Reactive powder concrete delayed coagulation adjustable constant feeding control method and device

A technology of quantitative feeding device and active powder, which is applied in clay preparation device, unloading device, cement mixing device, etc. The effect of smooth material and delayed initial setting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

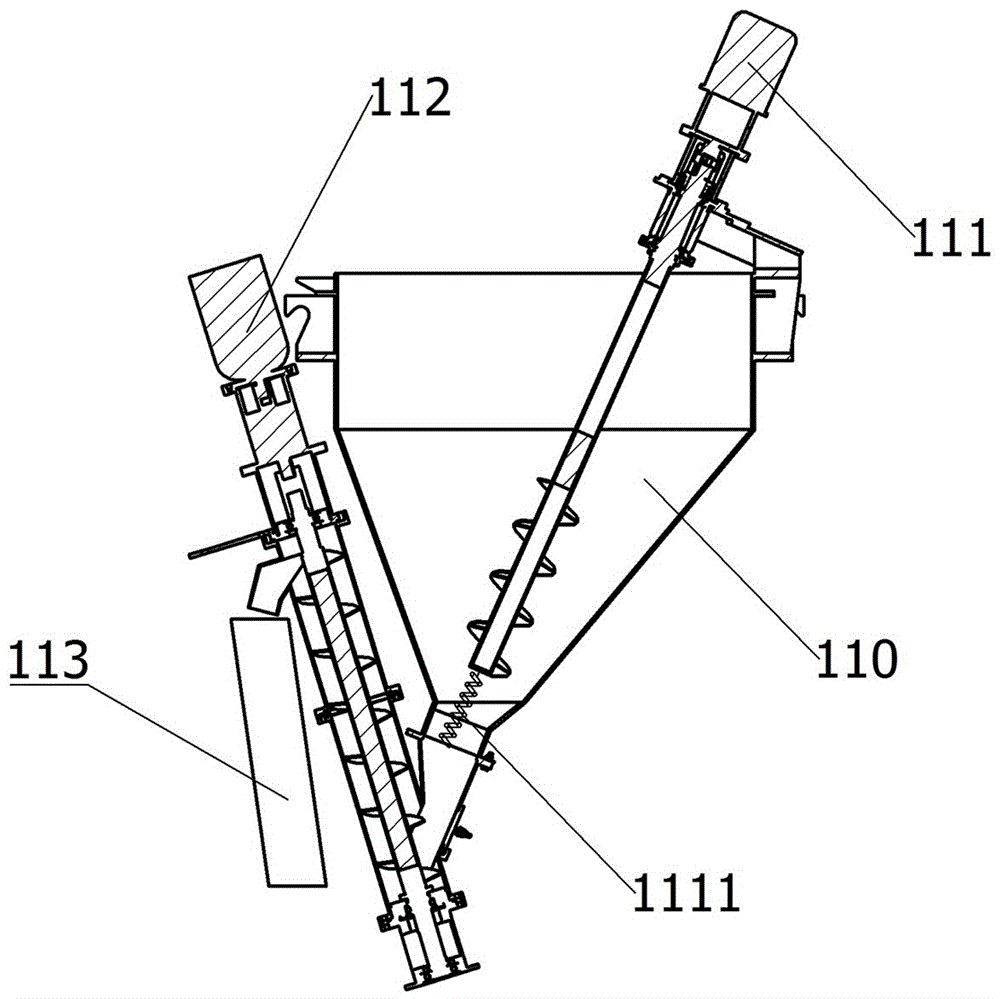

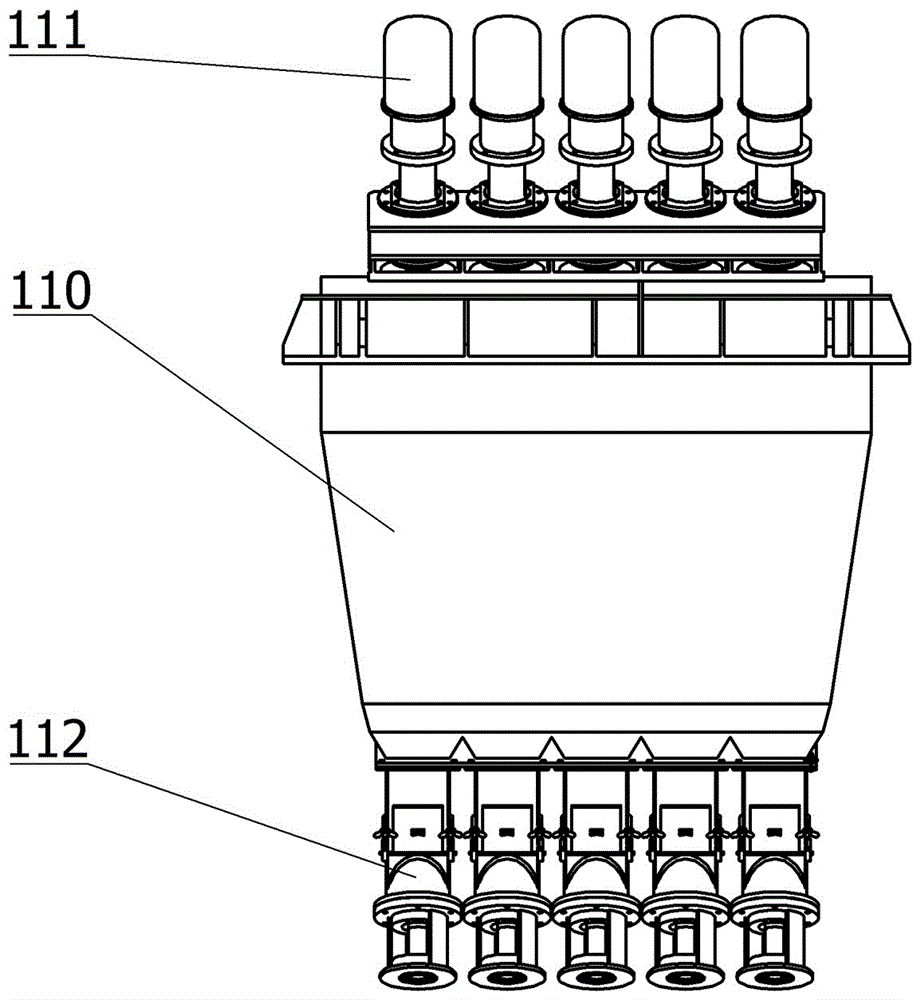

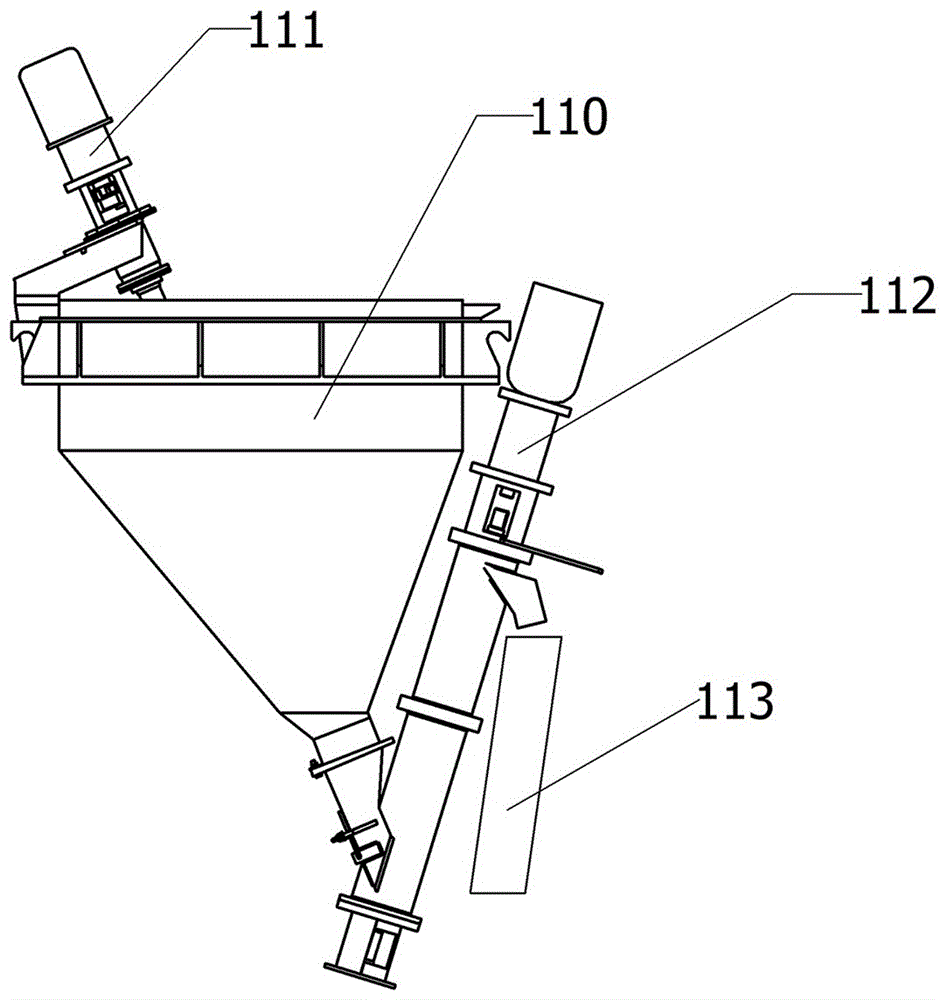

[0025] Embodiment 1, the present invention comprises hopper 110, anti-sudden agitation device 111, adjustable-speed screw discharger 112 and directional chute 113; The discharge port provided is connected to the feed port provided at the lower part of the speed-adjustable discharge machine 112, the anti-sudden agitation device 111 is installed on the upper part of the trough 110, and the lower part of the anti-sudden agitation device 111 extends into the inner cavity of the trough 110. The discharge port provided on the upper waist of the speed-adjustable discharge machine 112 is matched with the directional chute 113 and connected. refer to Figure 1 to Figure 4 .

[0026] In the present invention, the anti-sudden-setting stirring device 111 is repeatedly rotated in the inner cavity of the trough 110 to destroy the quick-setting characteristics of the active powder concrete, so that the active powder concrete will not be quick-set, and at the same time, it can also ensure th...

Embodiment 2

[0027] Embodiment 2, the present invention can also be provided with more than 2 outlets at the lower part of the trough 110, and an anti-sudden agitation device 111 and an adjustable-speed spiral discharge outlet are respectively arranged on the chute 110 corresponding to each outlet. Machine 112, the lower end of the anti-sudden-condensation stirring device 111 and the lower part of the speed-adjustable screw discharger 112 are respectively matched with the corresponding discharge ports. The control of quantitative feeding can be realized by controlling the rotating speed of the adjustable speed discharging machine 112, or controlling the number of adjustable speed discharging machines 112; The number of jobs is used to realize the control of quantitative feeding. refer to Figure 1 to Figure 4 , all the other are with embodiment 1.

Embodiment 3

[0028] Embodiment 3, the present invention also can also be provided with spring 1111 at the end of anti-sudden-condensation stirring device 111, and one end of spring 1111 is suspended on the free end of anti-sudden-condensation stirring device 111, and the other end of spring 1111 stretches into the outlet of feed tank 110. Inside the feed port. When the motor drives the spring 1111 installed at the end of the anti-sudden agitation device 111 to rotate, the spring 1111 is driven to rotate, thereby destroying the rapid setting characteristics of the active powder concrete in the discharge port, ensuring that the discharge port of the hopper is not blocked, and effectively preventing the active powder concrete from sudden After coagulation, the outlet is blocked and the distribution system fails. refer to Figure 1 to Figure 4 , and the rest are the same as the combination of any one of the above embodiments or two embodiments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com