Integrated motor water pump

A water pump and shell technology, applied in the field of integrated motor water pump, can solve the problems of insufficient compact structure, single structure form, large volume, etc., and achieve the effect of increasing the effective water passage area and saving volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below will describe in detail according to the embodiment shown in accompanying drawing:

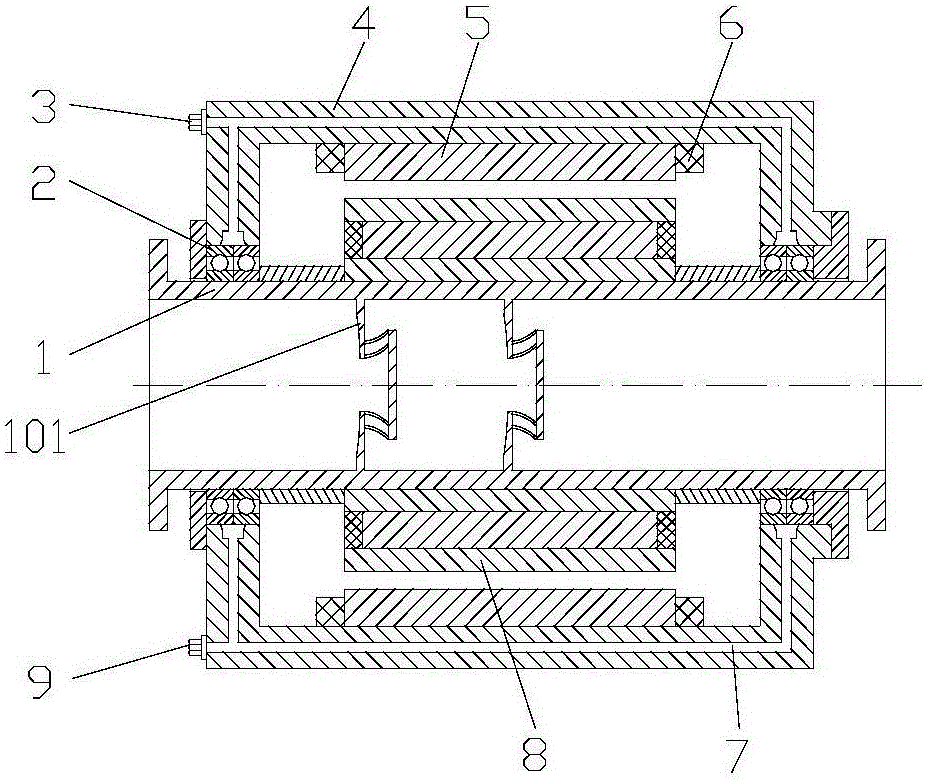

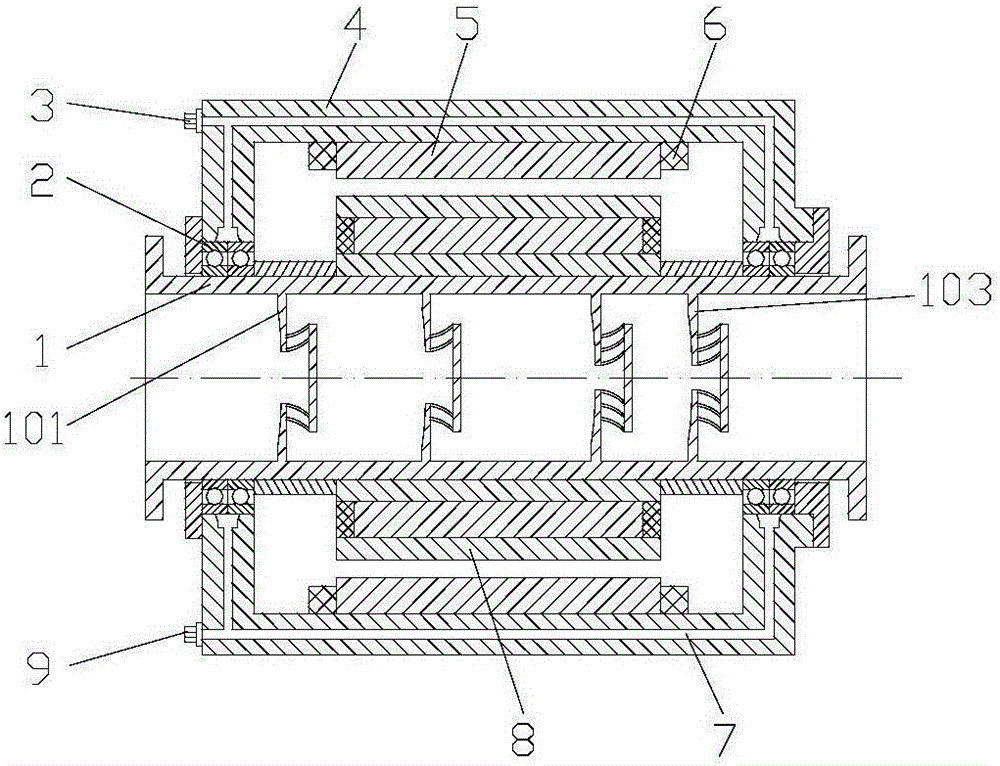

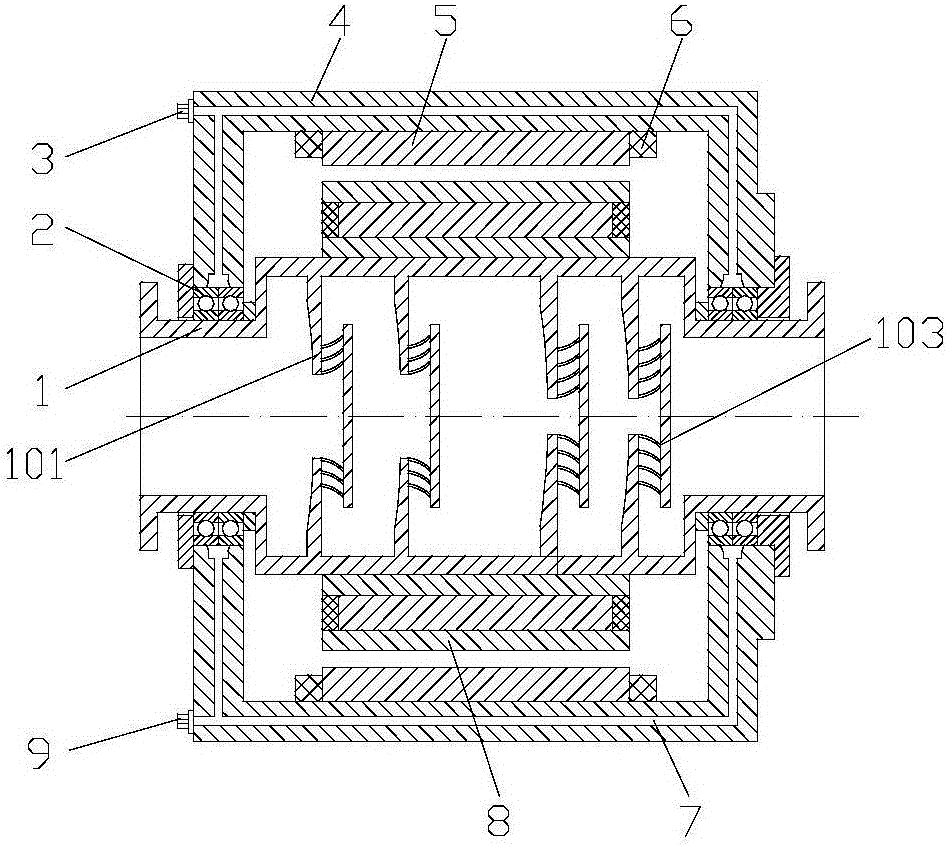

[0016] figure 1 It is a front view schematic diagram of an integrated motor water pump single-stage axial flow pump of the present invention, figure 2 It is a schematic diagram of the front view of an integrated motor water pump segmented multi-stage centrifugal water pump of the present invention, image 3 It is a schematic diagram of the front view of a segmented multistage centrifugal water pump when the inside of the rotating shaft of the integrated motor water pump of the present invention is stepped. It can be seen from the figure that an integrated motor water pump includes a rotor, a stator and a housing (4); the rotor shaft (1) is set on the centerline of the cylindrical housing (4) through a bearing, and The inner wall is provided with a stator core (5), and a stator winding (6) is wound on the stator core (5); the rotor shaft (1) is a hollow structure, that is, a thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com