Subsea production tree and tubing hanger flushing device

A technology of tubing hanger and underwater Christmas tree, which is applied in the direction of flushing wellbore, earthwork drilling, wellbore/well components, etc. It can solve the problems of lack of equipment, unqualified test, and reduced work efficiency, so as to improve the working life , Ensure safety and reliability, and improve reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

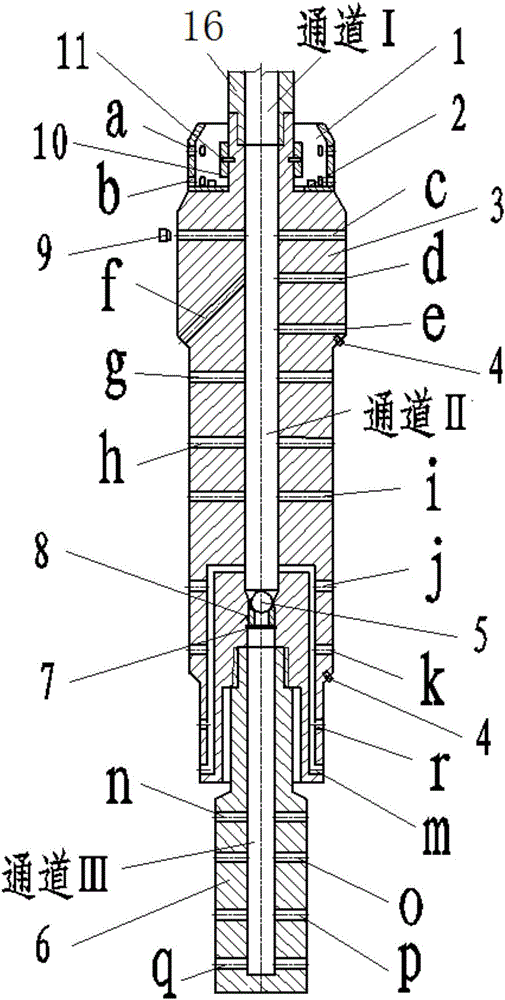

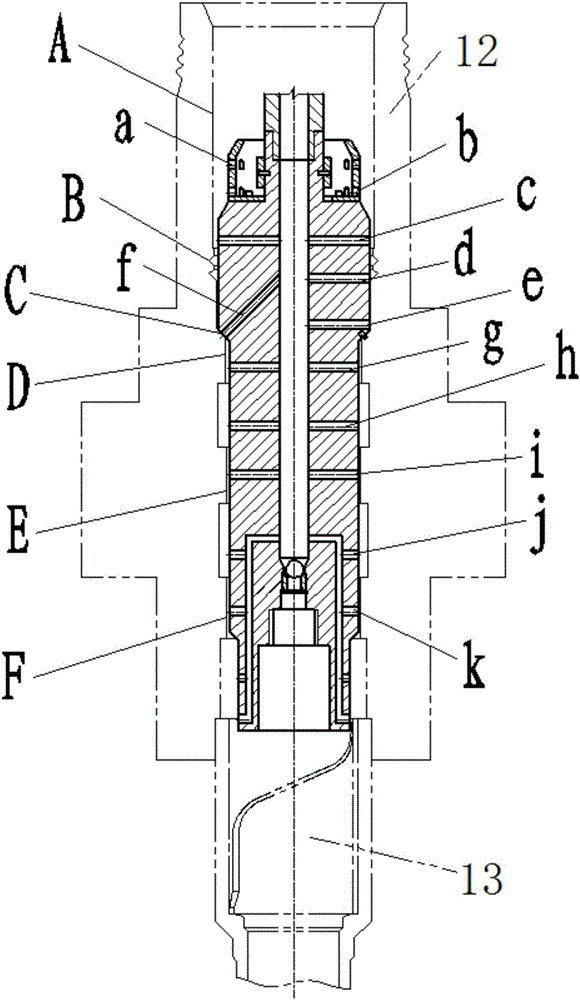

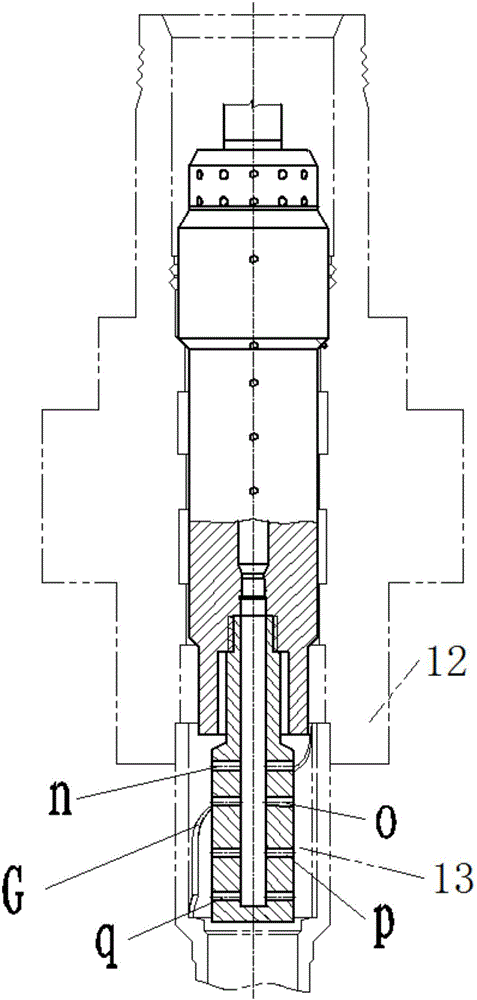

[0017] refer to figure 1 The structure of the device of the present invention (hereinafter referred to as the flushing device) is to include a debris collection bucket 1, the bottom of the debris collection bucket 1 is fixedly connected with the upper step surface of the device main body 3 through a fastener I2, and the outer edge of the debris collection bucket 1 is It is in the shape of an inverted cone, and there are upper discharge holes a and lower discharge holes b evenly distributed along the circumferential direction on the outer wall of the cuttings collection barrel 1; an adsorption magnet 10 is arranged in the inner cavity of the cuttings barrel 1, and the adsorption magnet 10 is made of magnetic material. The adsorption magnet 10 is fixed on the outer cylindrical surface of the device main body 3 through the fastener II11; the deb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com