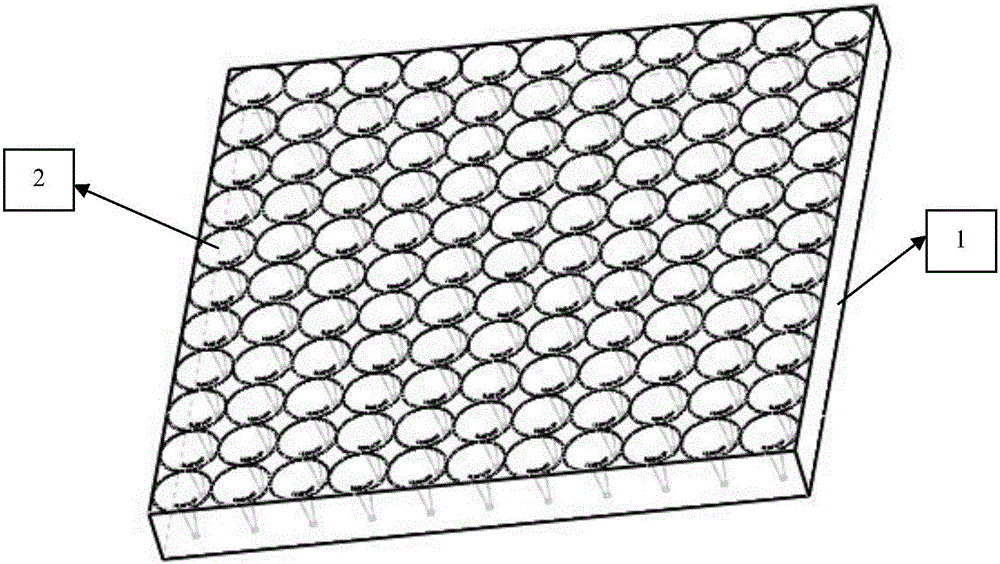

Conical micro-pore array and preparation method thereof

A microhole array, tapered technology, applied in the field of material processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

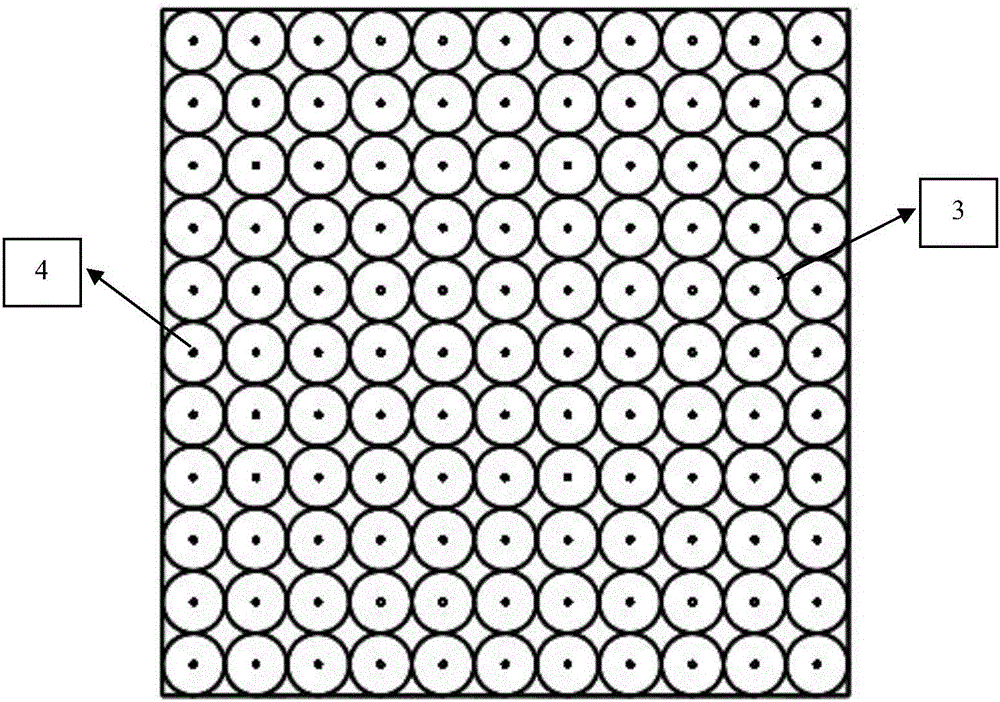

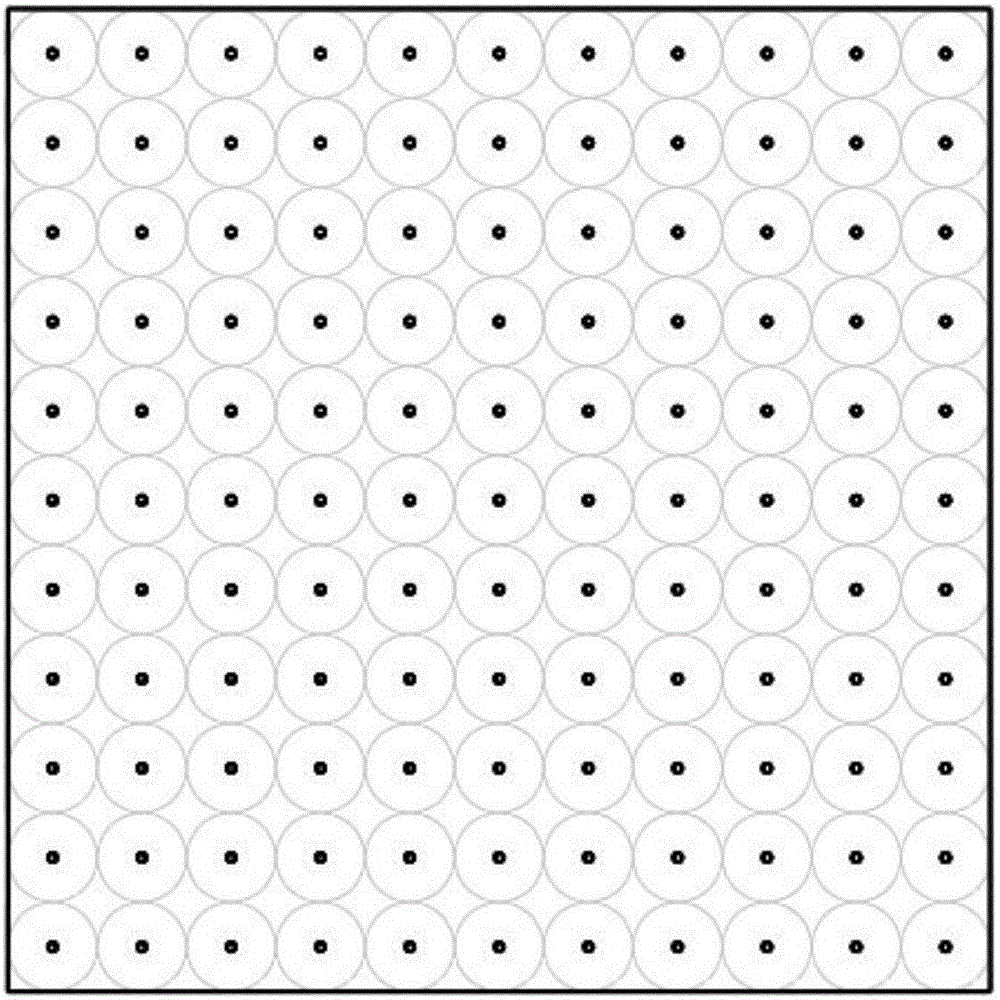

[0030] The diamond film is selected as a non-metallic film with a size of 5x5mm and a thickness of 0.2mm; before the non-metallic film is processed, the upper and lower surfaces of the film are ground and polished to make the surface roughness 0.1-1μm, and then soaked in alcohol and ultrasonically cleaned for 20 minutes to remove the attached Impurities and oil stains are then dried to obtain a non-metallic film for use;

[0031] Create a graphic file of the microwell array, use the graphic design software to design the microwell entrance pattern with an aperture diameter of 20 μm, and a distance between the centerlines of the microholes of 100 μm, turn on the fiber pulse laser (Hantong HT-20F laser equipment), and place the non-metallic film on the working surface. On the stage, adjust the focus of the laser so that the laser focus falls on the surface of the film, import the graphics file, set the wavelength of the fiber pulse laser to 1064nm, the power to 20w, and set the la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com