Photocurable and thermally curable resin composition and dry film type solder resist

A thermosetting resin and photocuring technology, applied in optics, optomechanical equipment, photosensitive materials for optomechanical equipment, etc., can solve the problem of not being able to properly meet PCT tolerance, TCT heat resistance, HAST tolerance , Solder resist does not have problems such as high glass transition temperature heat resistance and reliability, and achieves excellent heat resistance reliability, low thermal expansion coefficient, and high developability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

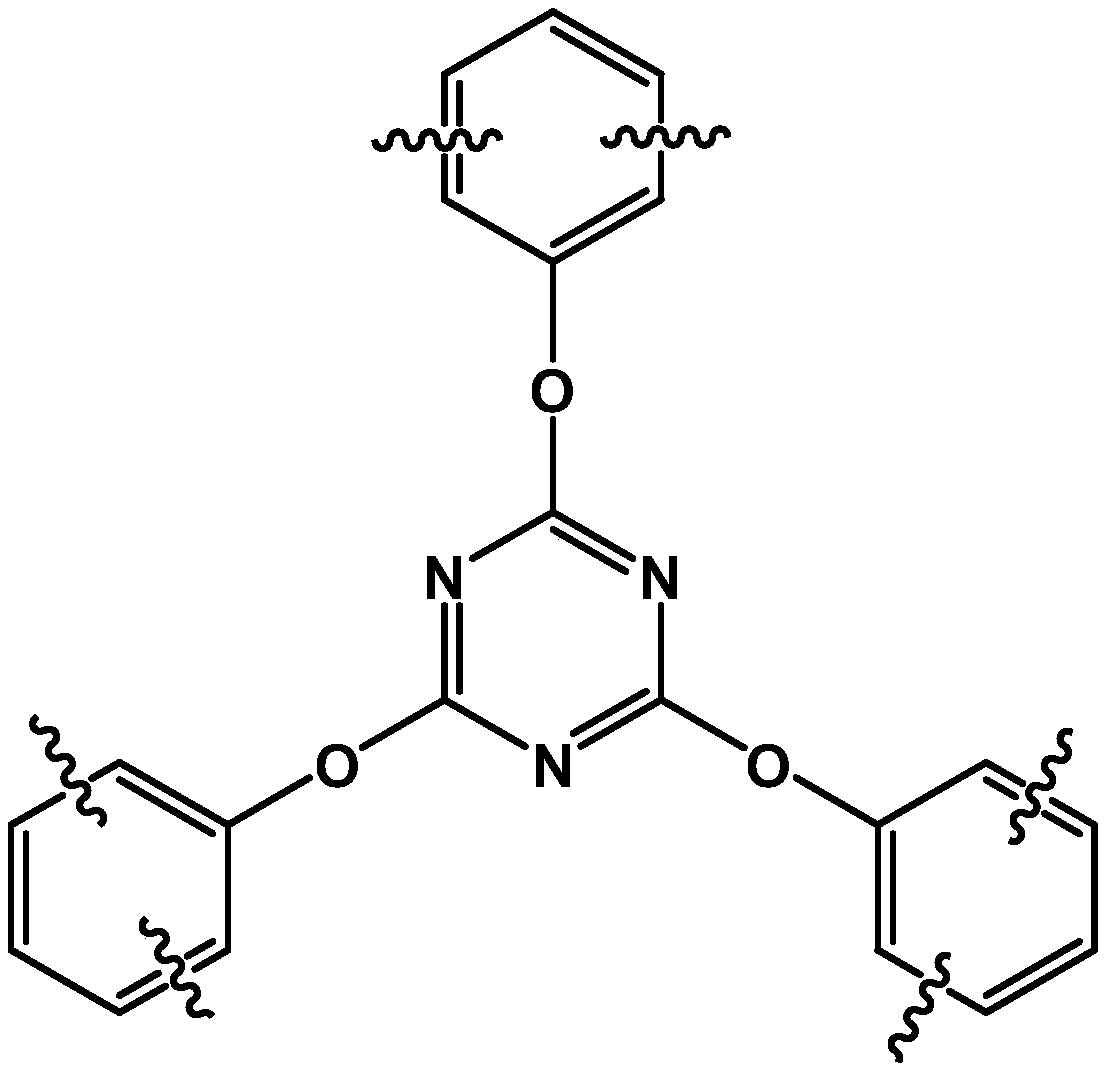

Method used

Image

Examples

Embodiment 1

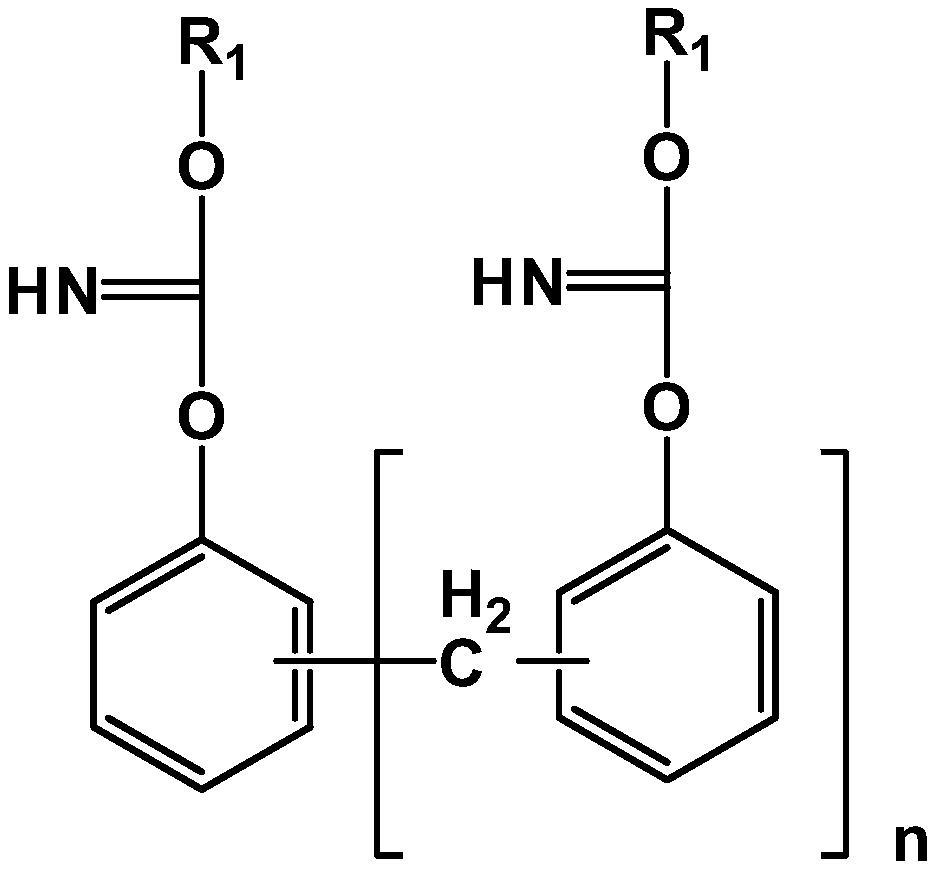

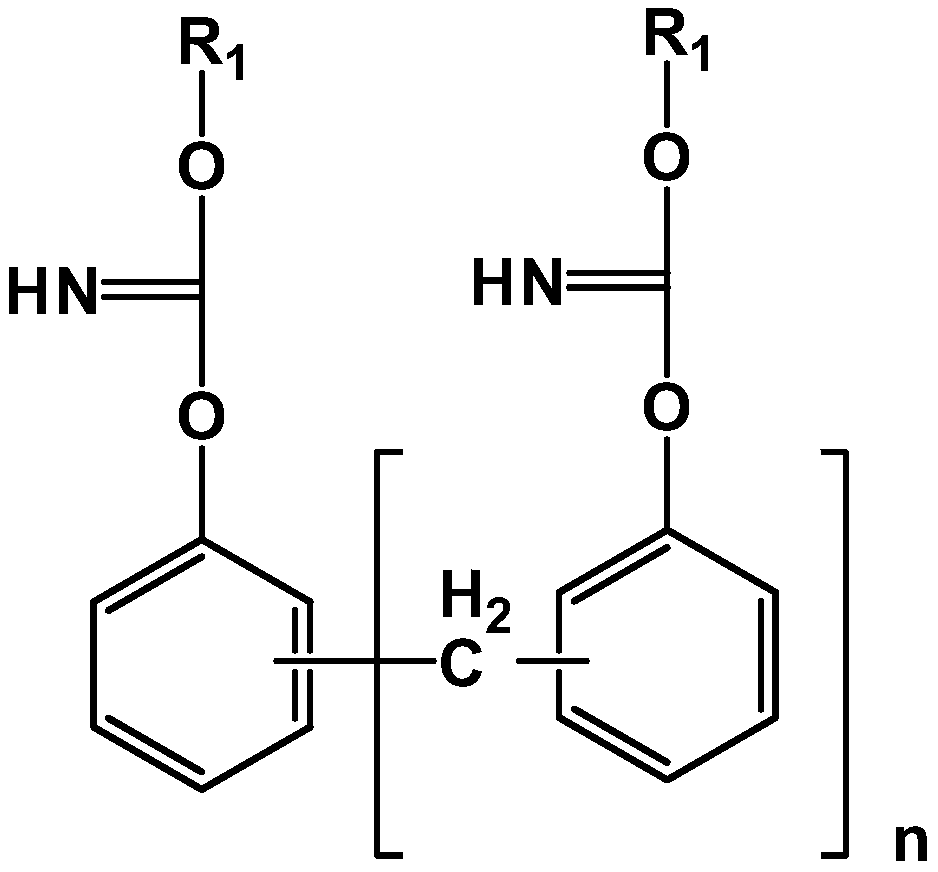

[0179] The cyanate group of Lonza's bisphenol cyanate compound (BA-230) and 1,2,3,6-tetrahydrophthalic acid (4-cyclohexene-1,2-dicarboxylic acid ) reacted at a molar ratio of 1:1 to prepare the iminocarbonate-based compound 1 as an acid-modified oligomer.

[0180] The acid value of the prepared iminocarbonate compound 1 was 145 mgKOH / g. At this time, the acid value of the prepared iminocarbonate-based compound 1 was measured by dissolving about 0.1 g of a sample in a 1:1 mixture of xylene and isopropanol, specifically by a method according to ASTM D1639 .

[0181] Using 10% by weight of the iminocarbonate-based compound 1, it was mixed with 15% by weight of ZAR-2000 and 8% by weight of CCR-1171H (Nippon Kayaku, Co., Ltd.), 5% by weight of DPHA (SK CYTEC CO., LTD.) as a photopolymerizable monomer, 2.5% by weight of TPO as a photoinitiator, 10% by weight of YDCN as a thermosetting adhesive- 500-8P (Nippon Kayaku, Co., Ltd.), 0.95% by weight of 2-PI as a thermosetting binder c...

Embodiment 2

[0185] A dry film and a printed circuit board were prepared in the same manner as in Example 1, except that 15% by weight of the iminocarbonate-based compound 1 was used and the content of the iminocarbonate-based compound Increasing the amount of solvent used increases.

Embodiment 3

[0187] A dry film and a printed circuit board were prepared in the same manner as in Example 1, except that: as shown in Table 1 below, 25% by weight of the CCR-117H was used, and as the photopolymerizable monomer 5% by weight of TMPA (SKCYTEC CO., LTD.) was used, and 8% by weight of YDCN-500-8P (Nippon Kayaku, Co., Ltd.) was used as the thermosetting adhesive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com