A device and method for measuring adsorbed sulfur content based on the principle of solvent dissolution

A sulfur content and solvent technology, applied in the field of exploration and development of high-sulfur natural gas reservoirs, can solve the problems of less research, difficulty in elemental sulfur, lack of reservoirs, etc., and achieve the effect of accurate measurement and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

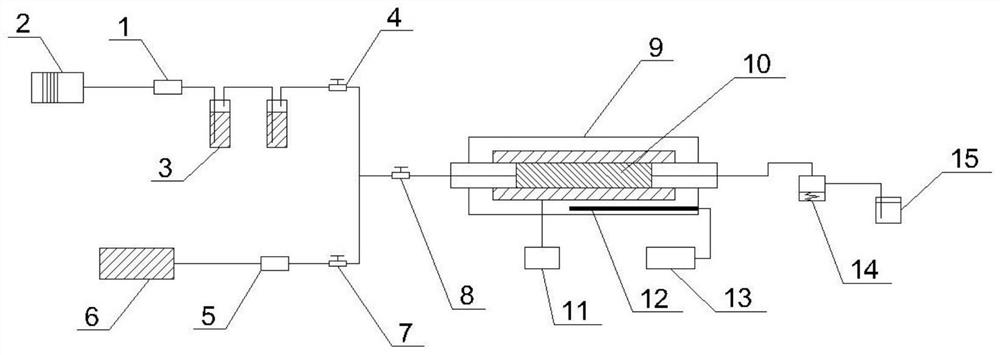

[0041] see figure 1 , a device for measuring adsorbed sulfur content based on the principle of solvent dissolution, a simulated rock core 10 is arranged inside the high-temperature and high-pressure core holder 9, and the high-temperature and high-pressure sulfur-resistant reaction kettle 2 and the solvent container 6 are connected in parallel to the high-temperature and high-pressure core holder through branch pipelines One end of the device 9, the connecting pipeline extends into the inside of the high-temperature and high-pressure rock core holder 9, and the high-temperature, high-pressure sulfur-resisting reactor 2 is filled with the simulated natural gas required in the gas displacement process, and is supplied to the high-temperature, high-pressure, sulfur-resisting reactor 2 according to the gas ratio required for the experiment. 2, and the high-temperature and high-pressure sulfur-resistant reactor 2 can also heat the gas, so that the simulated natural gas can be closer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com