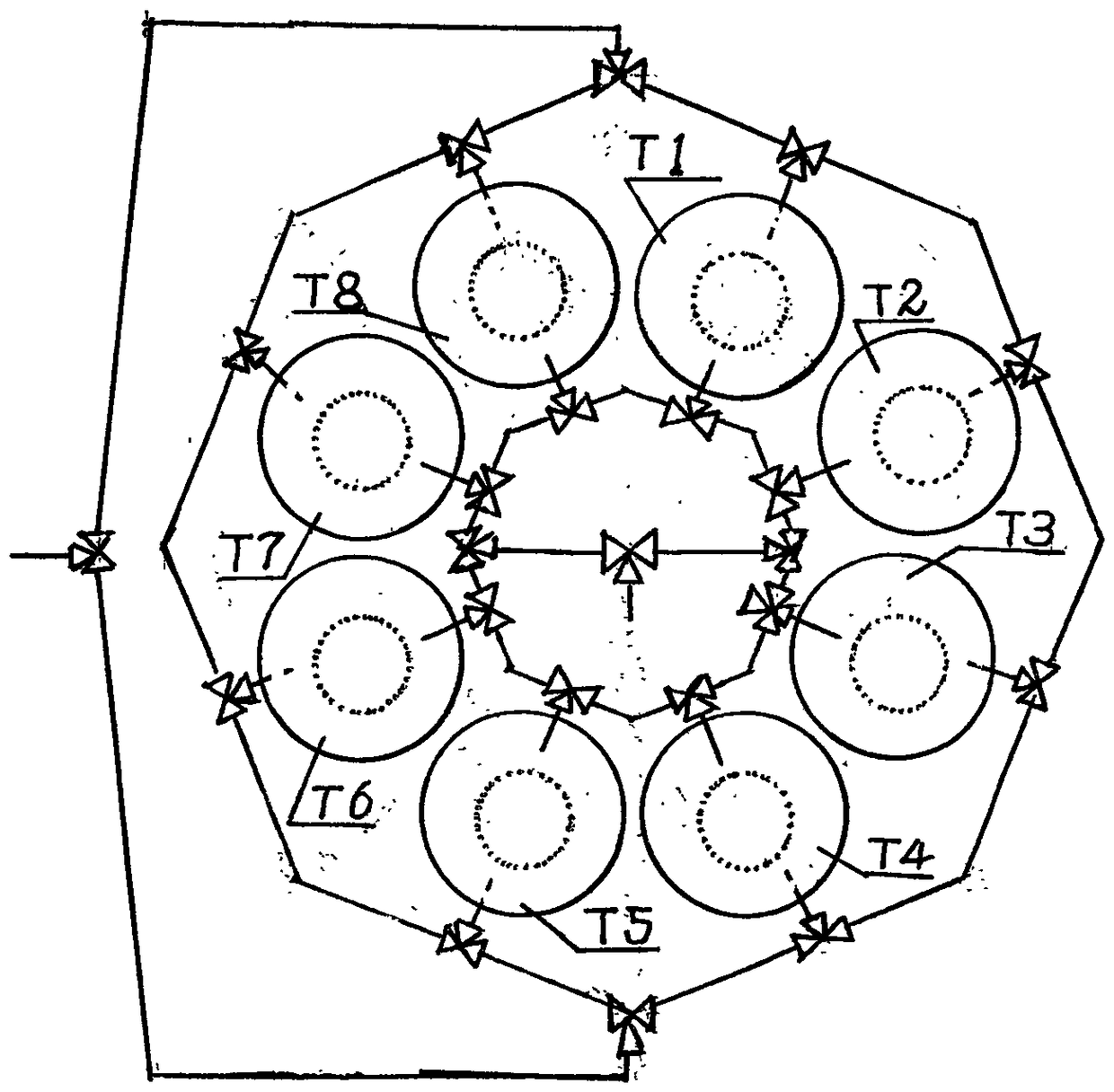

[0063] Wind Power Plant Air Separation Energy Storage Power Station

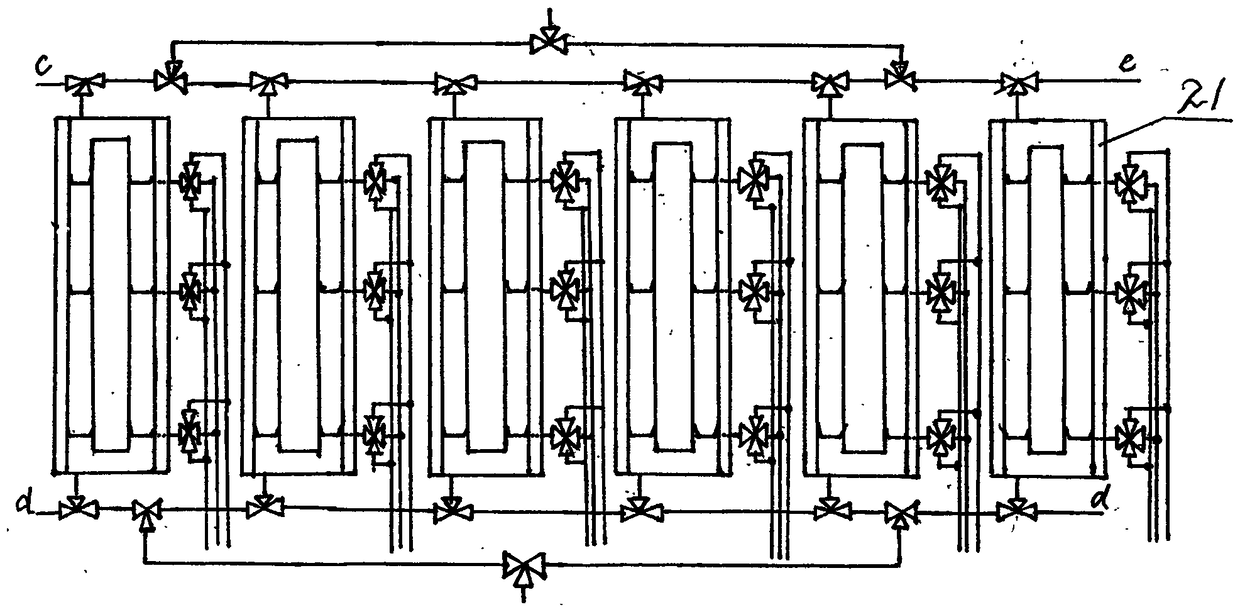

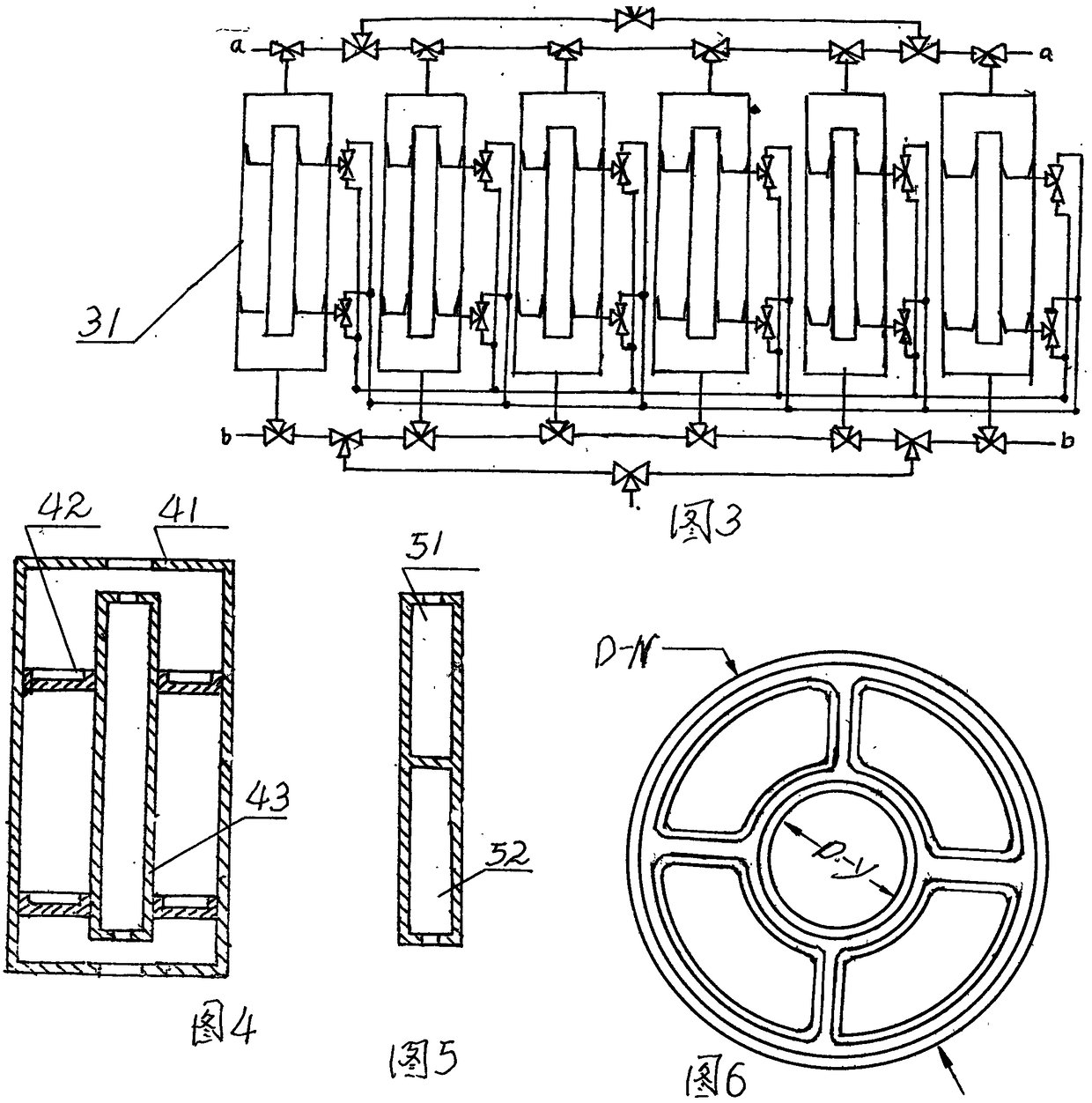

[0064] When the wind power plant has excess electric energy, the electric energy is input to the air separation energy storage power station, which is supplied to the motor to drive the compressor (31) to realize the energy storage task. When the peak power consumption comes, the air separation energy storage power station generates electricity and transmits it to the power grid . When the grid fails, the air energy storage power station can quickly provide power support for the grid within a few milliseconds and protect the safe operation of the grid.

[0065] Photovoltaic power plant Air separation energy storage power station

[0066] When the photovoltaic power plant has excess electric energy, the electric energy is input to the air separation energy storage power station, which is supplied to the electric motor to drive the compressor (31) to realize the energy storage task. When the power grid fails...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com