Device for automatically feeding and pressing two end sockets of boneless scraper blade

An automatic piercing and bone scraping technology, which is applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of spring deformation, finger wear and tear, and easy deformation of scraping blades.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The specific implementation, features and functions of a device for automatically piercing both ends of a boneless scraper according to the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

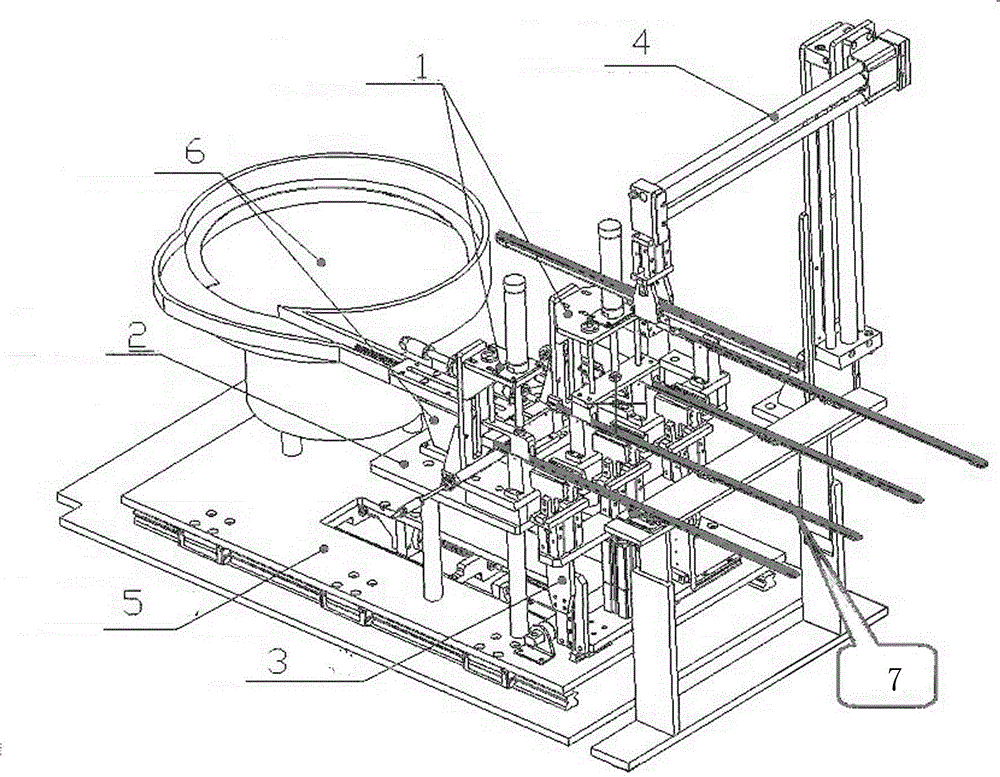

[0048] see Figure 1-2 And the diagram of each part, a device that automatically presses both ends of the boneless scraper. It has a left-right symmetrical structure. The product return mechanism 4, the left and right servo adjustment mechanism 5 and the vibration feeding mechanism 6 are composed. The automatic equipment has four stations, and the four stations are: the first station-the discharging station, the second station- Automatically feed the end and press it into place, the third station-test the pull-off force of the end, the fourth station-recompression and reclaiming station;

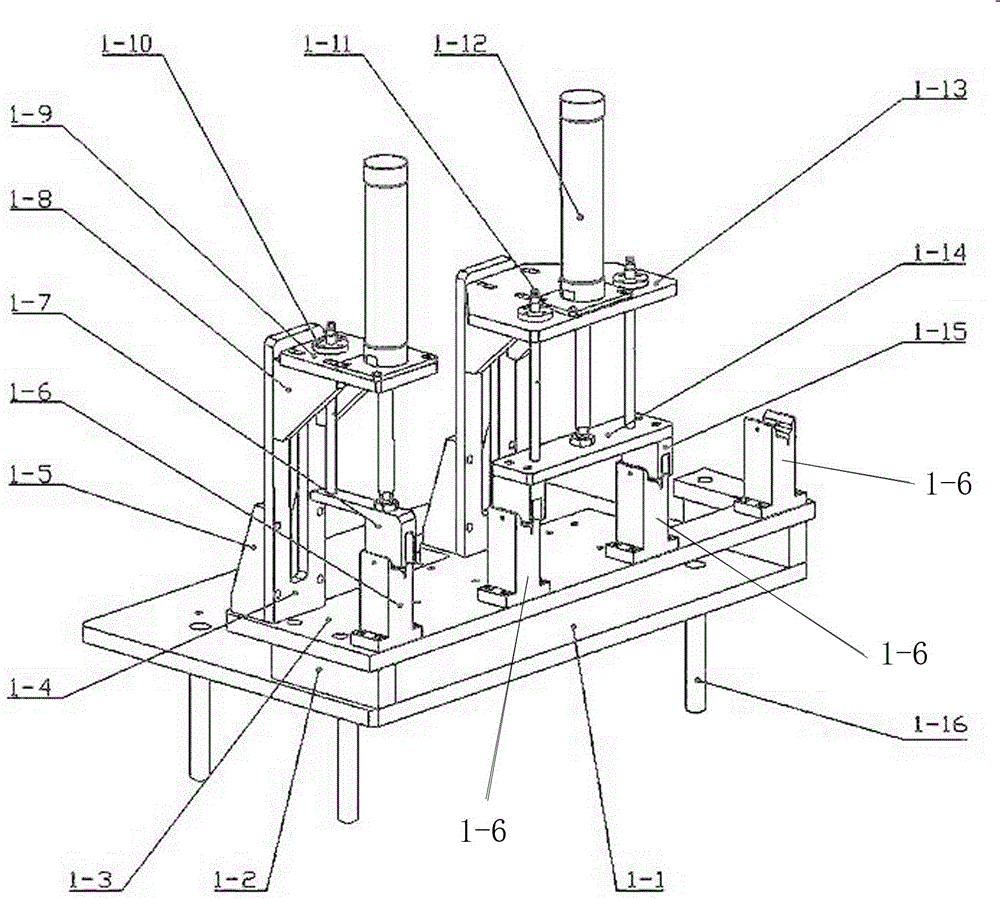

[0049] The flat scraper direct pressing mechanism 1 includes a straightening mechanism bottom plate 1-1, which is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com