Water-based high-aluminous zinc-base alloy paint multipurpose combined drying equipment

A high-aluminum zinc-based, drying equipment technology, applied in the direction of coating, device for coating liquid on the surface, surface pretreatment, etc., can solve the problem of unfavorable classification, management and maintenance of equipment with the same function, and unfavorable centralized supply of energy supply points. , loose and messy layout, etc., to achieve the effect of being conducive to centralized energy supply, convenient equipment maintenance and management, and less site area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific drawings and embodiments.

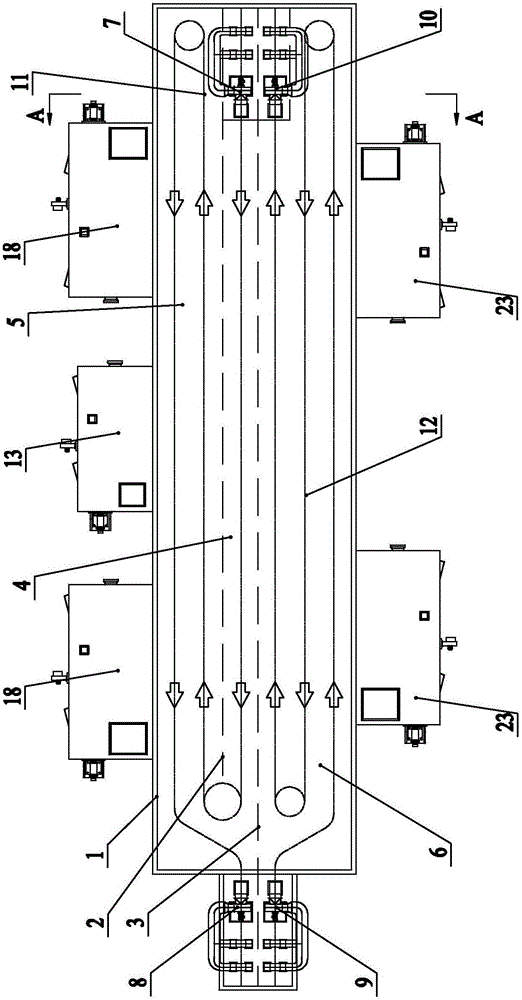

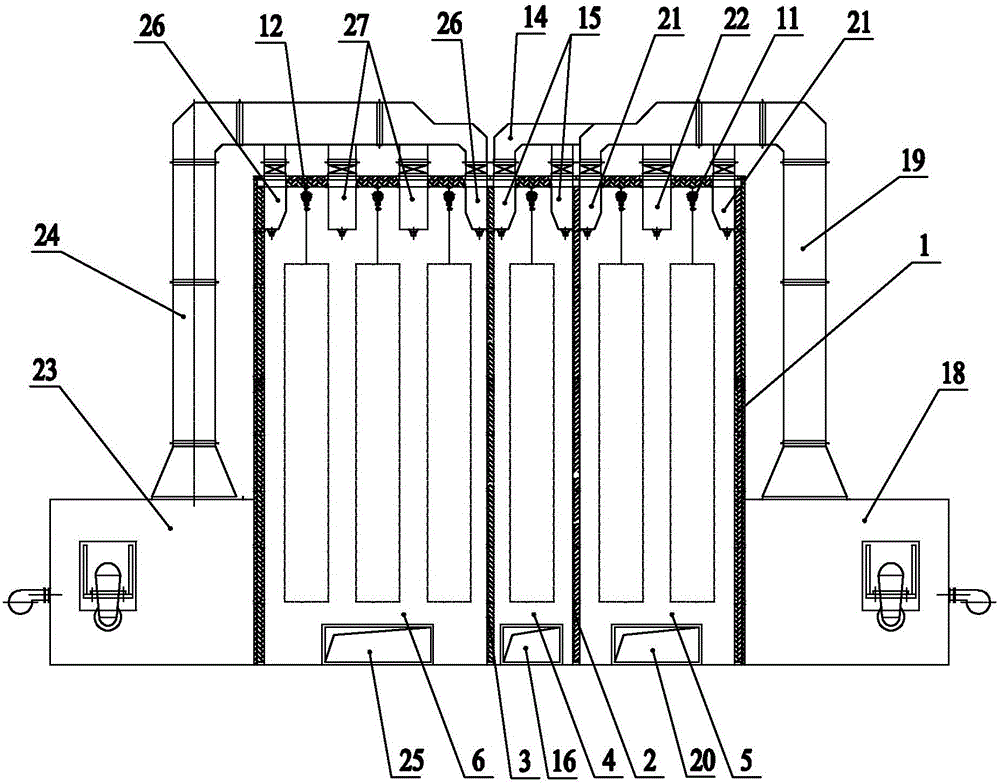

[0021] As shown in the figure: the water-based high-aluminum-zinc-based alloy coating multi-purpose combined drying equipment in the embodiment mainly includes a long chamber body 1, and the inner space of the long chamber body 1 passes through the first partition 2 and the second partition 3 is divided into a pre-drying area 4, a drying area 5 and a curing area 6 parallel to each other. The pre-drying area 4 communicates with the pre-drying hot air circulation system, and the drying area 5 communicates with the drying hot air circulation system. The curing area 6 is connected with the curing hot air circulation system; the pre-drying area 4 is located between the drying area 5 and the curing area 6, the left end of the pre-drying area 4 is connected with the left end of the drying area 5, and the pre-drying area 4 is connected with the curing area 6 The right ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com