Automatic wire connecting and welding device for HDMI connection terminal

A connection terminal, automatic technology, used in welding equipment, metal processing equipment, auxiliary devices, etc., can solve problems such as inconvenient operation, affecting product quality, and prone to defective products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

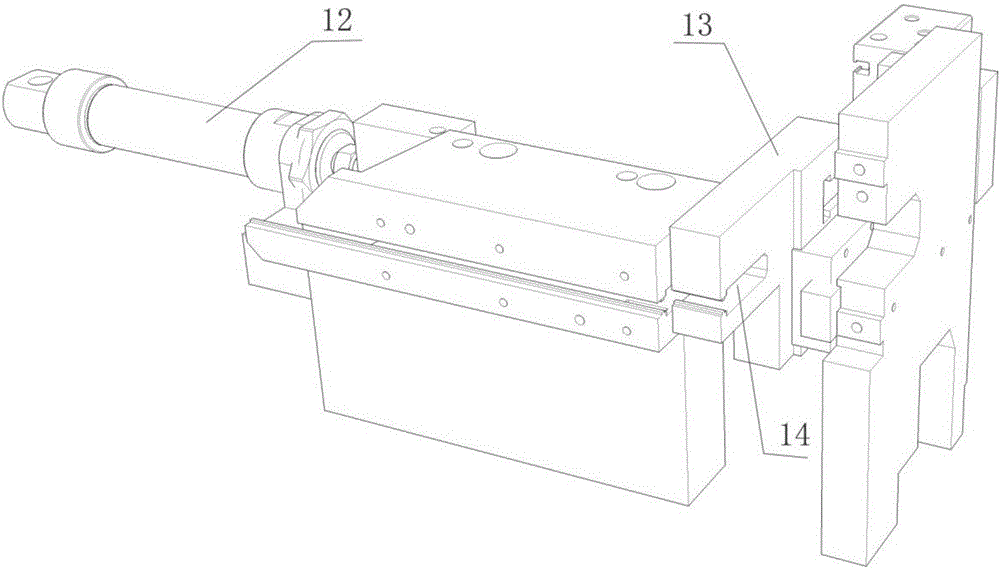

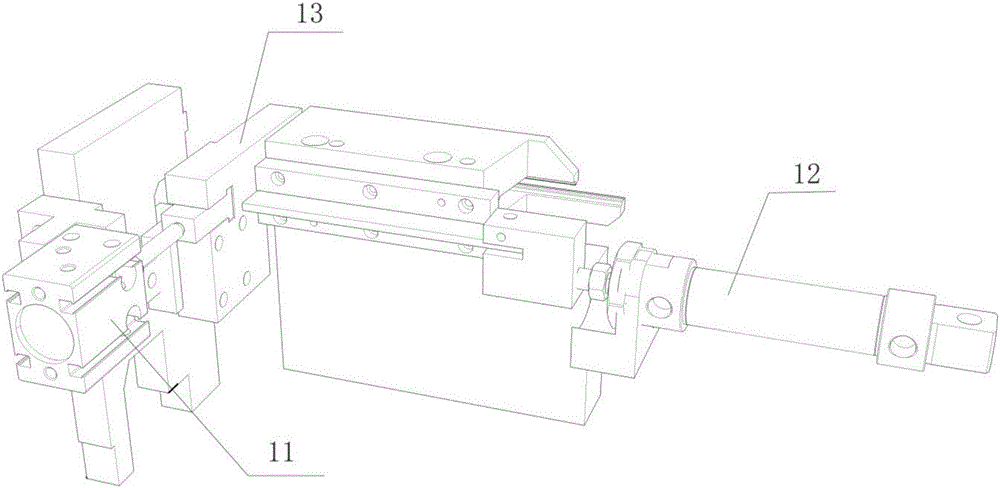

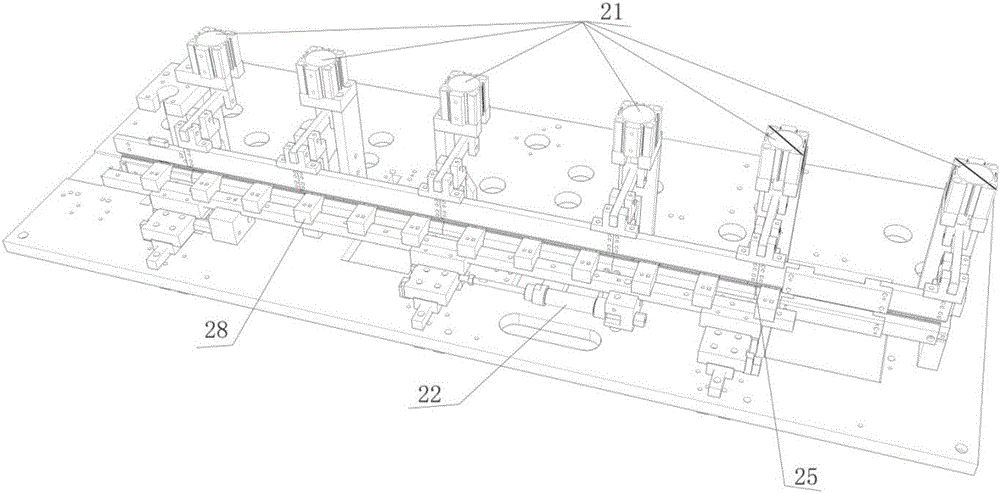

[0041] Reference Figure 1 to Figure 19 , An embodiment of the automatic wire bonding equipment for HDMI connection terminals of the present invention is proposed:

[0042] An automatic wire bonding equipment for HDMI connection terminals, including a translation device set on a working platform for transmitting a fixed wire branch frame 38 and arranged in order from left to right for pushing the branch frame 38 to the translation device The branch line advancement device, the line cutting device used to shorten the length of the line, the first upper and lower line splitting line straightening and stripping of the upper and lower rows of wires on the branch frame 38 Thread skin device, thread scraping and cutting device used to cut the thread again and scrape off the remaining thread skin, used to fix the position ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap