Detection method for content of ceramic powder of organic ceramic mixture

A detection method and technology of organic ceramics, applied in the field of materials, can solve the problems of inability to accurately detect the content of ceramic powder in organic ceramic mixtures, and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

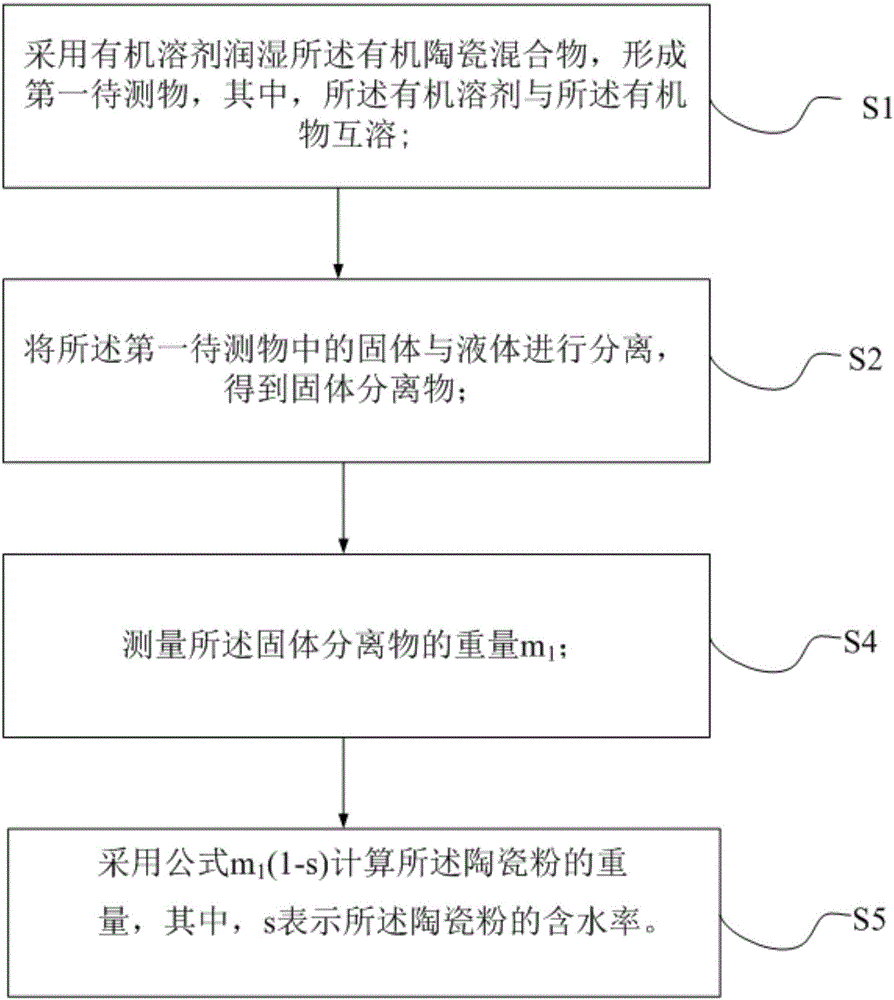

Method used

Image

Examples

Embodiment 1

[0046] 30 grams of resin, 100 grams of ceramic powder are mixed with 15 grams of curing agent to form 145 grams of organic ceramic mixture, and the moisture content of ceramic powder is recorded by the aforementioned measurement method of the application to be 0.05%, so that in organic ceramic mixture, ceramic The weight percent of powder is 100(1-0.05%) / 145=68.93%.

[0047] The detection method specifically includes:

[0048] Step S1, mixing 145g of ethanol with 145g of organic ceramic mixture to form a first analyte.

[0049] In step S2, vacuum filtration is used to separate the solid from the liquid in the first analyte to obtain a solid isolate.

[0050] Step S4, measuring the weight 102g of the above-mentioned solid isolate.

[0051] Step S5, using the formula m 1 ×(1-s) calculates the weight of the above ceramic powder as 101.95g.

[0052] Step S6, using the formula (x / m)×100% to calculate the weight percentage of the above-mentioned ceramic powder in the above-menti...

Embodiment 2

[0054] The difference from Example 1 is that in step S1, 145 g of acetone is mixed with 145 g of organic ceramic mixture to form the first analyte. Step S3 is carried out between step S2 and step S3, that is, drying the above-mentioned solid isolate until the weight of the above-mentioned solid isolate does not change, and the drying temperature is 100°C. And the weight of the solid isolate measured in step S4 is 100.5g; the weight of the above-mentioned ceramic powder calculated in step S5 is 100.45g, and the percentage of the above-mentioned ceramic powder in the organic ceramic mixture calculated in step S6 is 69.3%.

Embodiment 3

[0056] 30 grams of resin, 100 grams of ceramic powder are mixed with 15 grams of curing agent to form 145 grams of organic ceramic mixture, and the moisture content of ceramic powder is recorded by the aforementioned measurement method of the application to be 0.05%, so that in organic ceramic mixture, ceramic The weight percent of powder is 100(1-0.05%) / 145=68.93%.

[0057] The detection method specifically includes:

[0058] Step S1, mixing 145 g of ethyl acetate with 145 g of organic ceramic mixture to form a first analyte.

[0059] In step S2, vacuum filtration is used to separate the solid from the liquid in the first analyte to obtain a solid isolate.

[0060] Repeat step S1 to step S2 in sequence for a total of 4 times, the organic solvent in each repeated step S1 is ethyl acetate, and the solid-liquid separation method in step S2 is vacuum filtration.

[0061] Step S3, drying the above-mentioned solid isolate until the weight of the above-mentioned solid isolate does...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com