Preparation method of vinasse squid

A technology of squid and distiller's grains, which is applied in the field of aquatic product food processing, can solve the problems such as the difficulty of chewing squid shreds or slices, reduce the toughness of squid food, etc., and achieve the effects of soft texture, good chewing, and improved texture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

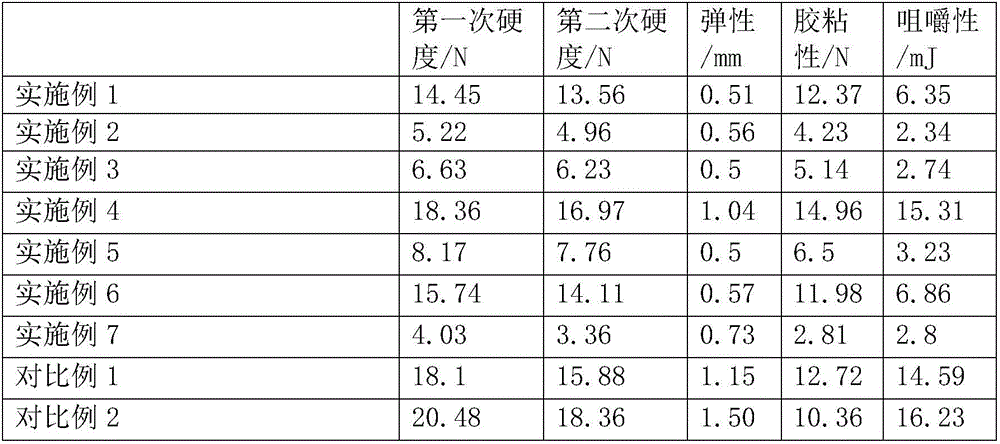

Examples

Embodiment 1

[0021] Production of distiller's lees squid slices:

[0022] 1. Put the chilled squid in tap water, thaw it under running water until the carcass becomes soft, then cut it along the abdominal axis to remove the head, remove the internal organs, soak in hot water at about 50°C for 8-10 minutes, and peel off the skin , cutting squid slices with a length and width of about 5*6cm, washing and draining to obtain the squid raw material to be processed, and then seasoning and marinating.

[0023] 2. Weigh a certain amount of squid slices (about 200g), and add condiments (0.01% spice powder, 0.5-1.5% salt, 0.3-0.8% monosodium glutamate, 0.3-0.8% chicken essence, 0.01% ginger powder) to a clean plate ~ 0.05%, oyster sauce 0.01 ~ 0.1%), mix evenly, and then put it in a refrigerator at 4°C for 24h.

[0024] 3. Take out the squid fillets marinated for 24 hours, move them to a fermenter, add distiller's grains to submerge the samples, tighten the bottle cap, and marinate at room temperatu...

Embodiment 2

[0029] Production of distiller's lees squid slices:

[0030] 1. Put the chilled squid in tap water, thaw it under running water until the carcass becomes soft, then cut it along the abdominal axis to remove the head, remove the internal organs, soak in hot water at about 50°C for 8-10 minutes, and peel off the skin , cutting squid slices with a length and width of about 5*6cm, washing and draining to obtain the squid raw material to be processed, and then seasoning and marinating.

[0031] 2. Weigh a certain amount of squid slices (about 200g), and add condiments (0.01% spice powder, 0.5-1.5% salt, 0.3-0.8% monosodium glutamate, 0.3-0.8% chicken essence, 0.01% ginger powder) to a clean plate ~ 0.05%, oyster sauce 0.01 ~ 0.1%), mix evenly, and then put it in a refrigerator at 4°C for 24h.

[0032] 3. Take out the squid fillets marinated for 24 hours, move them to a fermenter, add distiller’s grains to submerge the samples, tighten the bottle cap, and marinate at room temperatu...

Embodiment 3

[0037] Production of distiller's lees squid slices:

[0038] 1. Put the chilled squid in tap water, thaw it under running water until the carcass becomes soft, then cut it along the abdominal axis to remove the head, remove the internal organs, soak in hot water at about 50°C for 8-10 minutes, and peel off the skin , cutting squid slices with a length and width of about 5*6cm, washing and draining to obtain the squid raw material to be processed, and then seasoning and marinating.

[0039] 2. Weigh a certain amount of squid slices (about 200g), and add condiments (0.01% spice powder, 0.5-1.5% salt, 0.3-0.8% monosodium glutamate, 0.3-0.8% chicken essence, 0.01% ginger powder) to a clean plate ~ 0.05%, oyster sauce 0.01 ~ 0.1%), mix evenly, and then put it in a refrigerator at 4°C for 24h.

[0040] 3. Take out the squid fillets marinated for 24 hours, move them to a fermenter, add distiller's grains to submerge the samples, tighten the bottle cap, and marinate at room temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com