Hydraulic retarder provided with two end surface thrust plates and double rows of radial plungers

A retarder and distribution plate technology, applied in the direction of brakes, etc., can solve the problems of waste of heat energy consumption, kinetic energy loss, poor heat dissipation capacity, etc., and achieve the effect of strong continuous working ability, high space utilization rate, and recycling and utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings.

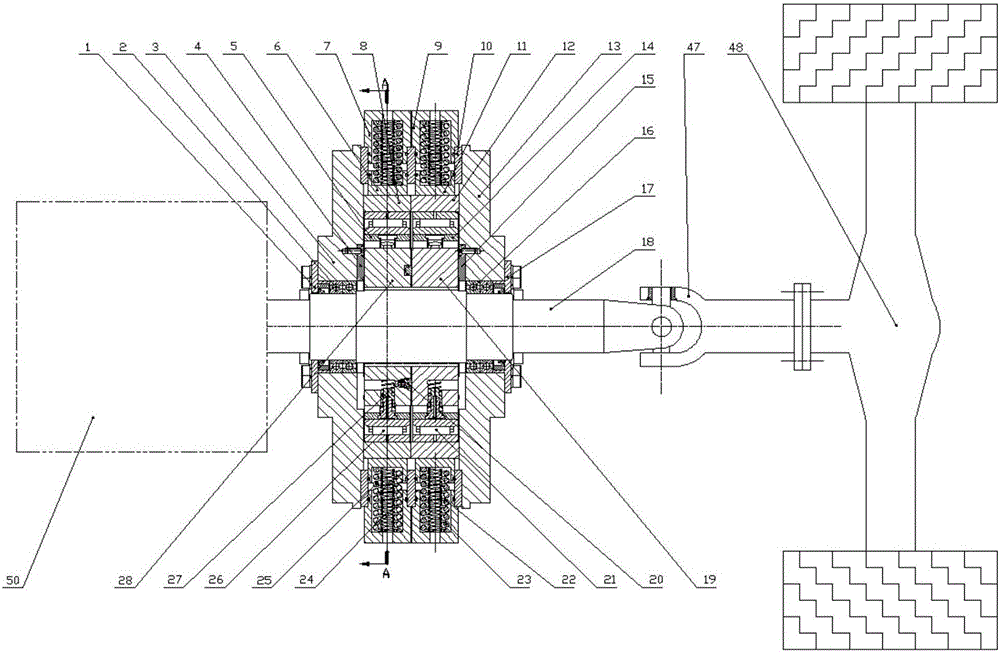

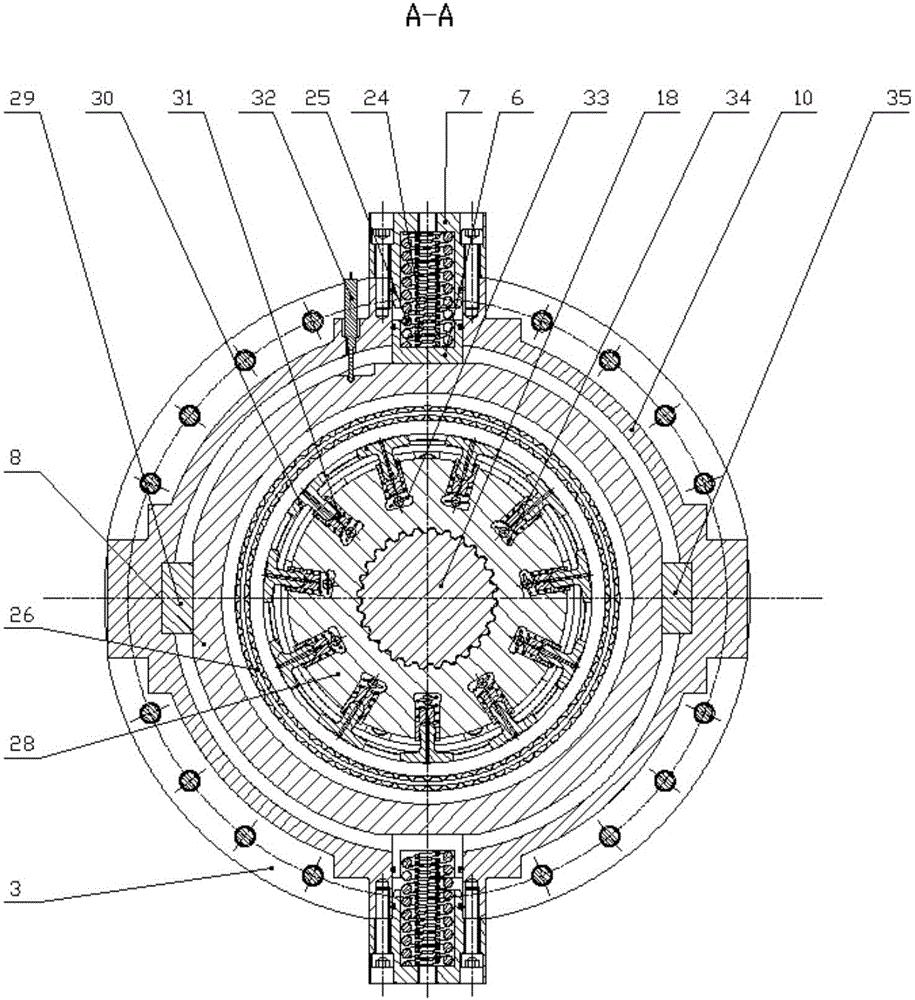

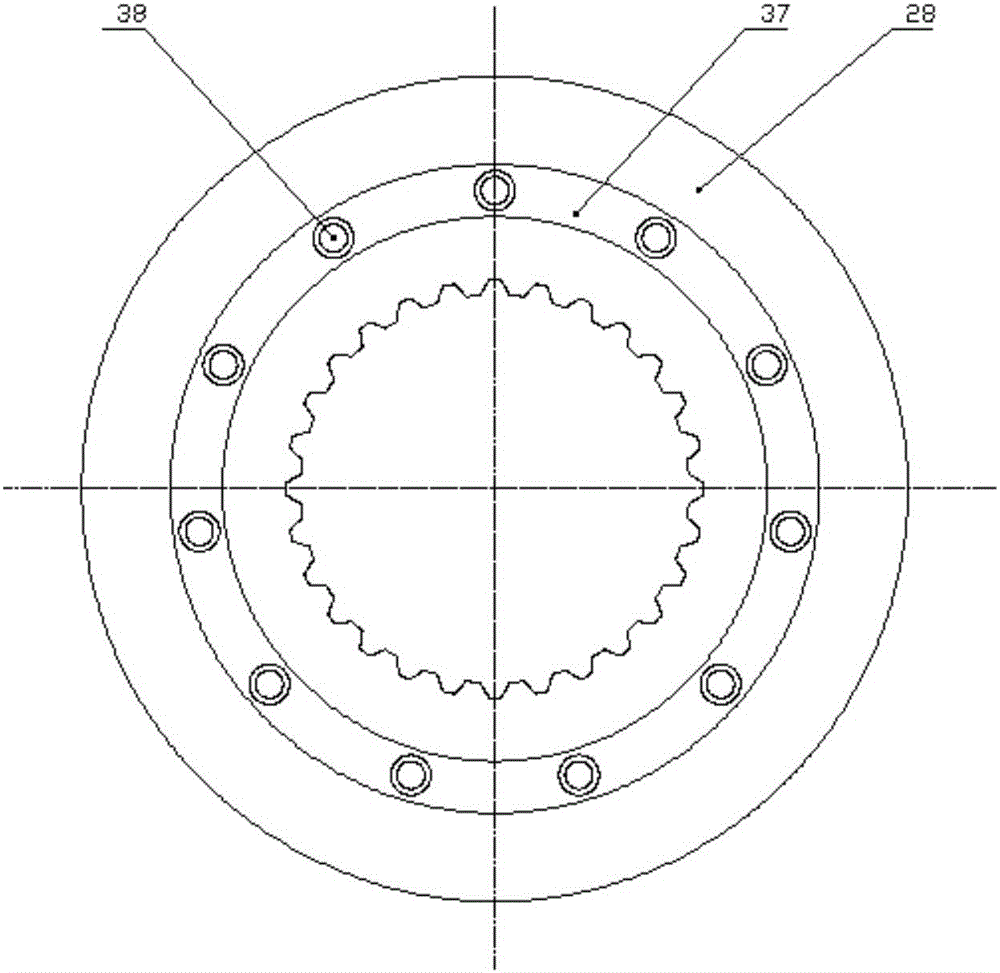

[0033] refer to figure 1 , figure 2 , image 3 , Figure 5, a double-row radial plunger hydraulic retarder with two end face distribution plates, including a transmission shaft 18, the front end of the transmission shaft 18 is connected to the gearbox 50, and the rear end of the transmission shaft 18 is connected to the drive axle through a universal joint 47 48 connection, the first cylinder 28 and the second cylinder 19 are installed side by side in the middle of the transmission shaft 18, and are connected with the transmission shaft 18 through splines, and the first cylinder 28 is opened on the side opposite to the second cylinder 19. There is an annular groove 37, and the cylinder middle ring 20 is installed in the annular groove 37 and pressed against the second cylinder 19, and a row of diameters are parallelly opened on the outer circumferences of the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com