Exhaust passage of internal combustion engine and internal combustion engine with the same

An exhaust pipe, internal combustion engine technology, applied in the direction of internal combustion piston engine, combustion engine, machine/engine, etc., can solve the problems of structure and details of integrated exhaust pipe, and achieve the effect of improving heat discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

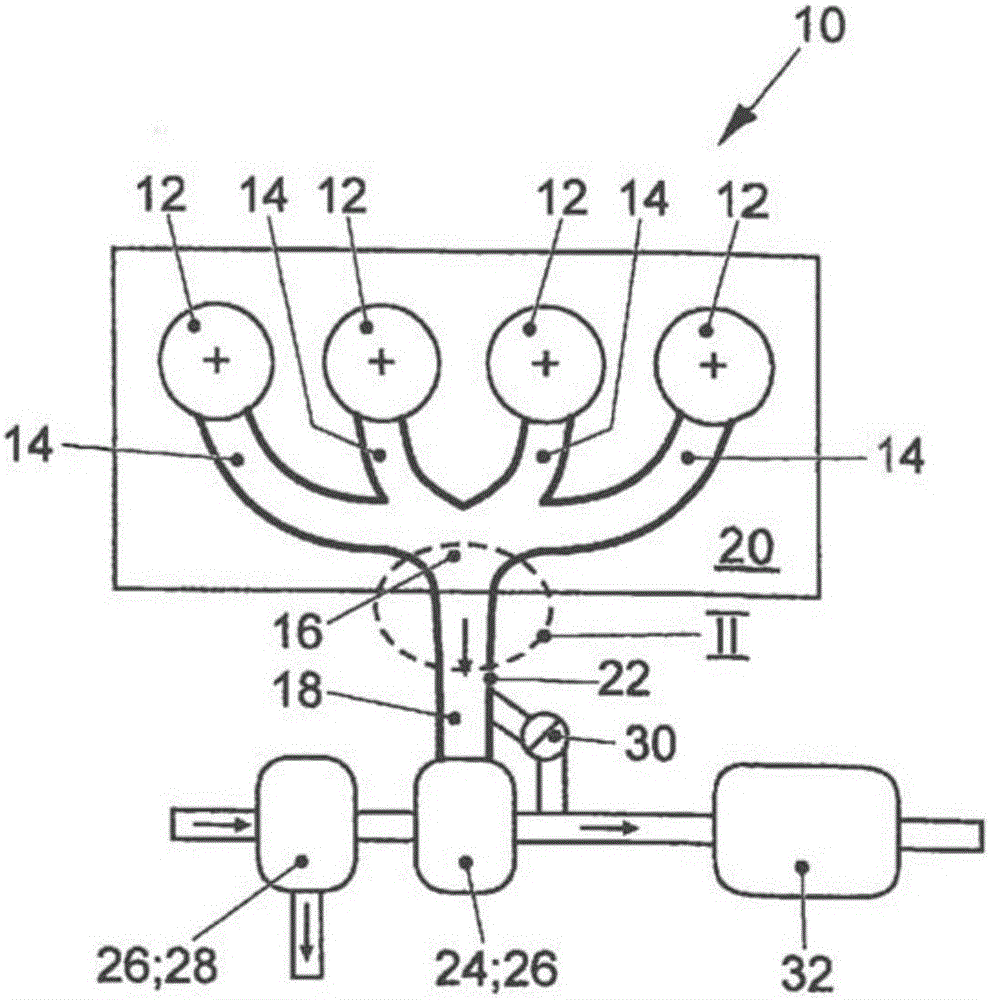

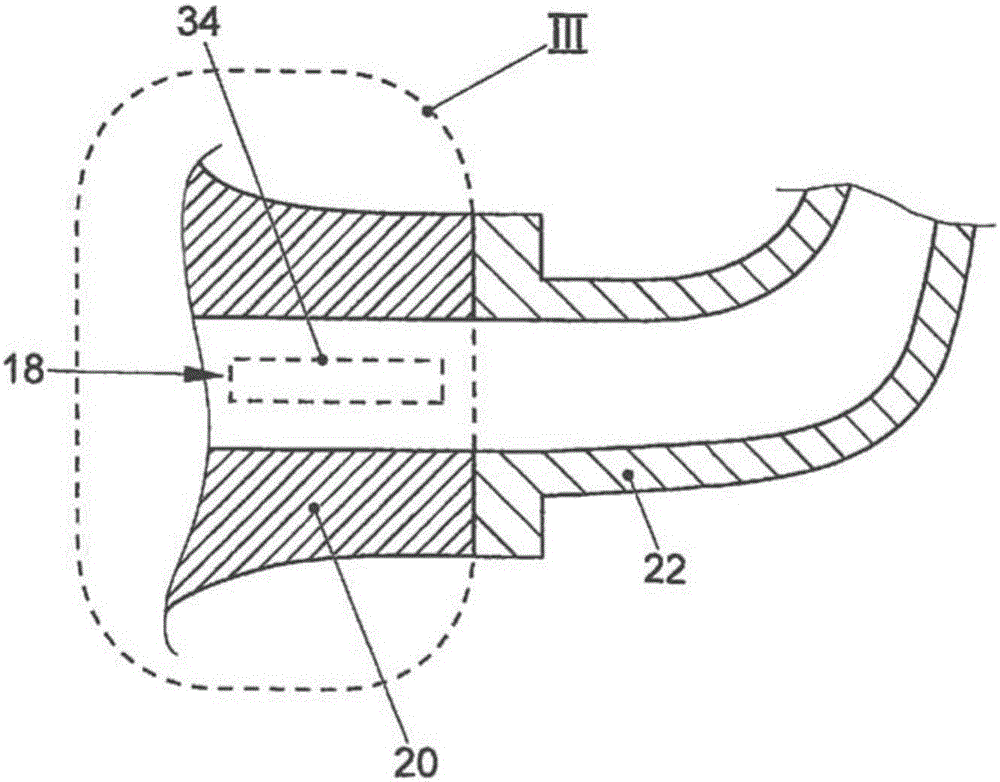

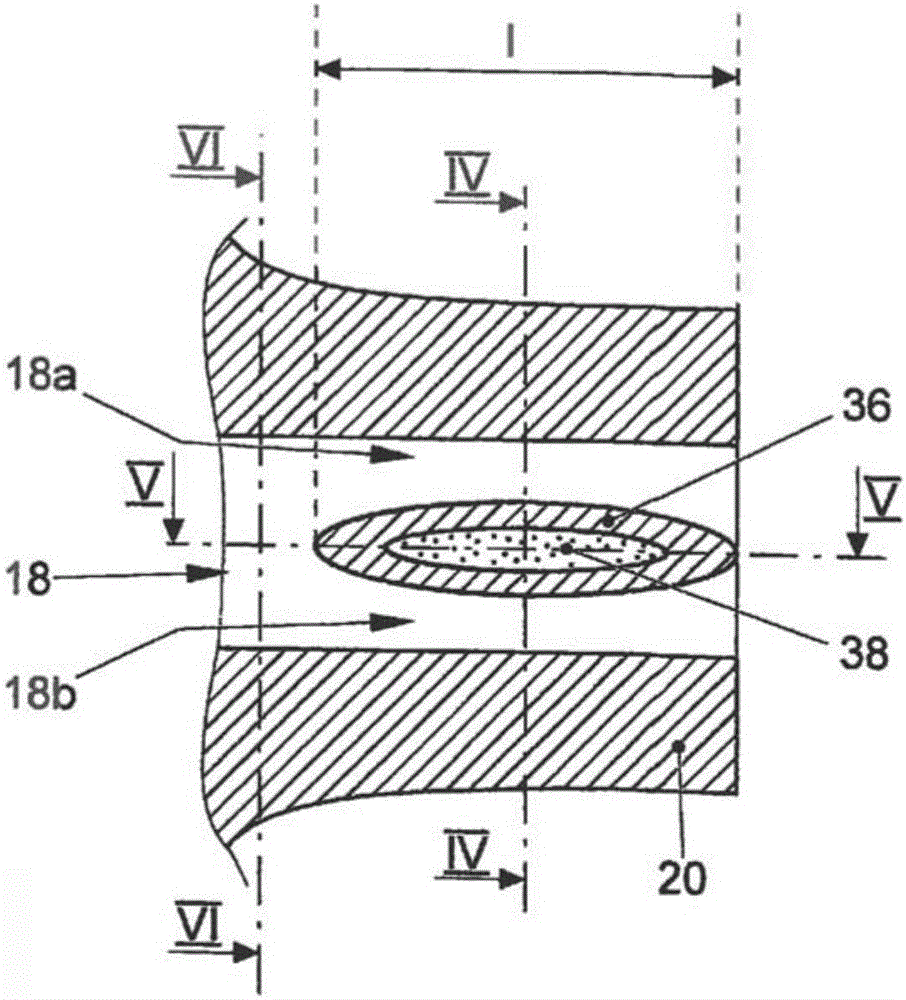

[0027] figure 1 Shown is an internal combustion engine 10 according to the invention with a total of four schematically illustrated cylinders 12 and exhaust gas lines 14 leading from these cylinders 12 , which join together at connection points 16 to a common (total) exhaust gas Tube 18. The connection point 16 is located within the schematically shown cylinder head 20 . Therefore, the exhaust pipe 18 is also referred to as an "integrated exhaust pipe". An intermediate element 22 , which leads to a turbine wheel 24 of an exhaust gas turbocharger 26 , is flanged to the cylinder head 20 . The exhaust gas turbocharger 26 also includes a compressor 28 . Such as figure 1 As shown, the exhaust gas can also be bypassed from the turbine 24 of the exhaust gas turbocharger 26 via a bypass valve 30 serving as a wastegate instead of via the turbine 24 . Arranged downstream of the turbine 24 is an exhaust gas aftertreatment system 32 , for example in the form of a three-way catalytic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com