Formulating method of slab continuous casting machine foundation roller gap technology

A slab continuous casting machine and basic technology, applied in the field of steelmaking and continuous casting, can solve problems such as single roll gap and unclear formulation principles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

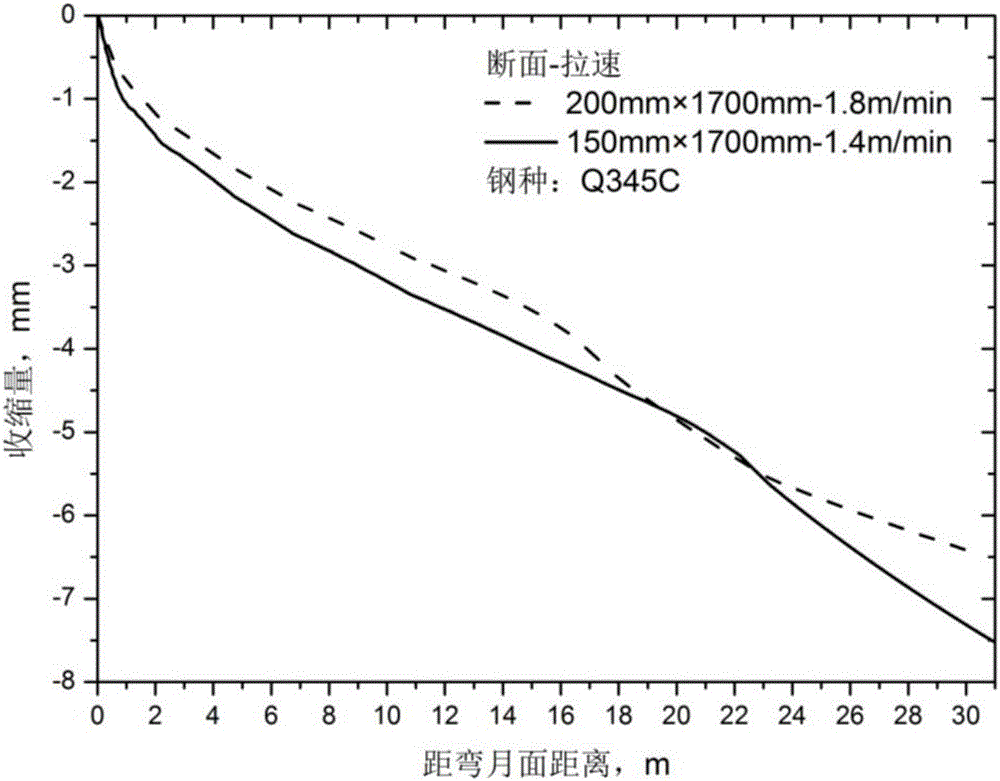

[0044] The basic roll gap technology of the slab continuous casting process with a section of 150mm×1700mm and 200mm×1700mm was calculated respectively, and the corresponding casting speeds were 1.8m / min and 1.4m / min respectively. Table 1 shows the parameters and technology of the relevant casting machine equipment parameter.

[0045] Table 1 continuous casting process parameters

[0046]

[0047] The specific steps and parameters are as follows:

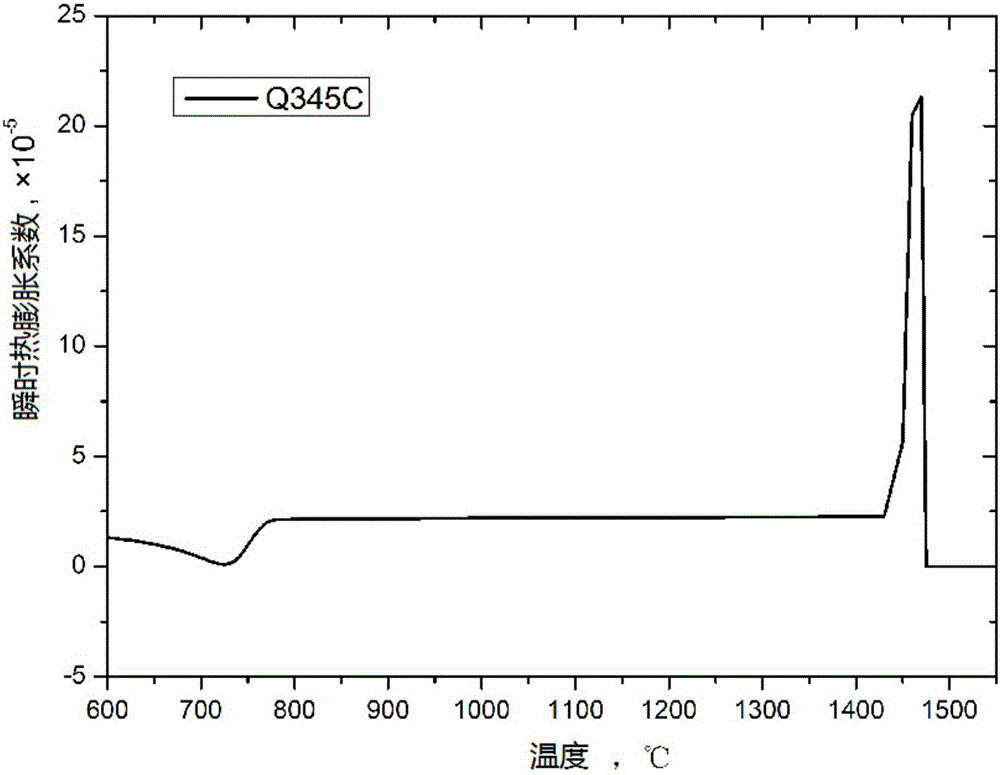

[0048] 1. The calculated steel type is Q345C, and its instantaneous thermal expansion coefficient in the range from room temperature to liquidus can be calculated and measured by commercial software JmatPro. figure 1 It is the relationship between the instantaneous thermal expansion coefficient and temperature of Q345C.

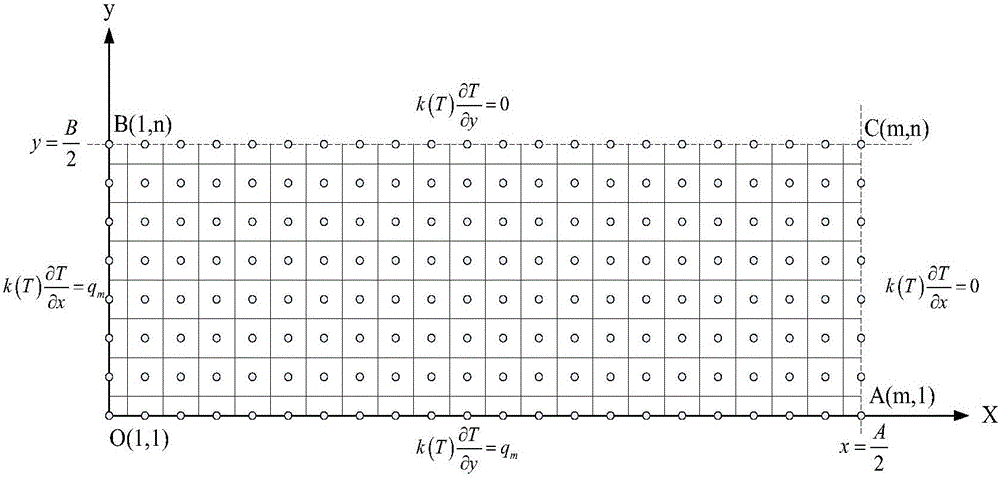

[0049] 2. Solidification heat transfer model calculation: establish a finite element analysis model suitable for a specific slab caster, use a 1 / 4 section as the calculation domain, and develop a subroutine su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com