Wax-sealed spherical shell

A spherical shell and wax sealing technology, applied in the directions of sealing, packaging item types, special packaging items, etc., can solve the problems of easy brittle cracking, the contents cannot be effectively sealed and protected, hinder the infiltration of wax liquid, etc., and achieve high sealing degree. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

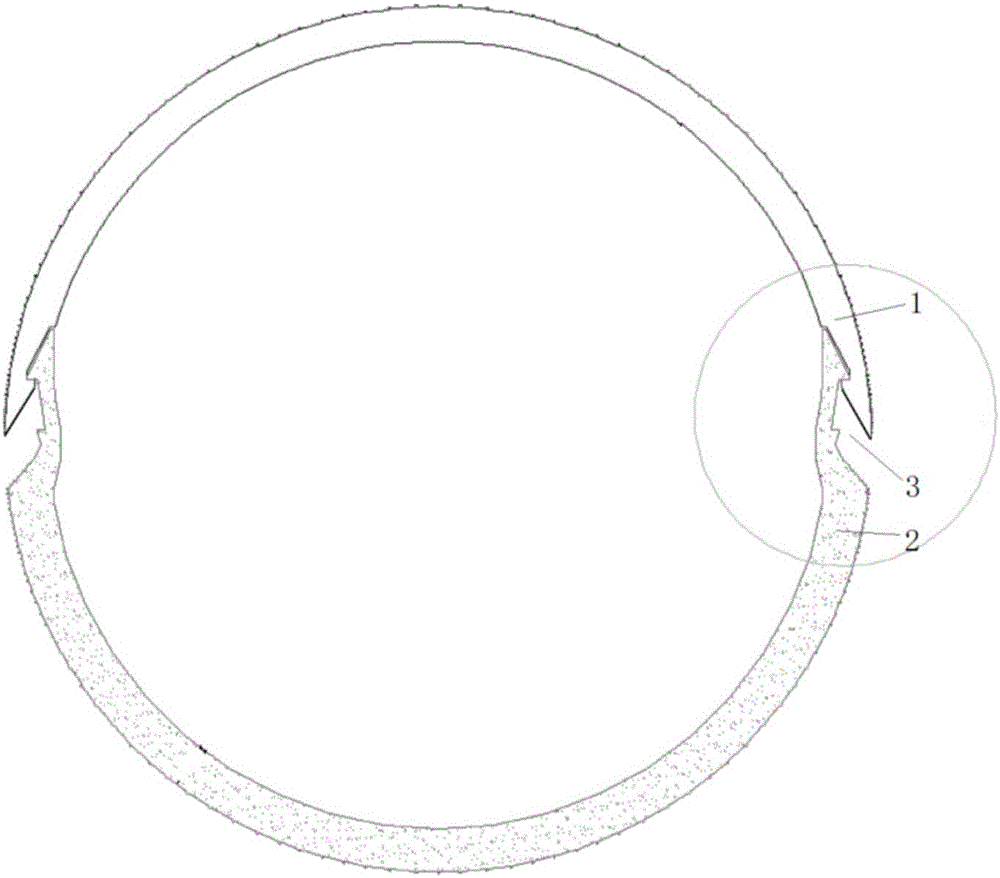

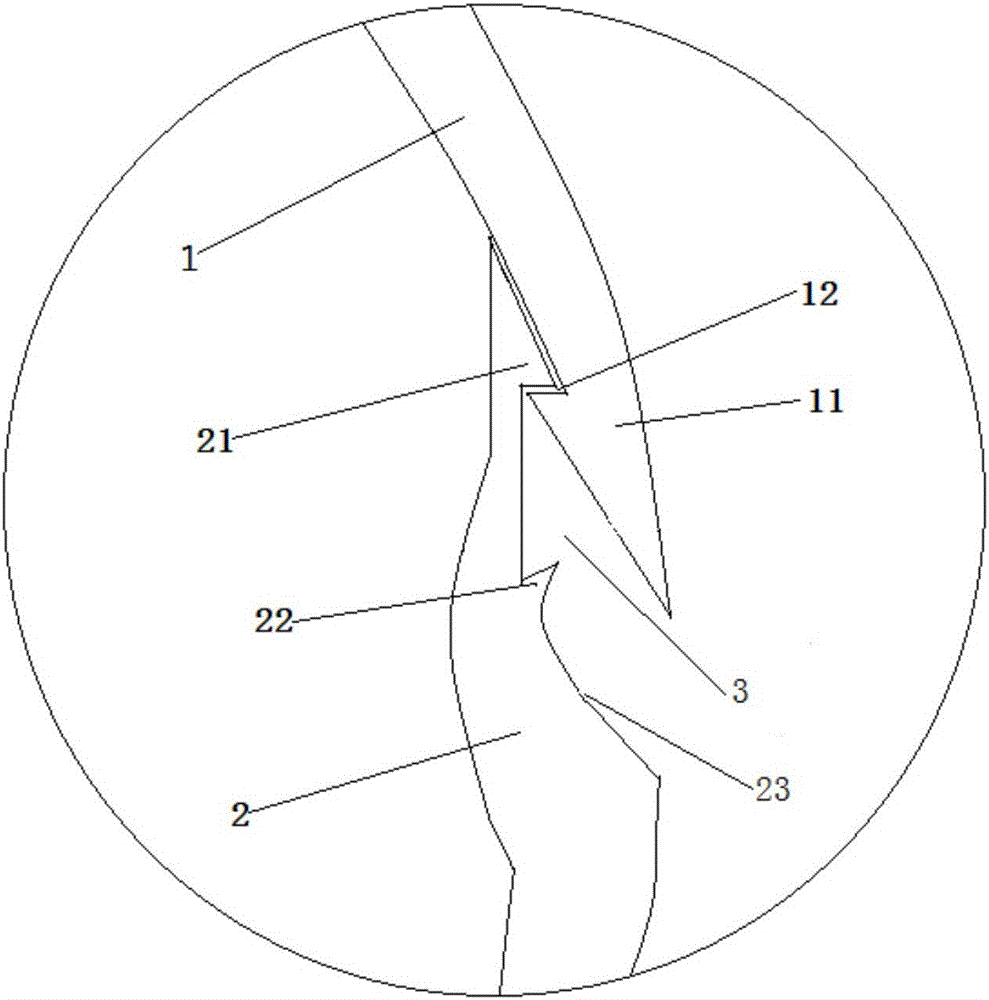

[0032] Such as figure 1 , figure 2 A wax-sealed spherical shell as shown is characterized in that the buckle tongue of the bottom shell 2 is a wedge-shaped buckle round edge 21, the neck of the buckle tongue has a ring flange 22, and the shoulder of the buckle tongue cuts out a ring Body slant 23; the face shell 1 has a tongue-shaped round edge 11, and the body of the face shell 1 and the tongue-shaped round edge 11 form a ring body limit groove 12 that matches the wedge-shaped fastening round edge 21; the face shell 1 After fastening with the bottom shell 2, the flange 22 of the ring body, the bevel 23 of the ring body are not in contact with any point of the tongue-shaped round edge 11, thus forming an open oblique cut-in whole body ring groove 3 at the fastening place of the spherical shell.

Embodiment 2

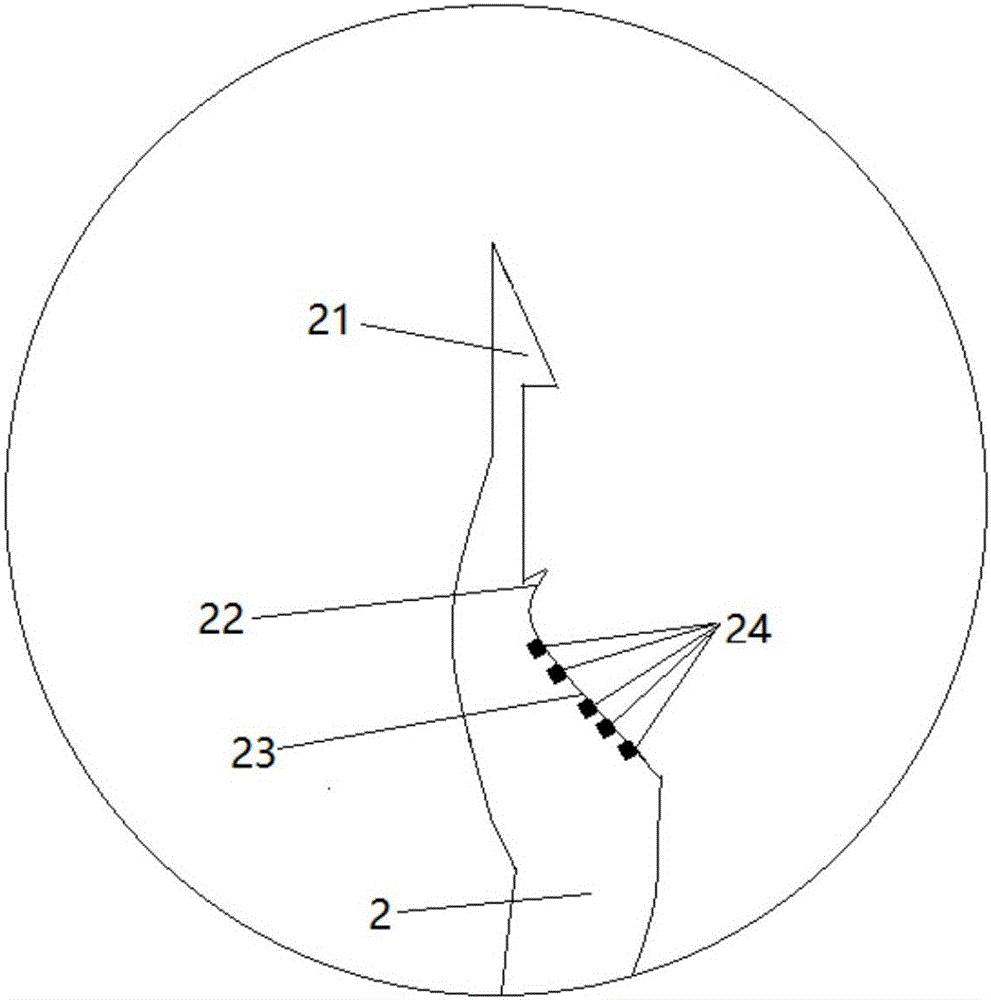

[0034] Such as image 3 The wax-sealed spherical shell shown is based on the first embodiment, and a groove line 24 is provided on the bevel 23 of the ring body.

[0035] These groove lines 24 are parallel to the opening surface of the bottom case 2, and the line type can be designed to be continuous, such as Figure 4 Shown; Groove line 24 can also be designed to be discontinuous, as Figure 5 shown.

Embodiment 3

[0037] Such as Image 6 The wax-sealed spherical shell shown is based on the first embodiment, and a protruding line 25 is provided on the bevel 23 of the ring body.

[0038] These protruding lines 25 are parallel to the opening surface of the bottom case 2, and the line type can be designed to be continuous, such as Figure 7 Shown; Groove line 24 can also be designed to be discontinuous, as Figure 8 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com