Automatic press-fitting and bonding equipment for large-diameter round top cover inner side lining and using method

A round top cover and inner side technology, which is applied in the field of automatic press-fitting and bonding equipment for the inner side lining of large-diameter round top covers, can solve problems such as low work efficiency, cumbersome operation, and insufficient adhesion. Achieve the effects of simplifying the pressing process, ensuring the quality of pressing and ensuring the bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

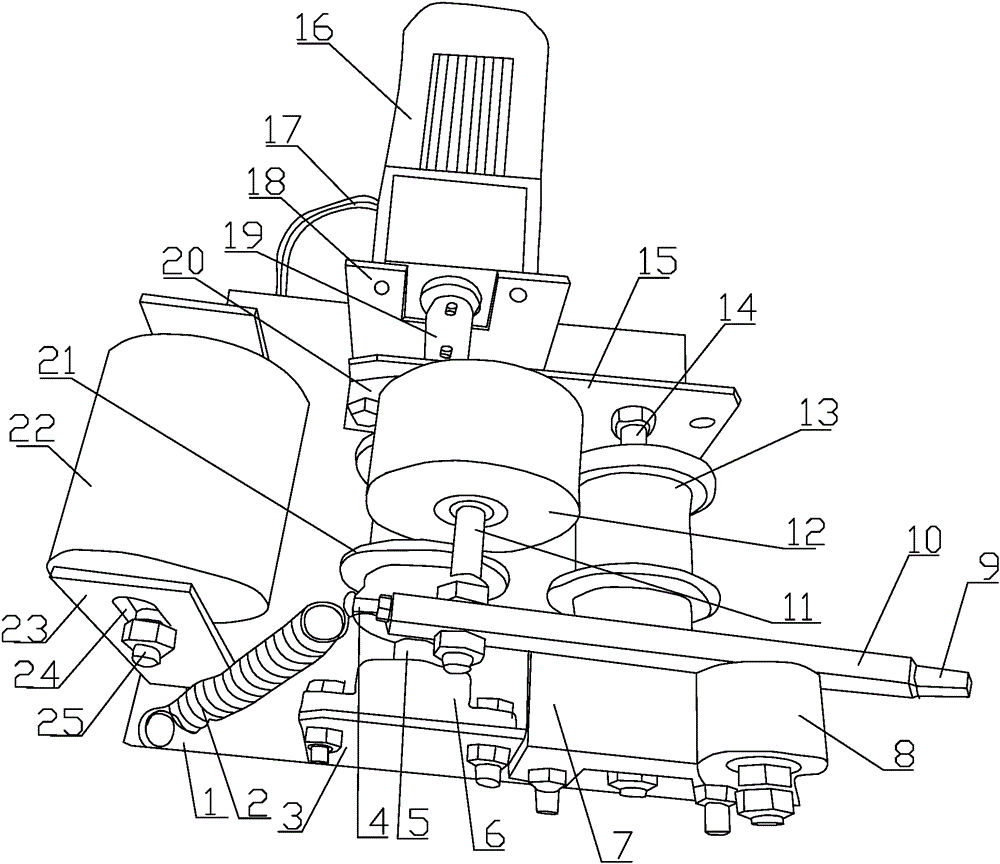

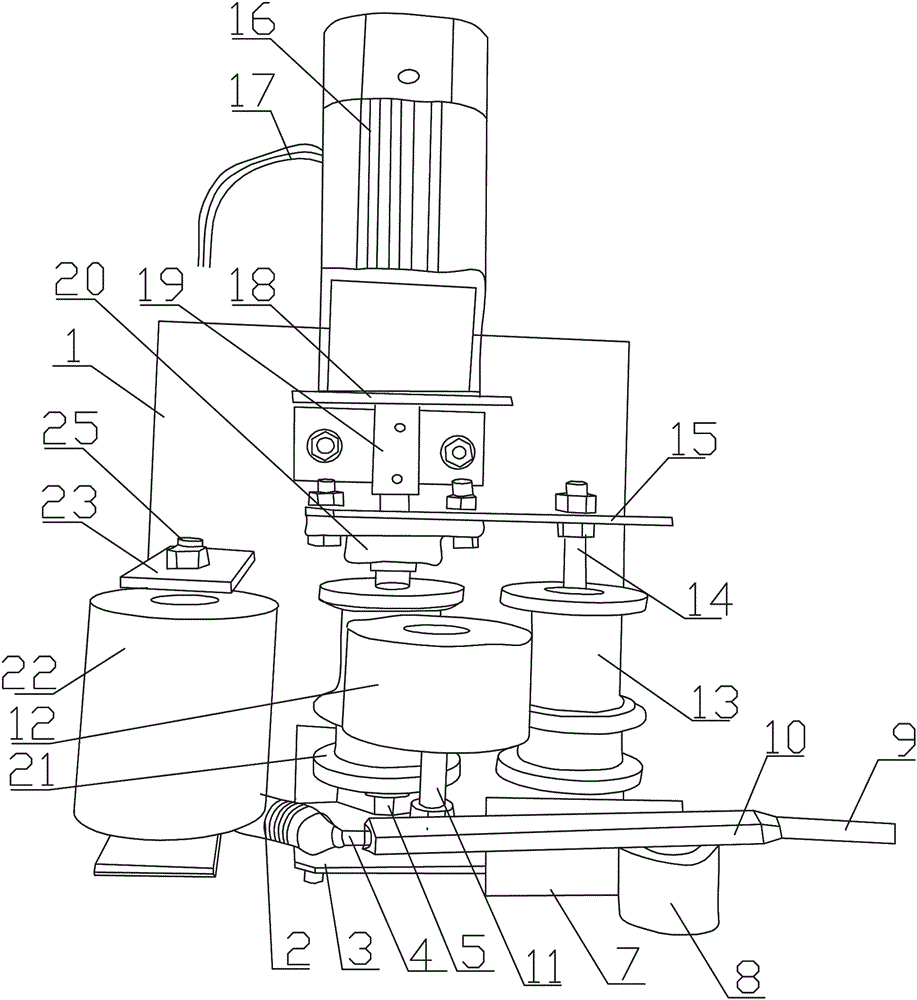

[0046] join Figure 1-6 , a large-diameter circular roof inner side lining automatic press-fit bonding equipment, it includes a base plate 1, the top surface of the base plate 1 is equipped with a No. 1 auxiliary pressure roller device, and the No. 1 auxiliary pressure roller device is installed On the two No. 1 support plates 23, the bottom of the No. 1 support plate 23 is fixedly installed on the base plate 1; the No. 2 auxiliary pressure roller device and the No. 3 auxiliary pressure wheel device are installed on the base plate 1 by the left support plate 3 and the right support plate 15. The No. 1 auxiliary pinch device, the No. 2 auxiliary pinch device and the No. 3 auxiliary pinch device form three lines of support for the outer edge of the top cover; the side of the No. 2 auxiliary pinch device is installed There is a motor drive device, the motor drive device drives the No. 2 auxiliary pinch wheel device and drives the top cover to rotate; the upper top surface of the ...

Embodiment 2

[0058] The method of using press-fit bonding equipment includes the following steps:

[0059] In the first step, at first the inner surface of the edge 2601 of the top cover 26 is coated with glue, and a layer of strip-shaped wrapping paper is preliminarily pasted;

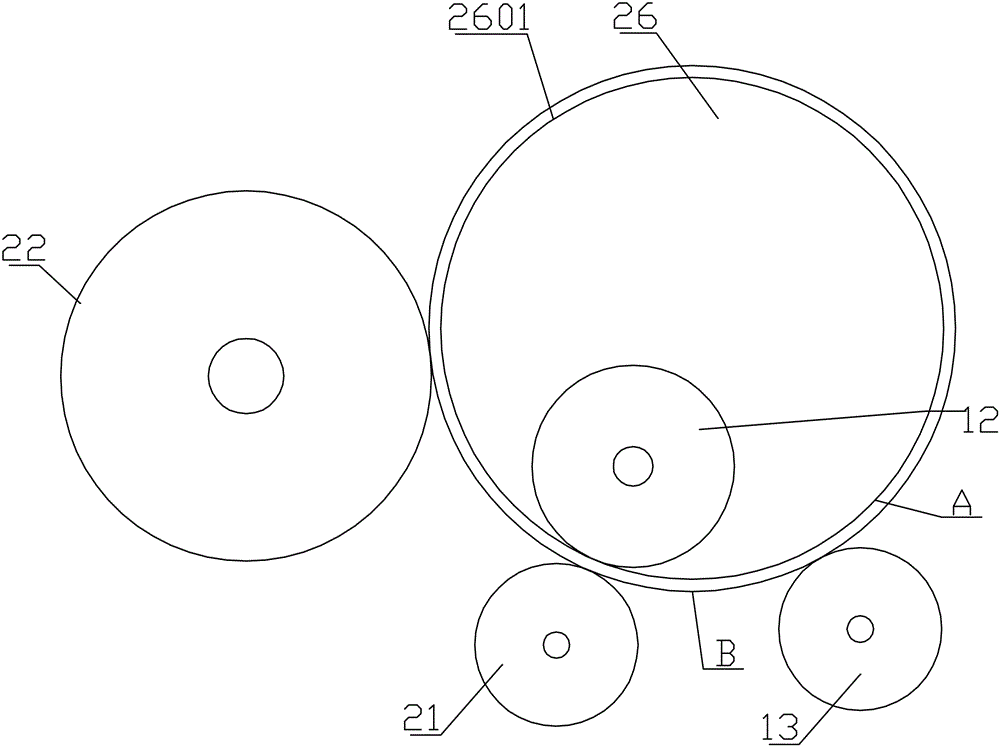

[0060] In the second step, the top cover 26 after the preliminary pasting is installed on the press-fitting and bonding equipment, wherein the outer surface of the edge 2601 is simultaneously connected with the first pressure roller 22, the second pressure roller 21 and the third pressure roller 13. The outer surface B of the top cover 26 is matched with the outer surface B to form three lines of support, and then the pressure roller 12 is matched with the inner surface A of the edge 2601 of the top cover 26;

[0061] In the third step, after the installation of the above-mentioned pressure wheel device and the top cover 26 is completed, the motor 16 is started, and the second pressure wheel 21 is driven by the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com