Mixed-flow turbosupercharger for integration vehicle

A turbocharger, integrated technology, applied in the direction of machines/engines, engine components, internal combustion piston engines, etc., can solve the problems of limited design, low price, reduce the risk of air leakage and deformation, and achieve a clear structure Simplicity, reliability, improved performance, flexible and fast assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

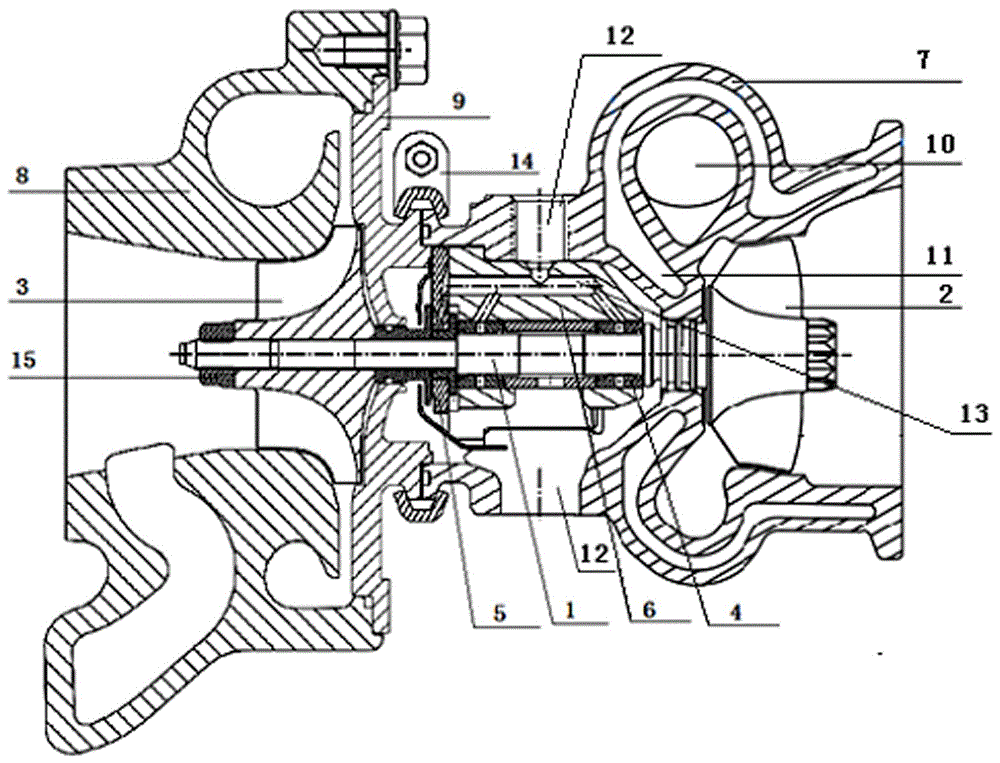

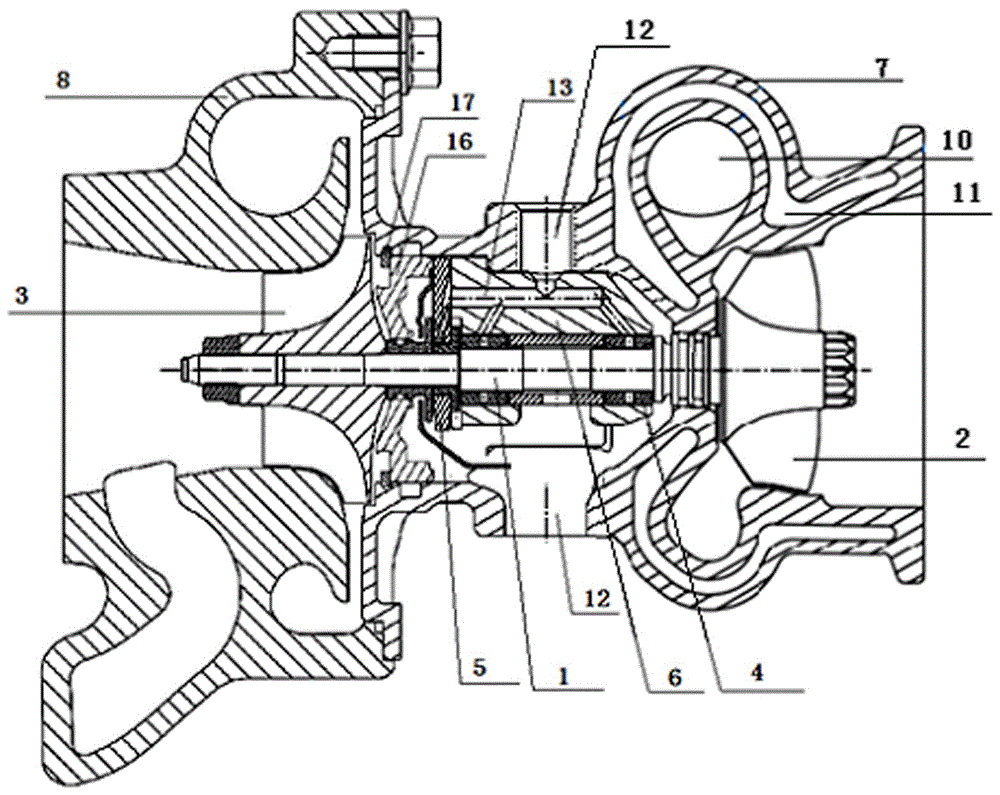

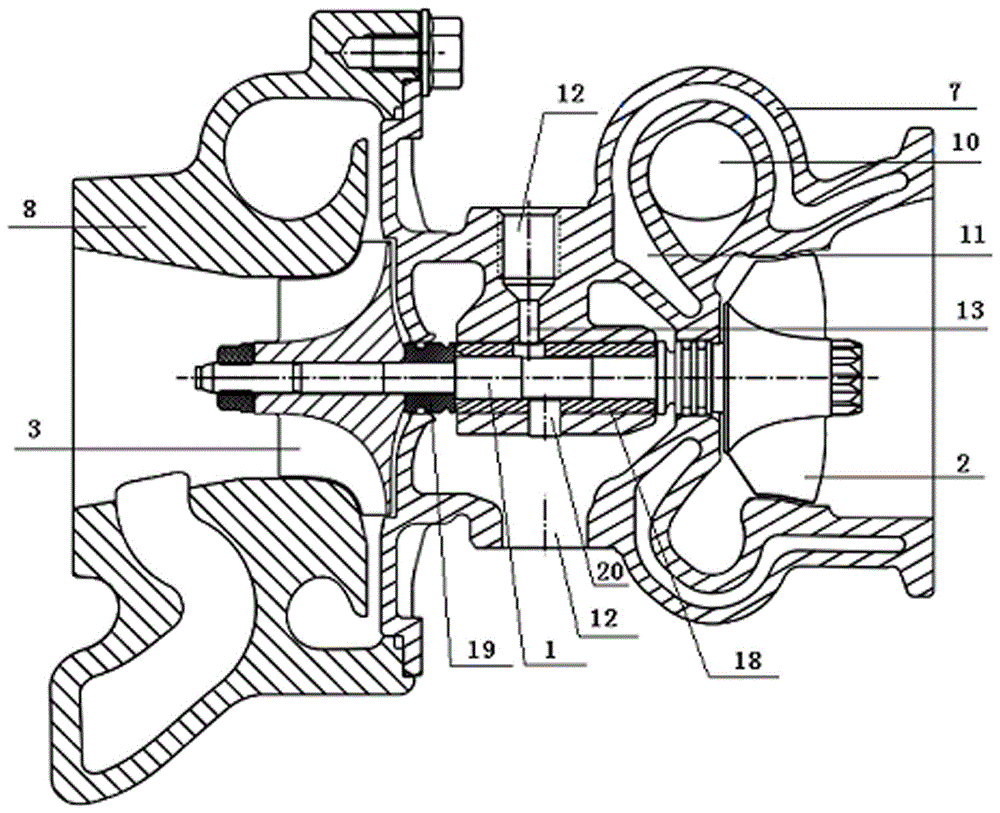

[0034]The invention provides an integrated mixed-flow turbocharger for a vehicle, which includes a rotating structure, a bearing structure, a bearing seat and a housing mechanism; the rotating structure includes a rotating shaft and turbines and impellers arranged at both ends of the rotating shaft; the The bearing structure includes a floating bearing and a thrust bearing ring arranged in the middle of the rotating shaft; the bearing seat is sleeved on the outside of the bearing structure; The integrated turbine casing, the impeller casing sleeved on the outside of the impeller, and the back plate connecting the integrated turbine casing and the impeller casing; wherein, the integrated turbine casing is provided with a vortex channel and a cooling water channel, so The cooling water channel is wrapped on the outside of the vortex channel.

[0035] The setting of the integrated turbine shell makes it possible for the cooling water channel to completely wrap the outer side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com