Preparation method for dried sea buckthorn fruit

A technology for dried sea buckthorn and sea buckthorn, which is applied to the preservation of fruits and vegetables, heating and preservation of fruits/vegetables, food preservation, etc., can solve the problems of high labor intensity, different products of dried sea buckthorn, and low equipment efficiency, so as to improve the overall quality and commodity properties. Good, good sealing condition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The variety of seabuckthorn is late autumn red

[0030] The first stage: The temperature of the coal-fired apricot hot-air drying room is set to 40-50°C, and the treatment time is 3 hours. The main purpose of this stage is to make the internal and external temperatures of the fresh seabuckthorn fruits the same to prepare for the subsequent high-temperature drying.

[0031] The second stage: raise the temperature to 59-60°C, and the drying time is 10 hours. This stage is to expel a large amount of water from the seabuckthorn, that is, the dehumidification stage.

[0032] The third stage: lower the temperature to 48°C, adjust the relative humidity of the drying equipment to 50% for 7 hours, and use a fan to adjust the humidity in the drying equipment.

[0033] The fourth stage: lower the temperature to 42°C, dehumidify evenly, and the treatment time is 4 hours.

[0034] Turn off the heating system, turn on the circulation fan, and use the waste heat in the drying room t...

Embodiment 2

[0037] Seabuckthorn variety is Thornless

[0038] The first stage: the temperature of the coal-fired apricot hot-air drying room is set to 40-50°C, and the treatment time is 4 hours.

[0039] The second stage: raise the temperature to 59-60°C, and the drying time is 12 hours.

[0040] The third stage: the temperature is lowered to 48°C, and the relative humidity of the drying equipment is adjusted to 50%, and the time is 8 hours.

[0041] The fourth stage: lower the temperature to 42°C, evenly dehumidify, and the treatment time is 5 hours.

[0042] Turn off the heating system, turn on the circulation fan, and use the waste heat in the drying room to further dry the seabuckthorn for 45 minutes to obtain the dried seabuckthorn fruit.

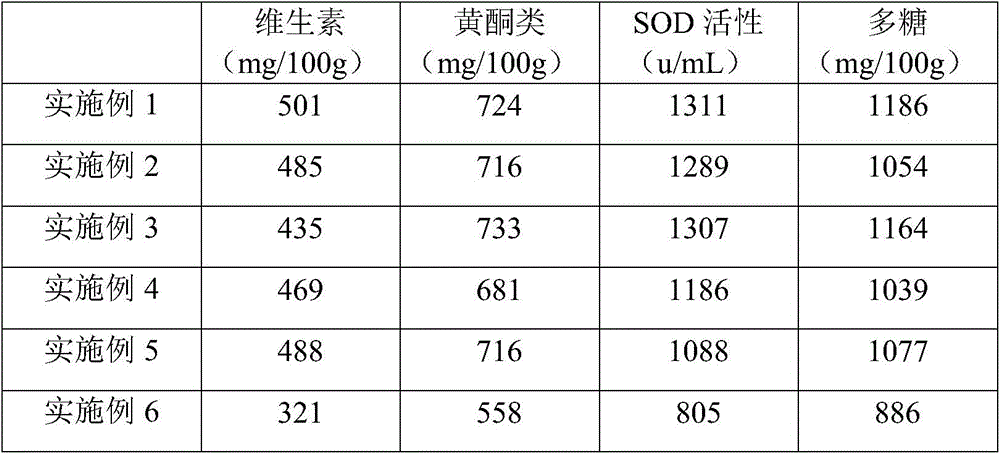

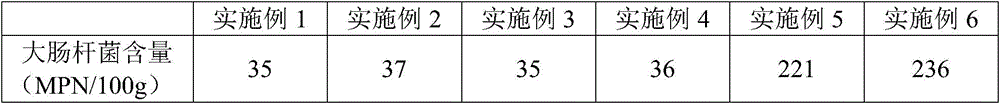

[0043] The quality of the dried seabuckthorn fruit obtained in this example was measured, and the specific results are shown in Table 1. The content of Escherichia coli in the dried seabuckthorn fruit was detected, and the specific results were ...

Embodiment 3

[0045] Seabuckthorn variety is round yellow

[0046] The first stage: the temperature of the coal-fired apricot hot-air drying room is set to 40-50°C, and the treatment time is 5 hours.

[0047] The second stage: raise the temperature to 59-60°C, and the drying time is 13 hours.

[0048] The third stage: the temperature is lowered to 48°C, and the relative humidity of the drying equipment is adjusted to 50%, and the time is 12 hours.

[0049] The fourth stage: lower the temperature to 42°C, evenly dehumidify, and the treatment time is 7 hours.

[0050] Turn off the heating system, turn on the circulation fan, and use the waste heat in the drying room to further dry the seabuckthorn for 45 minutes to obtain the dried seabuckthorn fruit.

[0051] Other processing methods are the same as in Example 1 or slightly adjusted.

[0052]The quality of the dried seabuckthorn fruit obtained in this example was measured, and the specific results are shown in Table 1. The content of Esch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com