Electrolytic gold extraction machine

A gold machine and electrolyte technology, applied in electrolytic components, electrolytic process, cells, etc., can solve the problems that gold cannot be converted into cash in time, increase production capital investment, reduce activated carbon adsorption activity and service life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

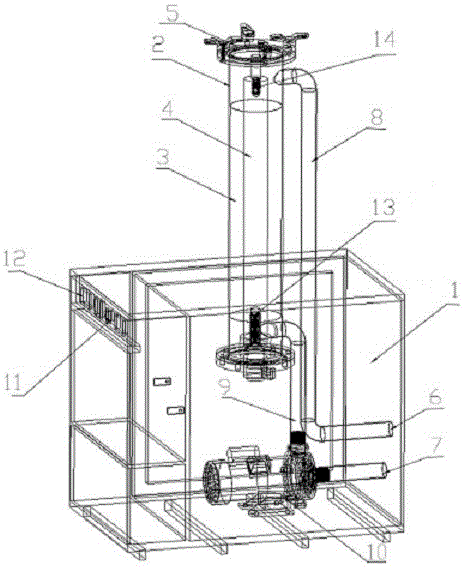

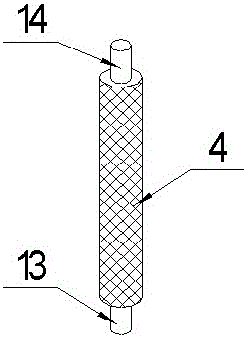

[0025] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-2 As shown, an electrolytic gold extraction machine includes a chassis (1), the upper surface of the chassis (1) is inserted into a gold extraction unit whose lower end extends into the chassis (1), and the gold extraction unit is inserted into the chassis (1). (1) The upper surface, and the lower end extends into the main body of the gold extraction unit (2) in the chassis (1), the anode tube (3) inserted in the main body of the gold extraction unit (2), the anode tube (3) inserted in the Inside, the cathode rod (4) that is conductively connected to it, the sealing cover (5) set at the upper opening of the gold extraction unit body (2), and the water inlet (7) and water outlet respectively set on the side surface of the chassis (1) (6), one end is connected to the water inlet (7), and the other end is connected to the anode tube (3) inside the outlet pipe (8), o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap