Braking method of a vehicle booster braking device

A braking device and vehicle technology, applied in the direction of braking transmission, brakes, vehicle components, etc., can solve the problems of affecting braking performance, unable to generate pressure oil, unable to realize power-assisted braking, etc., and achieve the effect of preventing traffic accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and given embodiment, the present invention will be further described:

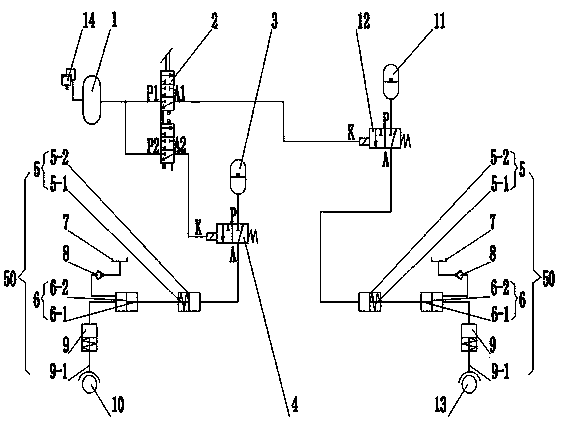

[0019] Such as figure 1 As shown, a vehicle booster brake device includes a brake mechanism 50, a front wheel brake 10 and a rear wheel brake 13, and the brake mechanism 50 includes a booster valve 5, a brake valve 6, an oil cup 7, an oil supply sheet The booster valve 5 has a first piston rod 5-1 and a first piston 5-2, and the brake valve 6 has a second piston rod 6-1 and a second piston 6 -2, the first piston rod 5-1 of the booster valve 5 is fixedly connected or integrated with the second piston rod 6-1 of the brake valve 6, and the oil cup 7 is connected to the brake valve through the oil supply check valve 8 The rodless chamber of the valve 6 is connected, and the rodless chamber of the brake valve 6 is connected with the rodless chamber of the brake cylinder 9, and the third piston rod 9-1 of the brake cylinder 9 is connected with the front whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com