Method for determining real-time higher and lower calorific values of fuel gas in gas turbine power plant

A high-low level, electromechanical power plant technology, applied in the field of power engineering, can solve the problems of lack of accuracy of basic data, inability to reflect real-time fluctuations of gas parameters in real time, and affect power plants, etc., to achieve the effect of improving the level of refined management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

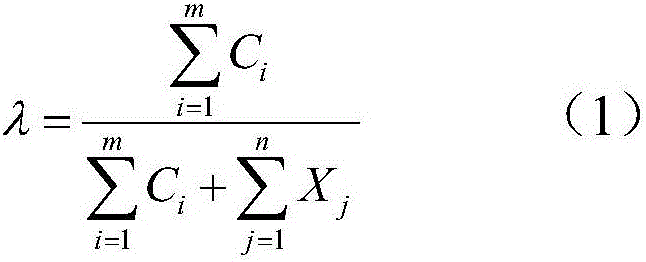

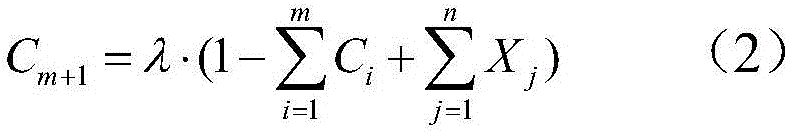

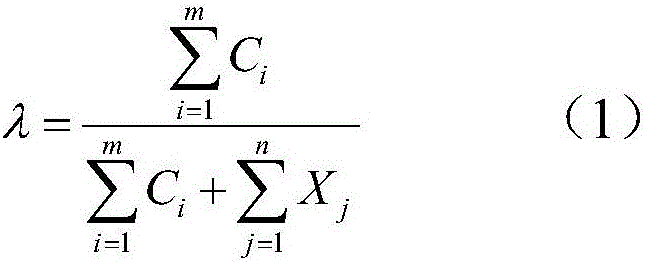

[0021] The present invention comprises the following steps:

[0022] 1) Calculate the real-time composition of combustible gas in the gas turbine

[0023] Based on the thermal power plant plant-level monitoring information (SIS system for short) platform, real-time collection of gas composition parameters, including non-combustible gas composition CO 2 Mole fractionX 1 , N in gas 2 Mole fractionX 2 ,..., other non-combustible gas mole fraction X n A total of n parameters, as well as the combustible gas content in the gas obtained in real time, including the methane mole fraction C 1 , ethane mole fraction C 2 , propane mole fraction C 3 ,..., other combustible gas mole fraction C m Wait for m parameters.

[0024] If the combustible gas composition and the mole fraction of the corresponding components are measured in real time in the power plant, and Then the real-time combustible composition of the gas is determined.

[0025] 2) Determine the high calorific value of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com