Toothed belt depth indicator

A technology of depth indicator and toothed belt, applied in the direction of belt/chain/gear, transmission device, elevator, etc., can solve the problems of reduced work reliability, low production efficiency, time-consuming and laborious maintenance, etc., to reduce the amount of machining, The effect of high work reliability and production cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

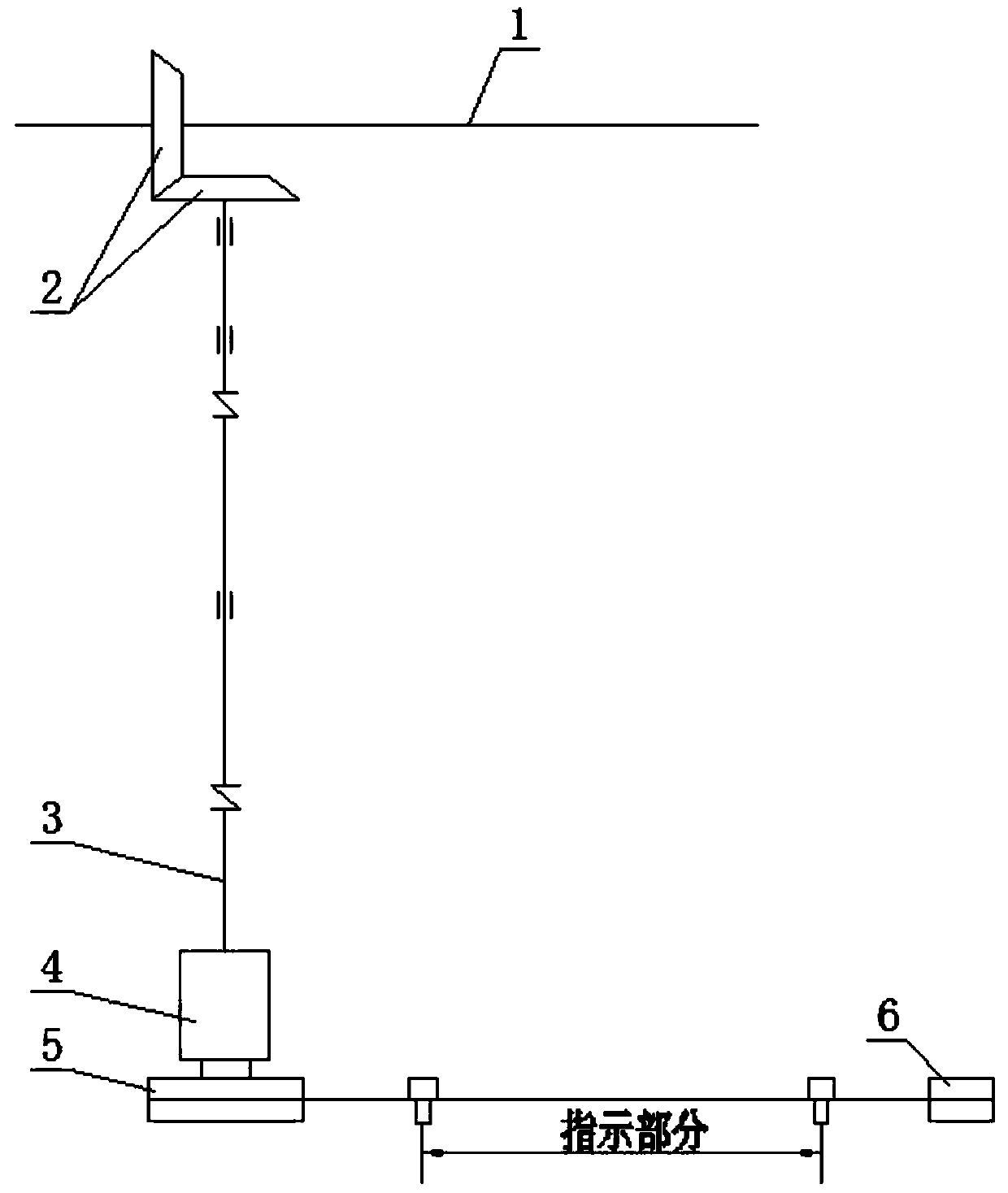

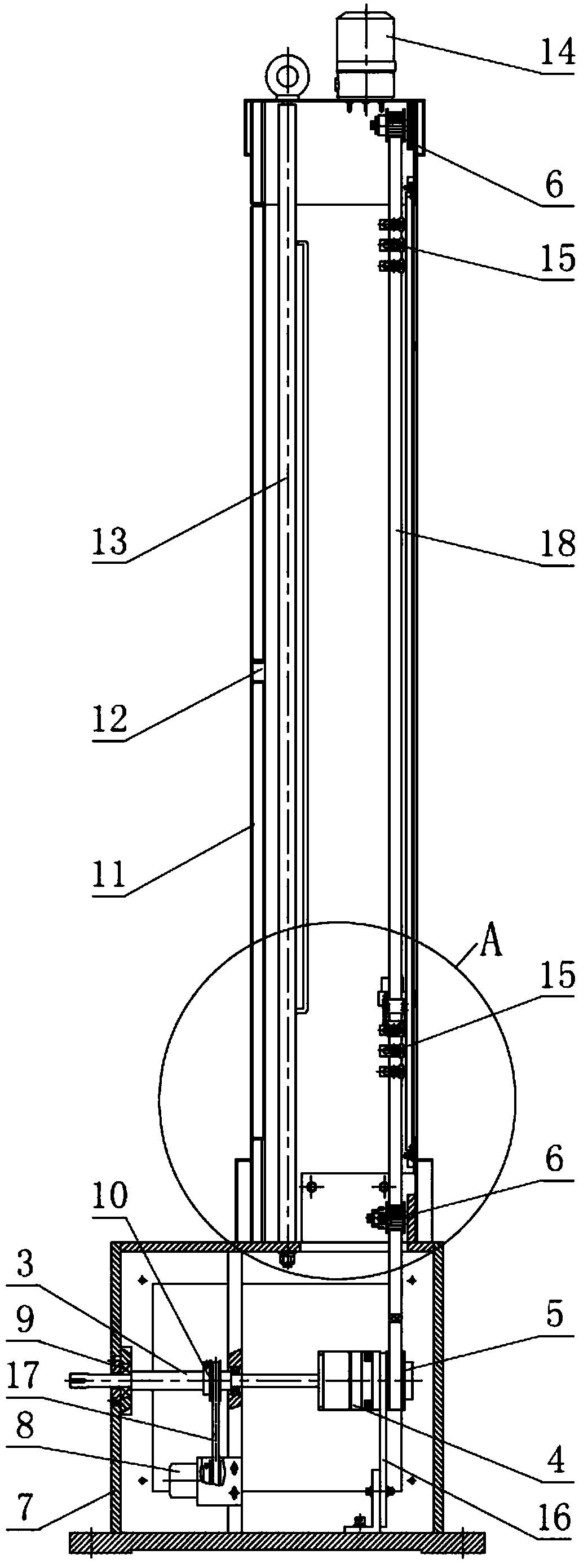

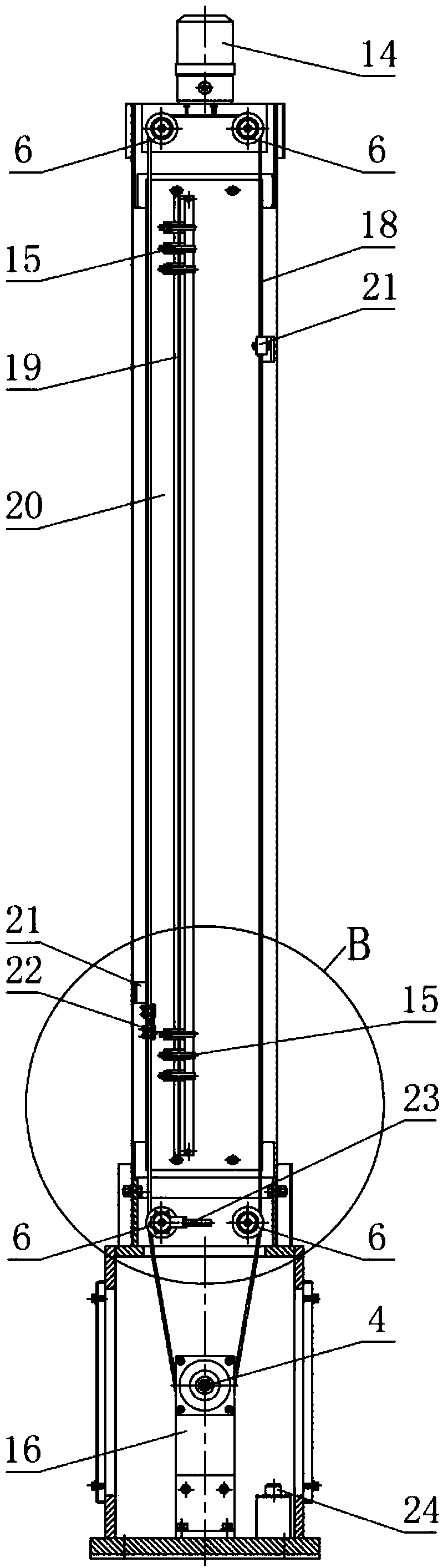

[0034] Such as Figure 1-Figure 8As shown, the toothed belt depth indicator includes a base 7 and a housing 12 located on the top of the base 7. The housing 12 is in the shape of a cuboid, and a connection is provided between the top of the housing 12 and the upper surface of the base 7. Column 13 to increase connection strength. The base 7 is supported by a bearing 9 with a horizontal transmission shaft 3, one end of the horizontal transmission shaft 3 protrudes from the base 7, and is used to connect with the hoist main shaft 1 by a transmission mechanism, and the other end of the horizontal transmission shaft 3 is connected to the cycloid The input end of the reducer 4 is connected, that is, the end of the horizontal transmission shaft 3 is connected with the coupling of the input end of the cycloidal reducer 4, and the axis line of the horizontal transmission shaft 3 is connected with the shaft of the cycloidal reducer 4. Heart lines coincide. The output shaft of the cyc...

Embodiment 2

[0042] In this embodiment, there is one pointer 21, which is located on the left or right side of the panel 20, that is, fixed on the belt body on the left or right side of the timing belt I18. Suitable for hoists with single drum. Others are the same as embodiment 1.

Embodiment 3

[0044] In this embodiment, the horizontal transmission shaft 3 is connected to the input shaft of the cycloid reducer 4 by a pair of gear transmission pairs, and the axis of the horizontal transmission shaft 3 is parallel to the axis of the cycloid reducer 4 . It is applicable to the hoist with the direction opposite to that of the drum in the first embodiment. Others are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com