A quadruped robot platform

A quadruped robot and platform technology, applied in motor vehicles, transportation and packaging, etc., can solve the problems of quadruped robot parts damage, reduced reliability and durability of parts, poor bearing capacity of series mechanisms, etc., to improve energy Utilization efficiency, fast motion response speed, and the effect of reducing motion inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiment is a specific implementation carried out on the premise of the technical solution of the present invention, and provides detailed implementation methods and processes, but it is not used as a limitation to the scope of protection of the claims of the present application.

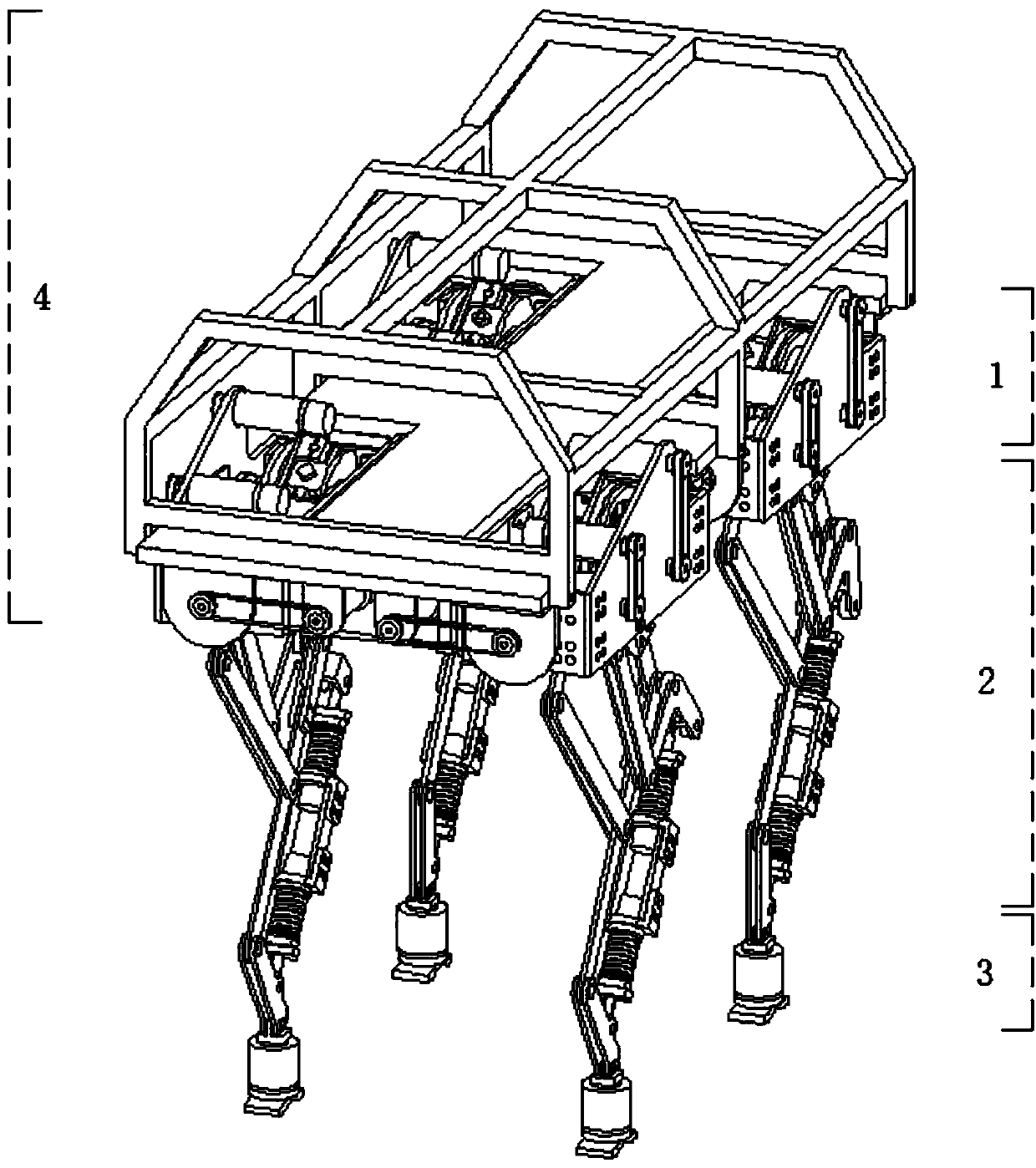

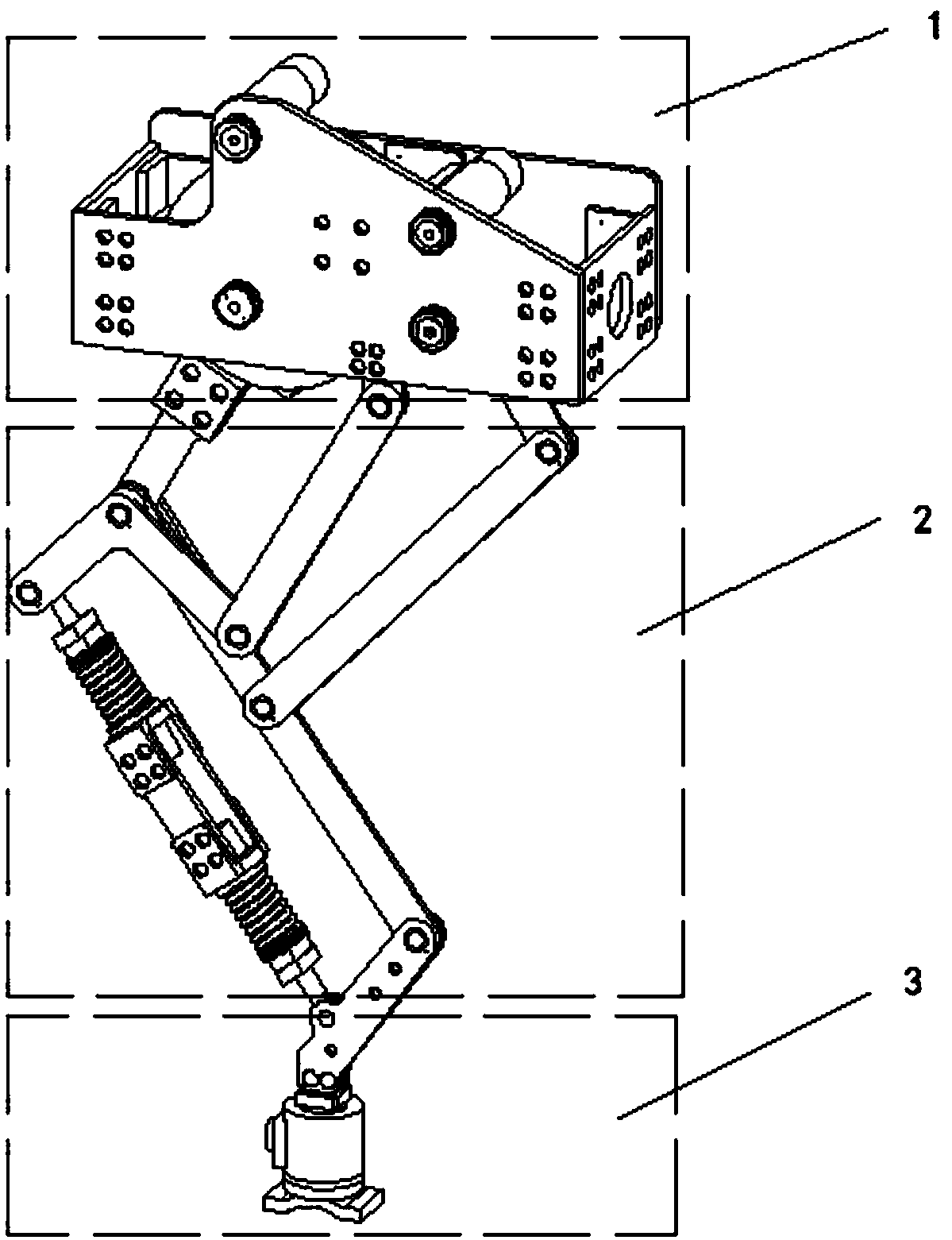

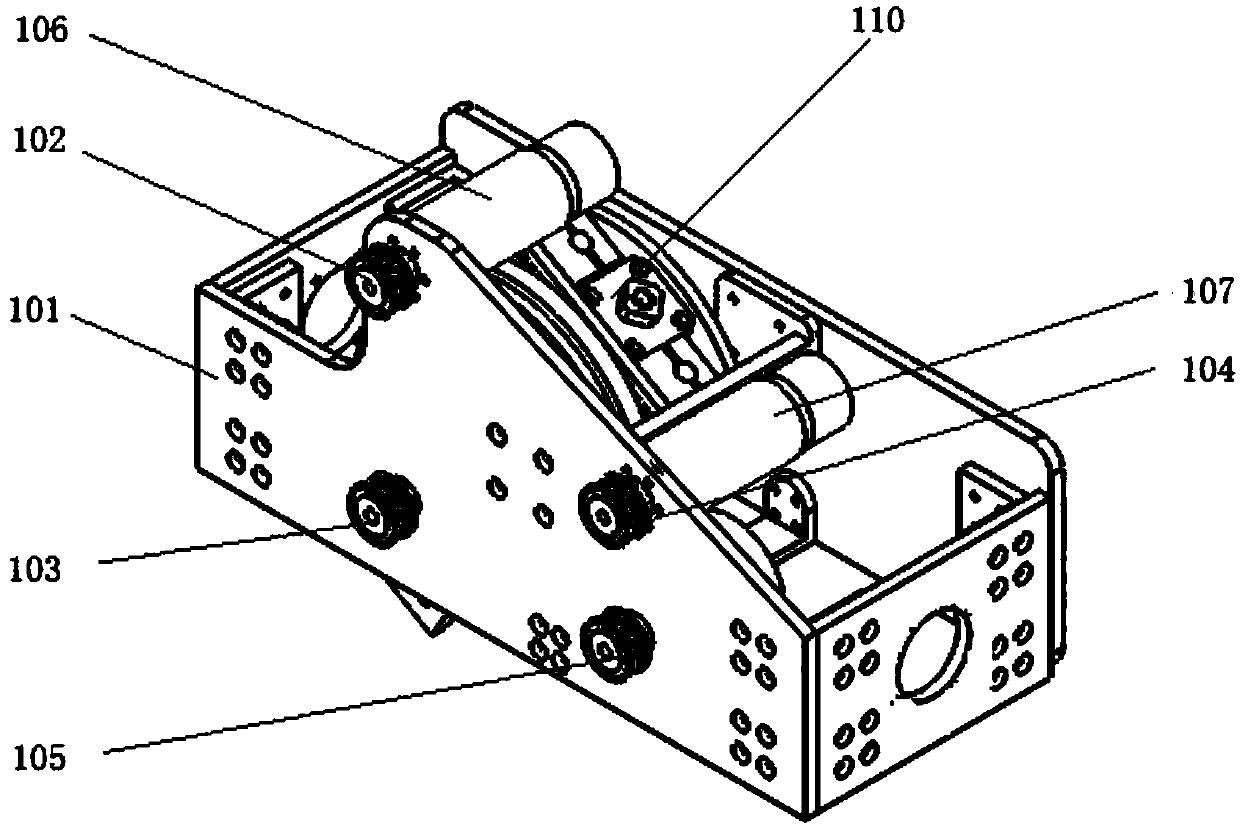

[0035] A kind of quadruped robot platform designed by the present invention (abbreviation platform, see Figure 1-12 ) includes a fuselage model and a leg module, characterized in that the leg module is a flexible leg of a planar five-bar mechanism, and the flexible leg or leg structure adopts a modular design, including a pitch drive joint (module) 1, a link mechanism (module) 2 and toe (module) 3; one end of the link mechanism module 2 is connected to the pitch drive joint module 1, and the other end is connected to the toe module 3; the pitch movement joint module 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com