Vertical elevator with high-strength locking pin

A locking pin, high-strength technology, used in elevators, transportation and packaging, etc., can solve the problems of limited effect, paralysis of the anti-fall system, casualties of passengers in the elevator, etc., to achieve the effect of reasonable structure, convenient and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

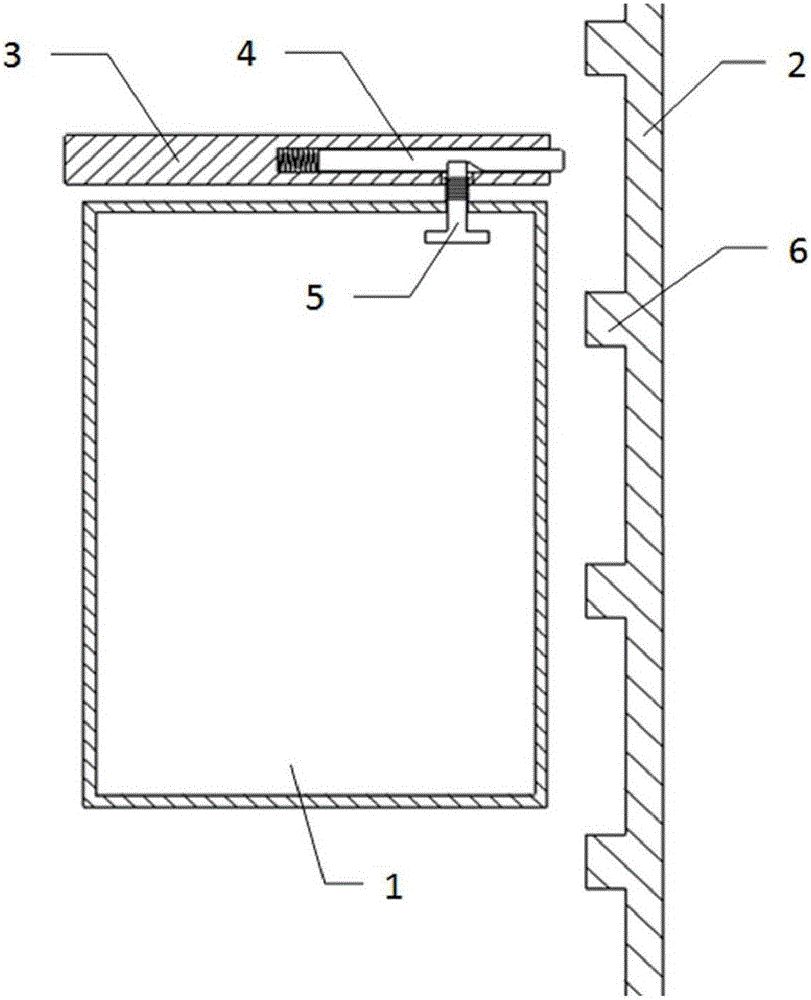

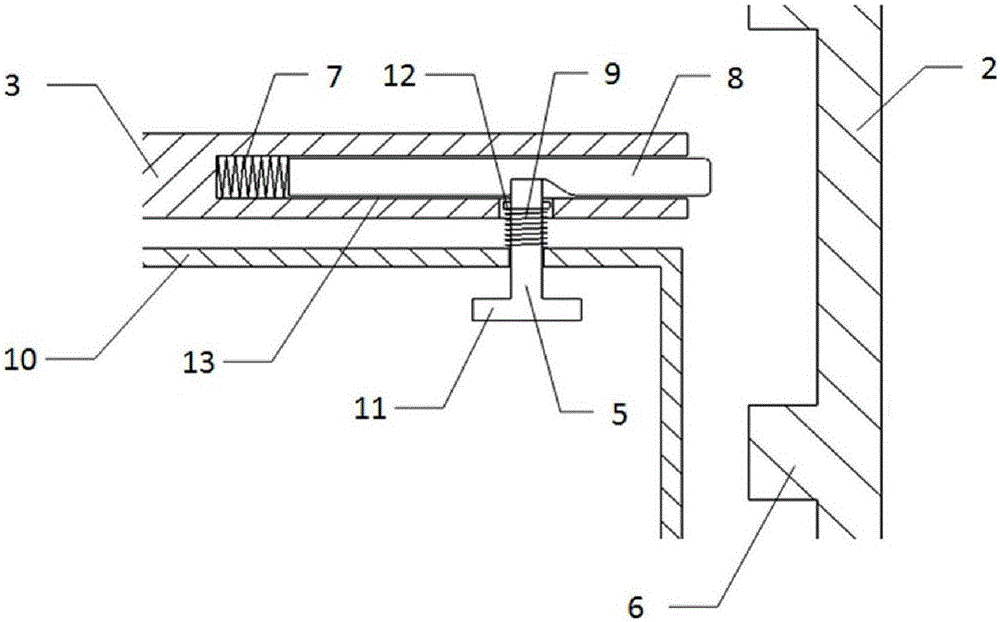

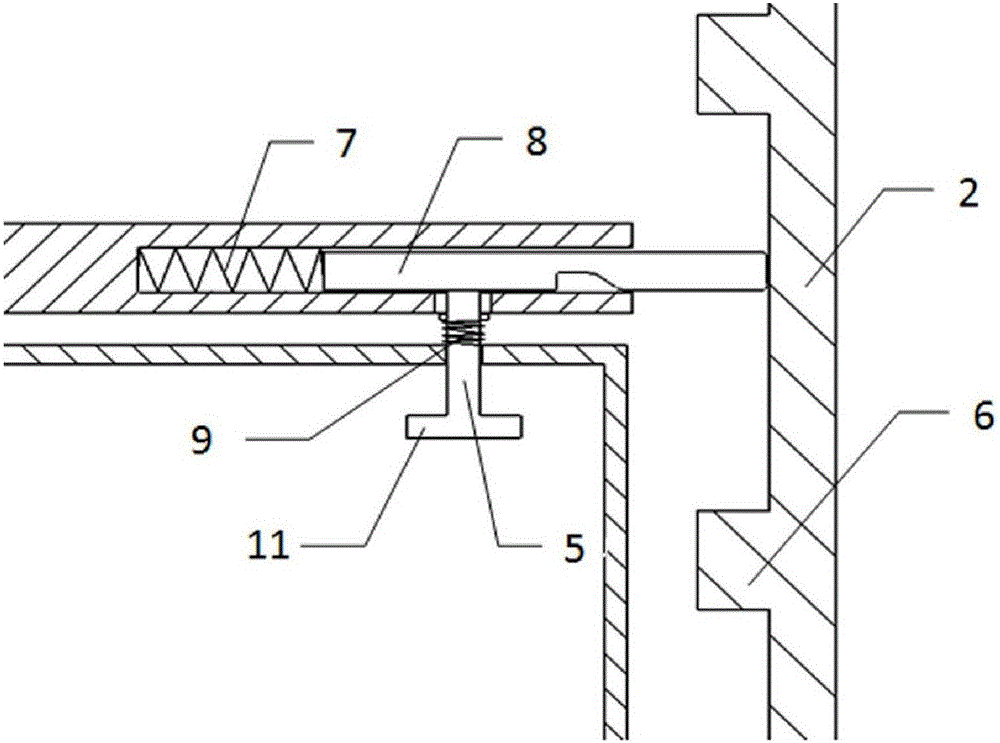

[0021] A kind of vertical elevator with high-strength locking pin of the present invention, as figure 1 with figure 2 with Figure 5 As shown, it includes a car 1, a shaft wall 2, a car frame 3, a locking device 4, a joystick 5, and a block 6, wherein the locking device 4 includes a first elastic member 7 and a locking pin 8, and the first One end of the elastic member 7 is connected with the locking pin 8, and the other end is connected with the car frame 3; the joystick 5 is provided with a second elastic member 9 and a limit block 12 for installing the second elastic member 9, and the second elastic One end of the piece 9 is connected with the limit block 12, and the other end is connected with the car shell 10 of the car 1, and the end of the joystick 5 inside the car 1 is provided with a handle 11. The car frame 3 is provided with a guide rail 13, the locking device 4 is installed on the guide rail 13, and can move axially under the regulation of the guide rail 13; one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com