Self-rotating automatic material receiver

A material catcher and automatic technology, which is applied in metal processing and other directions, can solve the problems of easy flying of the workpiece, unsoft movements, and large swing range, etc., and achieve the effect of small swing range, soft motion, and small space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

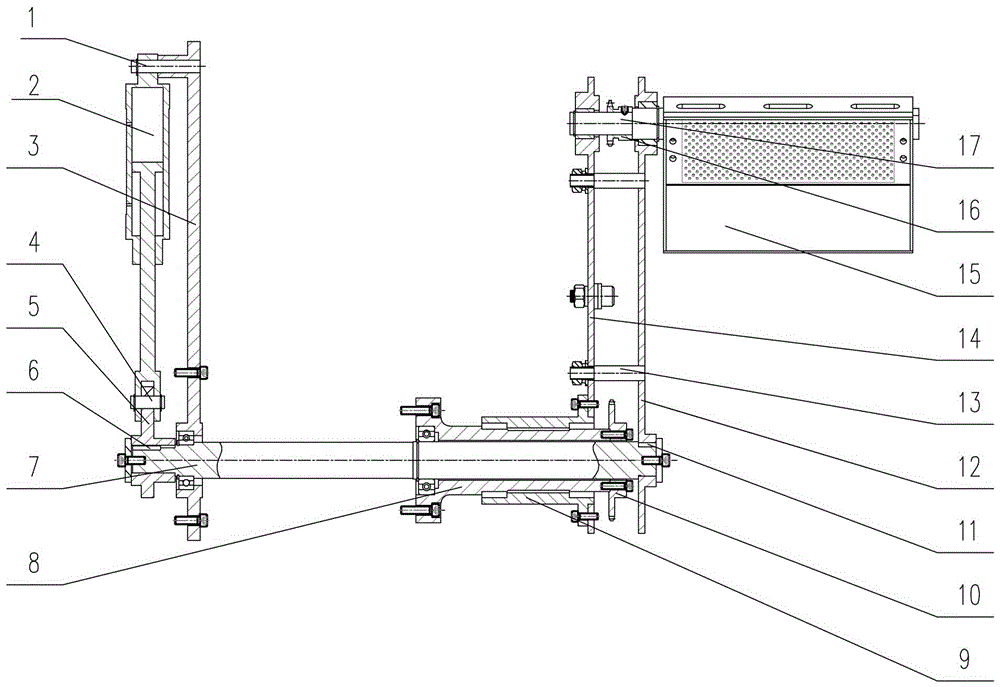

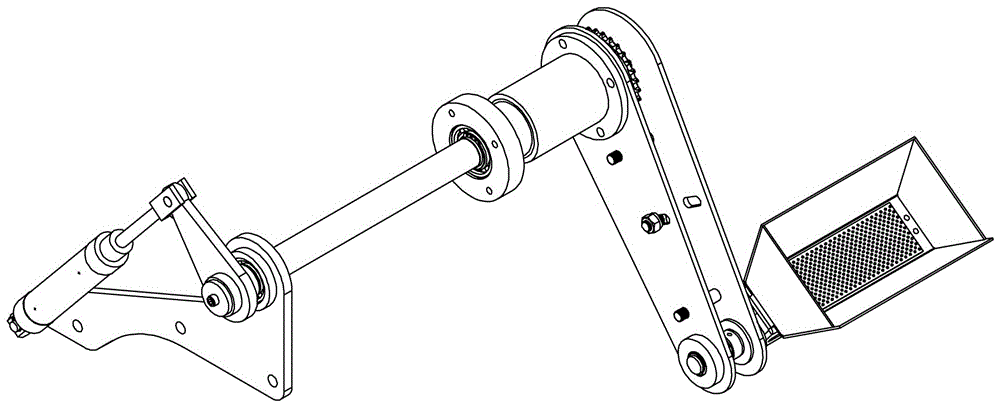

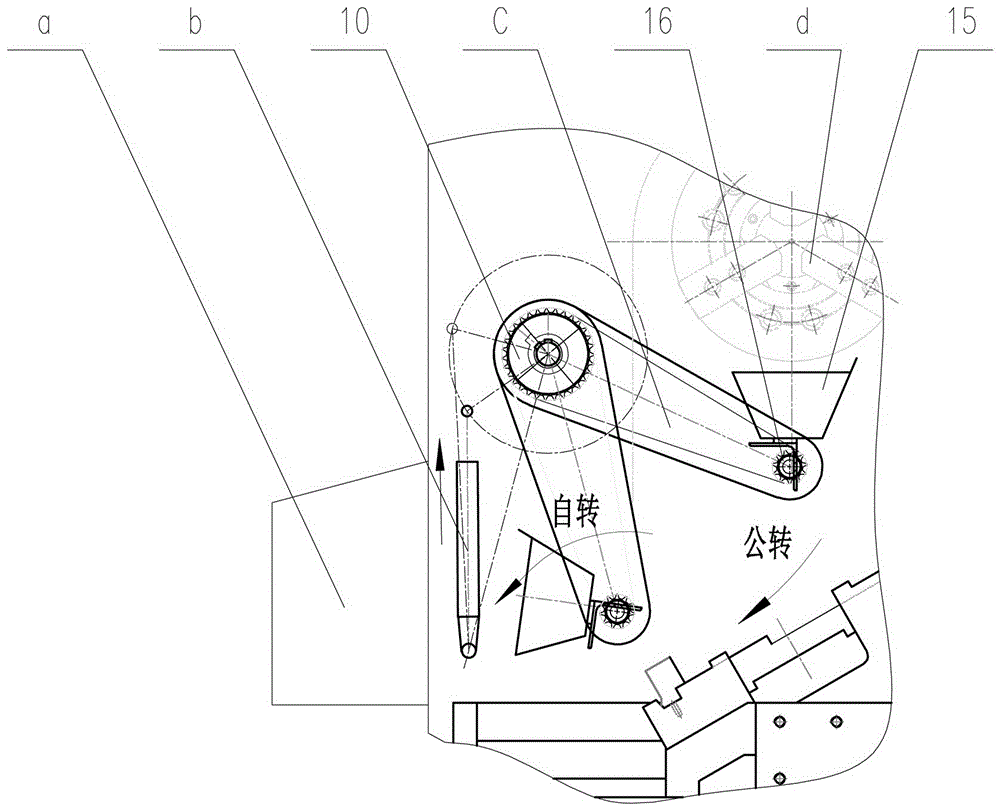

[0027] Such as figure 1 As shown, the support plate 3 and the support sleeve 8 are installed on the side of the bedside box by bolts, and the support plate 3 is equipped with pin shaft I and transmission shaft 7. The base of the rod cylinder 2 rotates on the pin shaft I, and the other end of the rod cylinder 2 is hinged on the driving arm 5 of the transmission shaft 7 . The rod cylinder 2 and the driving arm 5 are connected through the pin shaft 4, and the driving arm 5 and the transmission shaft 7 are connected through the flat key 6. Through the above connection, the reciprocating linear motion of the rod cylinder 2 drives the driving arm 5 into the positive direction of the transmission shaft 7. Anti-rotational movement.

[0028] Wherein, the large sprocket 10 is fixedly installed on the supporting sleeve 8 and is a non-moving part. The swing arm is formed by connecting the front plate 12 and the rear plate 14 through the pin shaft III. The front plate 12 is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com