Fusion gene indoor quality control product, manufacturing method and recipe of fixing solution of fusion gene indoor quality control product

A technology that integrates genes and indoor quality control. It is applied in the fields of life science and biology and can solve the problems of not being on the market.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

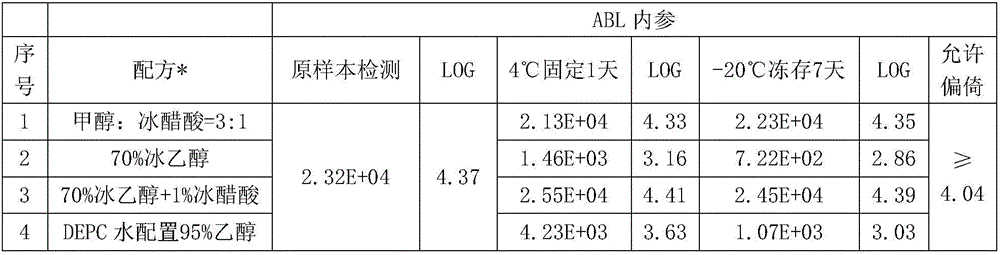

[0030] Extraction of nucleated cells from whole blood and fixation of cell suspension: Add 1ml 1× red blood cell lysate into a 1.5ml centrifuge tube, take 0.5ml of whole blood sample, mix by inverting. Centrifuge at 4000rpm for 3min, discard the supernatant, add erythrocyte lysate to wash once, and add 50ul of fixative solution equal to the volume of the cell pellet, which is the prepared quality control product.

[0031] The fixative includes 4°C pre-cooled absolute ethanol (AR), 70-75ml; glacial acetic acid (AR), 1-5ml; DEPC water to 100ml; refrigerated storage at 4°C.

Embodiment 2

[0033] RNA extraction of the quality control product: take the quality control product in Example 1 and add 1 ml of normal saline, let it stand for 5 minutes, then centrifuge and discard the supernatant. Add 1ml of normal saline to wash again. Add 1 ml Total RNA Isolation Reagent, pipette repeatedly until no obvious cell clumps, add 200 μl of chloroform, vortex and mix for 30 seconds, and let stand on ice for 10 minutes. Centrifuge at 14,000rpm at 4°C for 10min. Use a pipette to draw 450 μl of the supernatant and transfer it to another centrifuge tube, add an equal volume of pre-cooled isopropanol, invert and mix well, and then let stand on ice for 10 minutes. Centrifuge at 14,000rpm at 4°C for 10min. Then wash and centrifuge once with 75% ethanol and absolute ethanol respectively. Dry at room temperature for 5 min, add 50 μl DEPC-H2O to dissolve.

Embodiment 3

[0035] Reverse transcription: Take 4ul of the RNA solution in Example 2 (concentration about 200ng / ul), add 1ul Primer mix (ReverTra Ace qPCR RT Kit) and 3ul DEPC-H2O, mix well, and pre-denature at 70°C for 5 minutes; after quenching on ice for 1 minute, add 5 *RT buffer 4ul (ReverTra Ace qPCR RT Kit), Enzyme Mix 1ul (ReverTra Ace qPCR RT Kit), and add DEPC-H20 7ul to a total volume of 20ul. After reacting at 37°C for 60 minutes, it was inactivated at 98°C for 5 minutes, and the obtained cDNA was the quality control product to be tested.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com