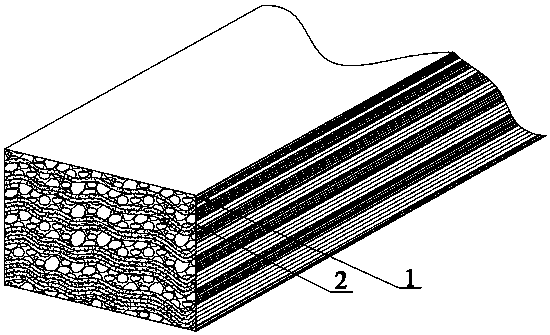

A kind of recombined bamboo-wood composite decorative veneer and its manufacturing method

A technology of bamboo-wood composite and manufacturing method, which is applied to the jointing of wooden veneers, manufacturing tools, and wood layered products, etc., which can solve the problems of high density of bamboo-based fiber composite materials and complicated planing process, and achieve streamlined production process, alleviate the tension of timber resources, and reduce the effect of production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

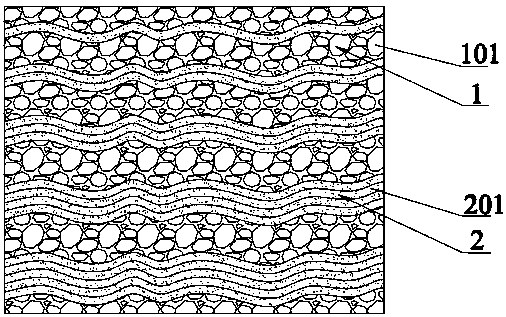

[0028] Example 1: A manufacturing method of recombined bamboo-wood composite decorative veneer

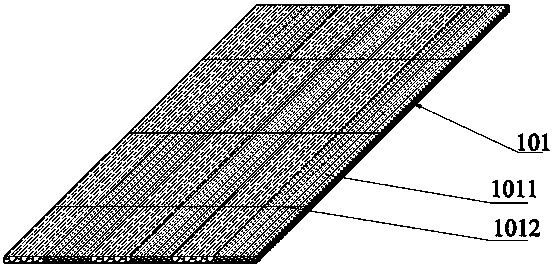

[0029] 1) The 4-year-old Moso bamboo is divided into bamboo slices with a width of 20 mm, and then processed into 40 mm flexible bamboo bundles 1011 through degreening, yellowing, and dispersing processes. The individual bamboo bundles in the flexible bamboo bundle 1011 are connected to each other without detachment. The width of the root bamboo bundle fiber is 1-3 mm; the veneer 201 is sliced from Eucalyptus eucalyptus as the fast-growing wood veneer 201, and the thickness of the veneer is 0.6 mm.

[0030] 2) The flexible bamboo bundle 1011 is processed into a flexible bamboo bundle curtain 101 with a width of 150mm by weaving, the feed speed is 5m / min during the weaving process, the distance between the braiding lines is 400mm, and the large ends of the bamboo bundles are arranged adjacent to the small ends during the weaving process; The flexible bamboo bundle curtain 101 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com