Liquidometer calibration device

The technology of a calibration device and a liquid level gauge is applied in the field of automatic instruments, which can solve the problems of energy waste, low work efficiency, low work efficiency, etc., and achieve the effects of simple device structure, high accuracy and operation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

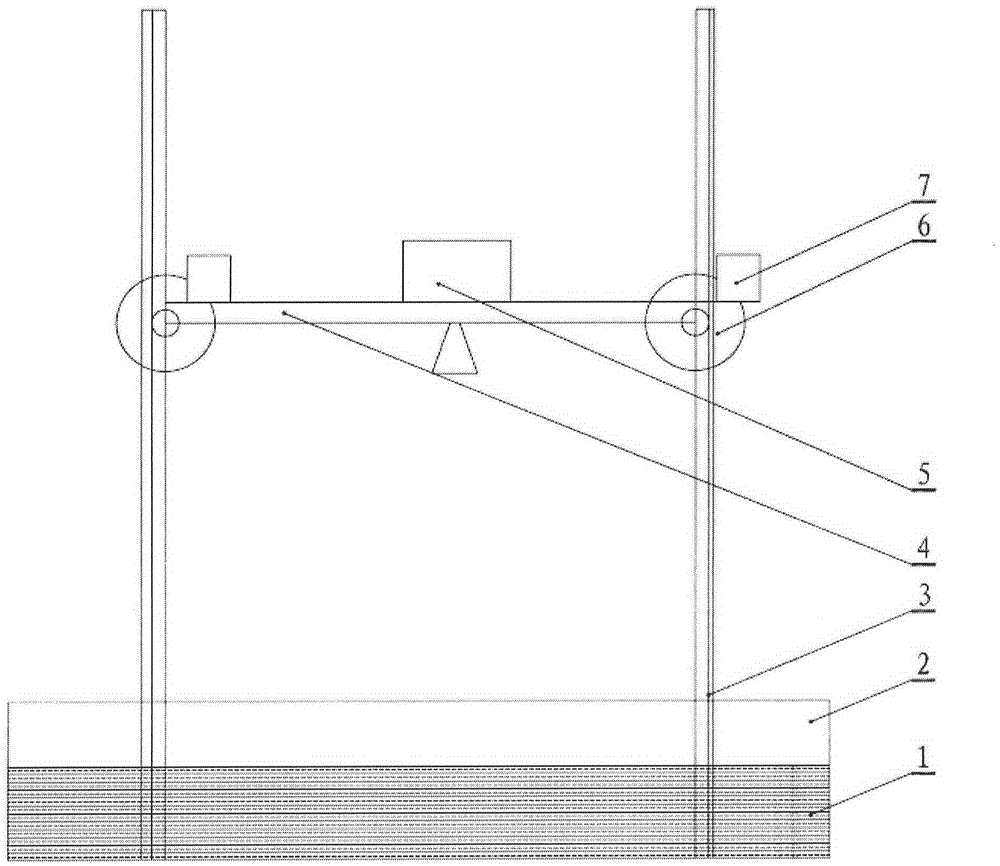

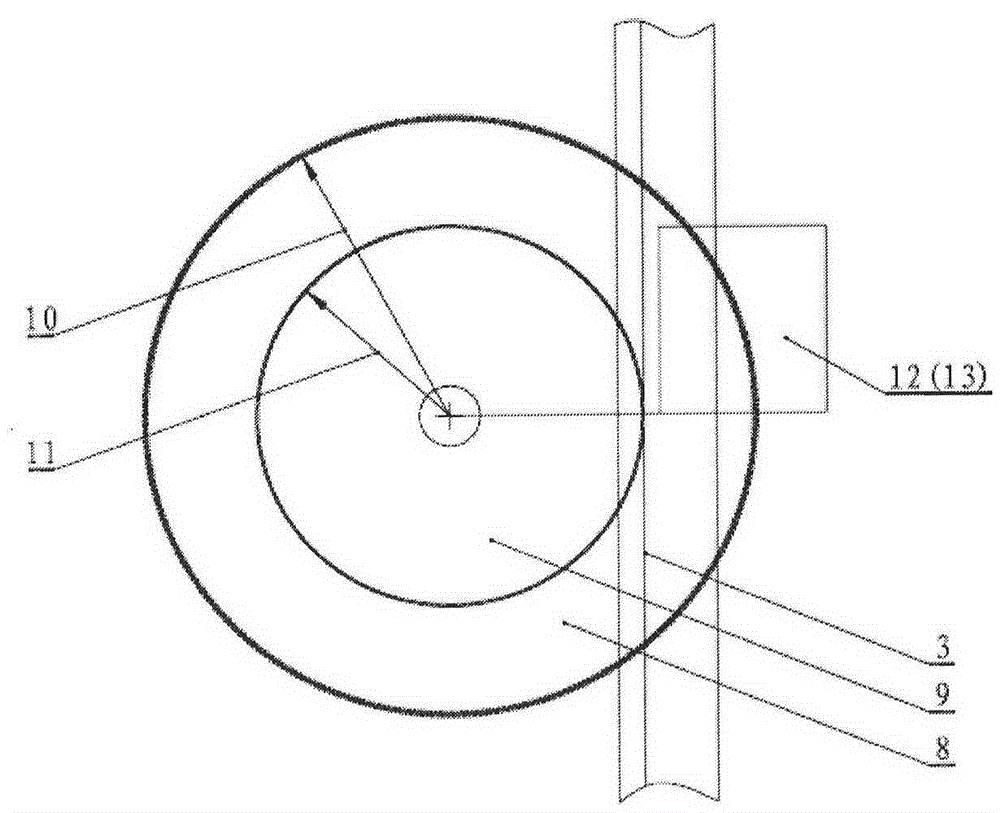

[0014] The above and other technical features and advantages of the present invention will be described in more detail below with reference to the accompanying drawings and embodiments.

[0015] like figure 1 and 2 As shown, a liquid level gauge calibration device of the present invention, said liquid level gauge calibration device includes vertical guide rails 3 at both ends and a working lifting platform 4, and a displacement sensing mechanical amplifier 6 is respectively provided at both ends of the working lifting platform 4 , the displacement sensing mechanical amplifier 6 includes a displacement sensing disk 9, the displacement sensing disk 9 is coaxially connected to a grating switch disk 8, the radius of the grating switching disk 8 is greater than the radius of the displacement sensing disk 9, and the displacement sensing disk 9 passes through The middle rotating shaft is connected to the two ends of the working lifting platform 4, and the outer peripheral surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com