Device for electronic beams to assist plasma in sputtering coating of flexibility copper-clad plate

A flexible copper-clad laminate and plasma sputtering technology, which is applied in the equipment field of ion sputtering flexible copper-clad laminates, can solve problems such as unusable, high probability of scrap, poor film adhesion, etc., to achieve improved peel strength and improved production efficiency , The effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

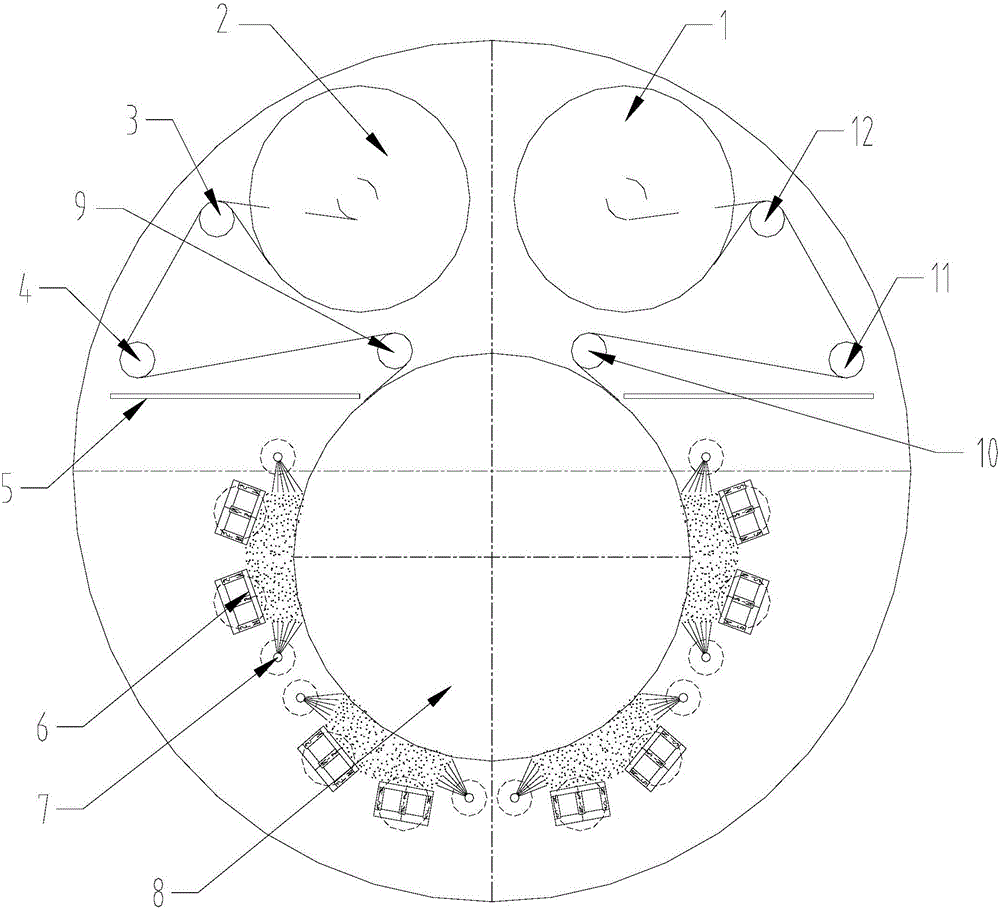

[0022] The present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

[0023] For the convenience of description, the up, down, left, and right directions mentioned below are the same as figure 1 The up, down, left, and right directions are the same.

[0024] combine figure 1 As shown, the equipment for electron beam-assisted plasma sputtering of flexible copper-clad laminates includes a vacuum chamber and partitions all arranged in the vacuum chamber, multiple electron beam auxiliary devices, multiple pairs of magnetron targets, multiple high-frequency AC power supplies, and base Materials, running circuit components used to control the operation of substrates. The running line assembly includes unwinding rollers, first guide rollers, first detection rollers, second guide rollers, water-cooled drums, third guide rollers, second detection rollers, fourth guide rollers, Winding roller. Multiple pairs of mag...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap