Thermal processing method for improving elongation of heat-treatable aluminum alloy welded joints

A technology of welding joints and thermal processing, which is applied in metal processing equipment, welding equipment, welding/welding/cutting items, etc., can solve the problems of reduced mechanical properties of welded joints, and optimize fracture path, disperse stress, and tensile strength Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] For products with a model thickness of 8mm, the implementation parameters are shown in Table 1:

[0048] Table 1 Welding parameters of products with a thickness of 8mm

[0049]

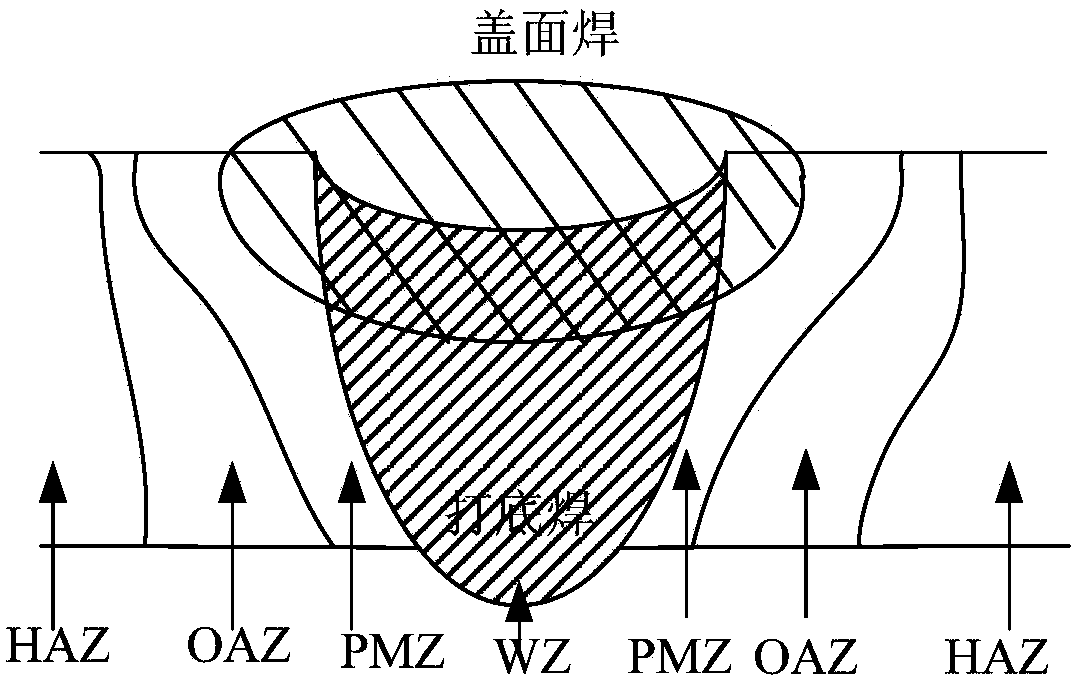

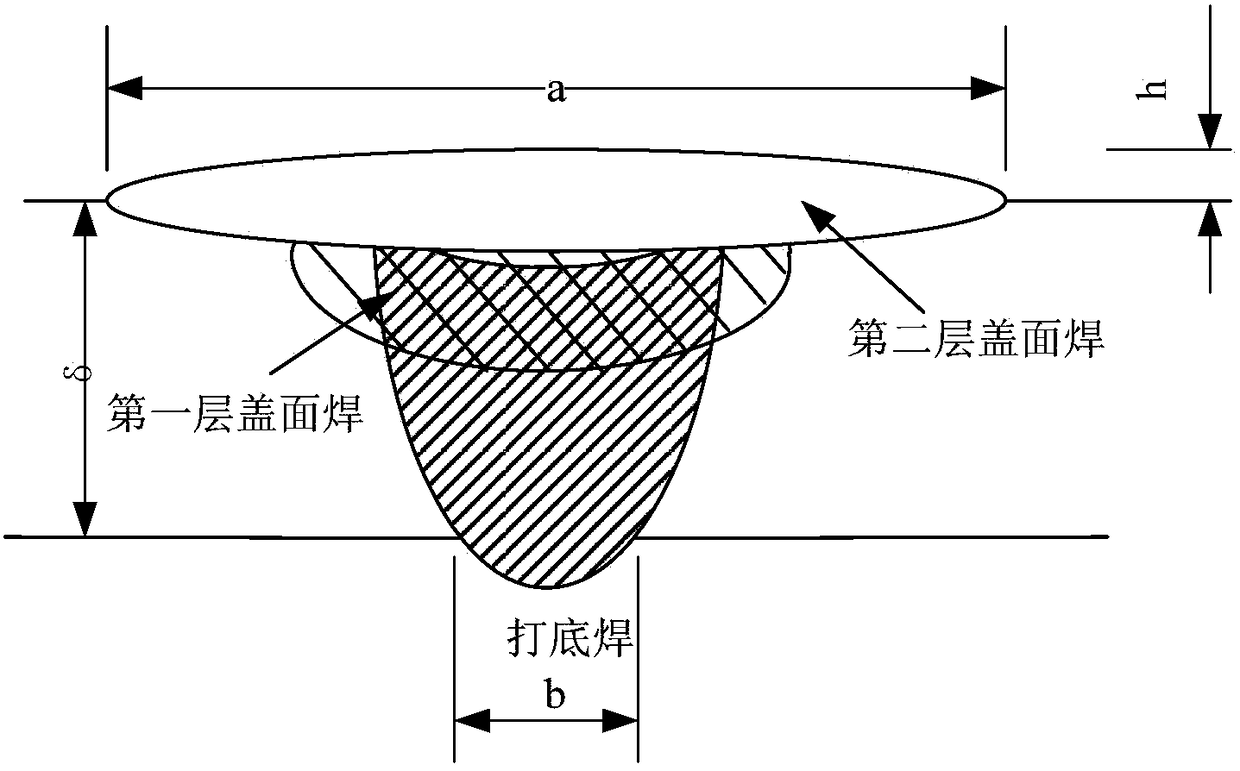

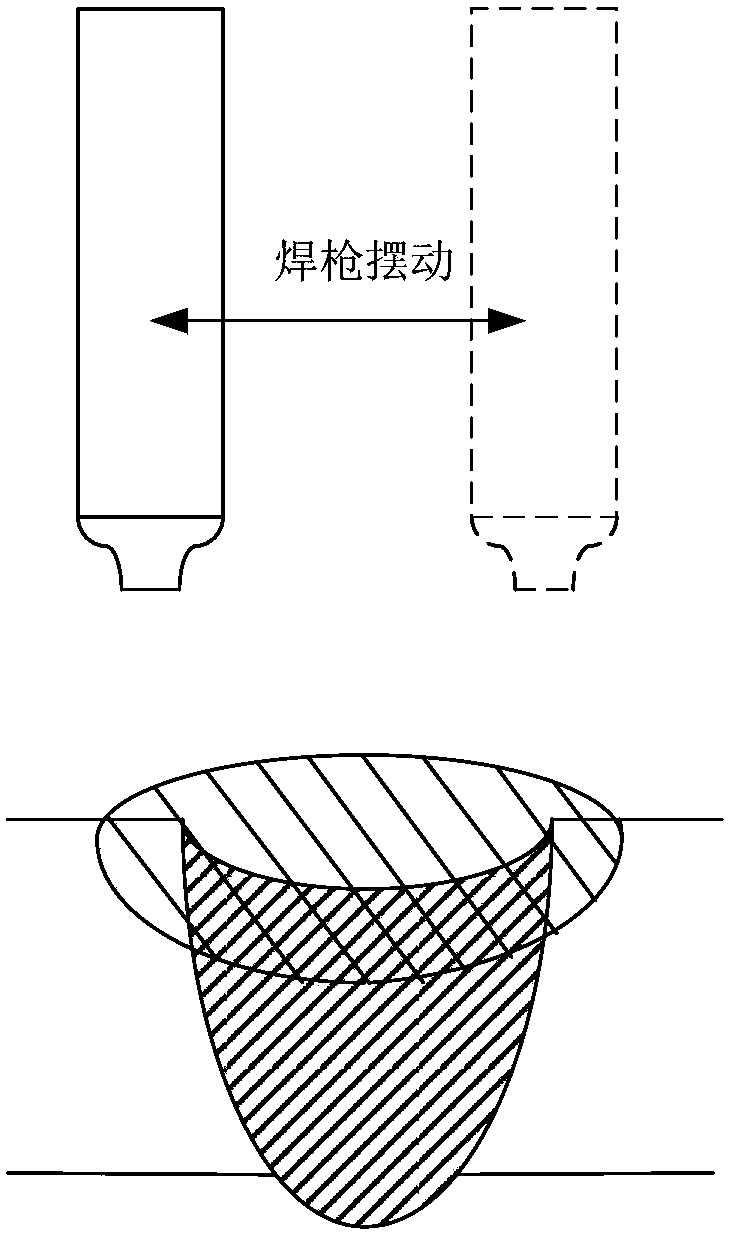

[0050] Wherein, the size parameter of the second layer of cover satisfies a=2δ+b+3mm, h=1.5mm, a is the front width of the second layer of cover, b is the back width of bottom welding, and δ is the thickness of the workpiece to be welded , h is the frontal reinforcement of the second layer of covering, and the unit is mm.

[0051] The elongation of the first layer after welding is 3.5%, and the strength is 280‐290MPa. The elongation rate of the second layer cover after welding is 5.0%, and the strength is 320MPa.

Embodiment 2

[0053] For products with a model thickness of 10mm, the implementation parameters are shown in Table 2:

[0054] Table 2 Welding parameters of products with a thickness of 10mm

[0055]

[0056] Wherein, the size parameter of the second layer of cover satisfies a=2δ+b‐3mm, h=2mm, a is the front width of the second layer of cover, b is the back width of the bottom welding, δ is the thickness of the workpiece to be welded, h is the frontal reinforcement of the second layer of covering, in mm.

[0057] The elongation of the first layer after welding is 3.5%, and the strength is 280‐295MPa. The elongation rate of the second layer cover after welding is 5.5%, and the strength is 310MPa.

Embodiment 3

[0059]For products with a model thickness of 12mm, the implementation parameters are shown in Table 3:

[0060] Table 3 Welding parameters of products with a thickness of 12mm

[0061]

[0062] Wherein, the size parameter of the second layer of cover satisfies a=2δ+b+2mm, h=1.8mm, a is the front width of the second layer of cover, b is the back width of bottom welding, and δ is the thickness of the workpiece to be welded , h is the frontal reinforcement of the second layer of covering, and the unit is mm.

[0063] The elongation of the first layer after welding is 3.0%, and the strength is 290‐300MPa. The elongation rate of the second layer cover after welding is 5.5%, and the strength is 330MPa.

[0064] It can be seen from the above three embodiments that according to the method of the present invention, the mechanical properties of the joint of the workpiece to be welded are significantly improved, the tensile strength is increased from 280-300MPa to 310-330MPa, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com