Carousel type sheepskin tearing machine

A carousel and rotating rack technology, which is used in peeling tools, slaughtering accessories, slaughtering and other directions, can solve the problems of inefficient production and processing methods, affecting meat quality, hygiene and safety, and low degree of automation, and achieve stable and reliable peeling and peeling effect. Good, highly automated results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

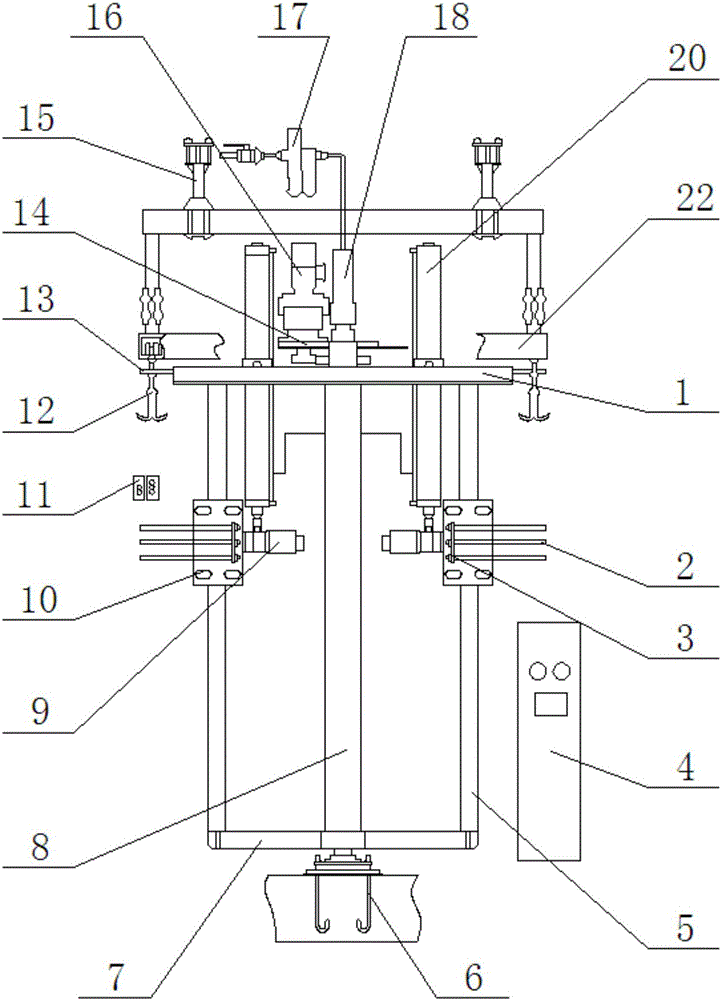

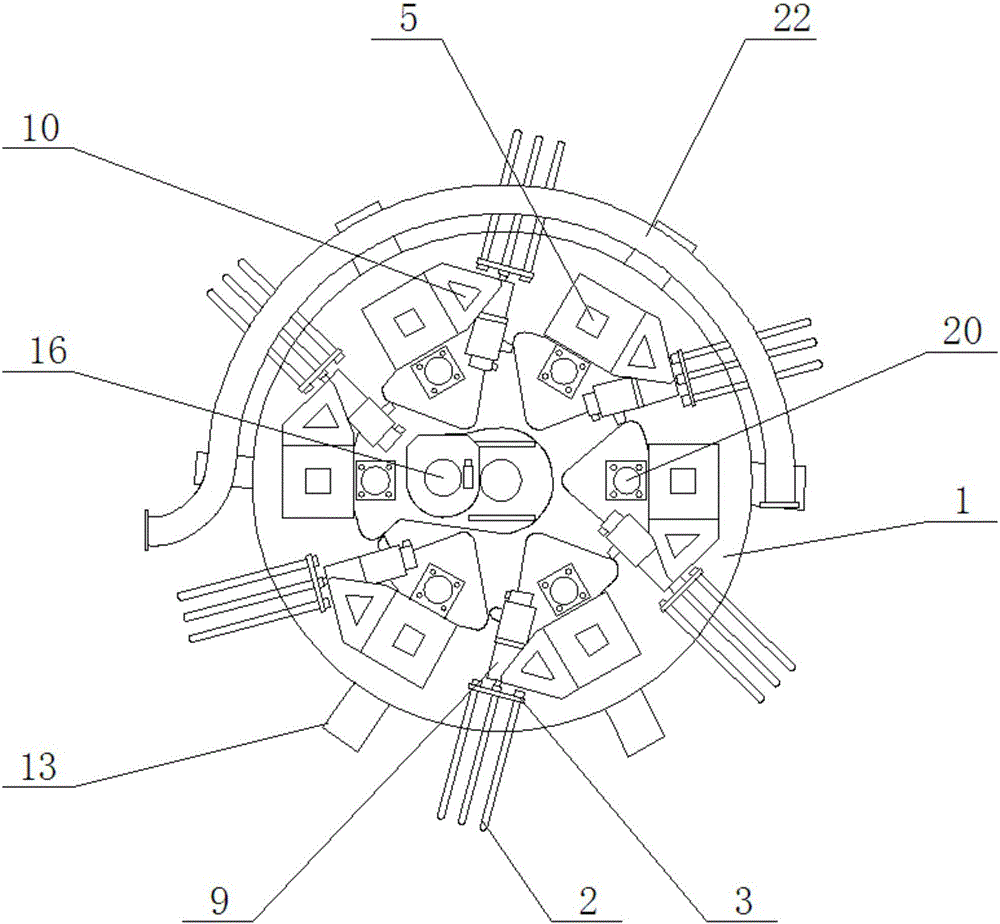

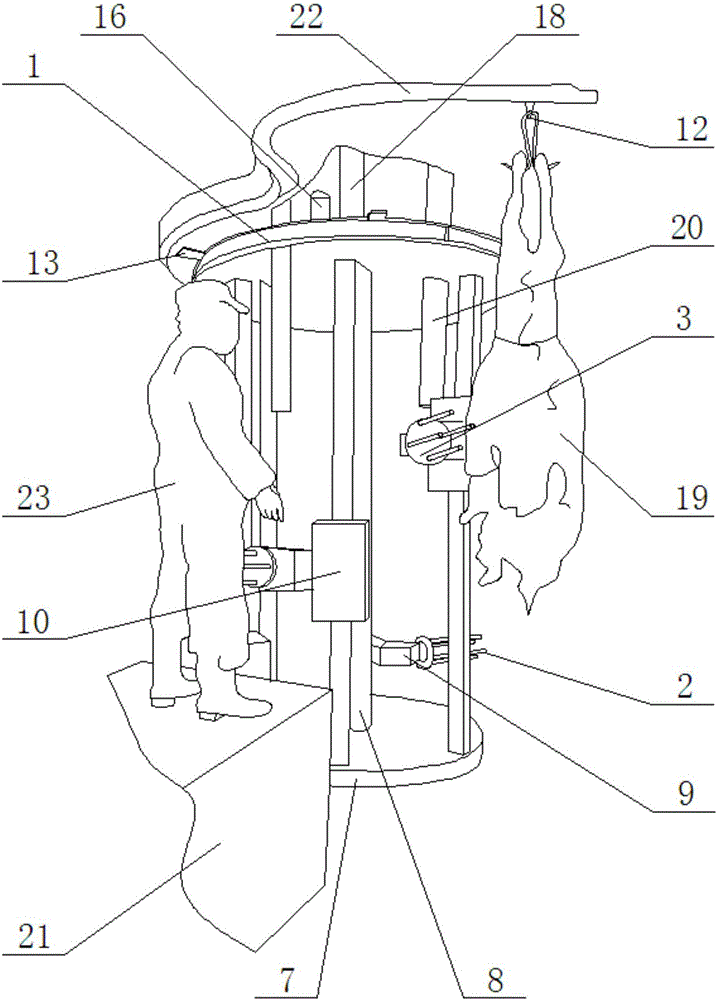

[0026] as attached figure 1 to attach image 3 As shown, a carousel type sheep skinning machine, the sheep skinning machine includes a rotating frame, the top of the rotating frame is fixed by a secondary steel beam 15 in the air, and the bottom of the rotating frame is fixed by anchor bolts buried below the ground 6 is fixed, the overall structure of the rotating frame is a hollowed-out cylindrical structure, and the rotating frame includes an upper disk 1, a lower disk 7 and two guide pillars 5 distributed axisymmetrically, and the guide pillars 5 connect and fix the upper disc 1 and the lower disc 7, wherein the guide post 5 is specifically a stainless steel square tube, and the upper disc 1 and the lower disc 7 are welded by steel plates; each guide post 5 is slidingly connected There is a sliding block 10, and a servo motor 9 is fixed on one side of the sliding block 10. The rotor of the servo motor 9 is connected with a wrapping mechanism 3, and the wrapping mechanism 3...

Embodiment 2

[0031] as attached figure 1 to attach image 3 As shown, a carousel type sheep skinning machine, the sheep skinning machine includes a rotating frame, the top of the rotating frame is fixed by a secondary steel beam 15 in the air, and the bottom of the rotating frame is fixed by anchor bolts buried below the ground 6 fixed, the overall structure of the rotating frame is a hollowed-out cylindrical structure, the rotating frame includes an upper disc 1, a lower disc 7 and six evenly distributed guide posts 5, and the guide posts 5 are connected and fixed The upper disc 1 and the lower disc 7, wherein the guide post 5 is specifically a stainless steel square tube, and the upper disc 1 and the lower disc 7 are welded by steel plates; each guide post 5 is slidably connected with a sliding block 10. A servo motor 9 is fixed on one side of the sliding block 10, and the rotor of the servo motor 9 is connected with a roll-up mechanism 3. The roll-up mechanism 3 includes a chassis on w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com