An installation structure for electric vehicle charging socket cover

A charging socket and installation structure technology, applied in electric vehicle charging technology, electric vehicles, charging stations, etc., can solve problems such as unsightly appearance, large space occupation, poor sealing performance, etc., and achieve simple operation process, small space occupation, and sealing good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

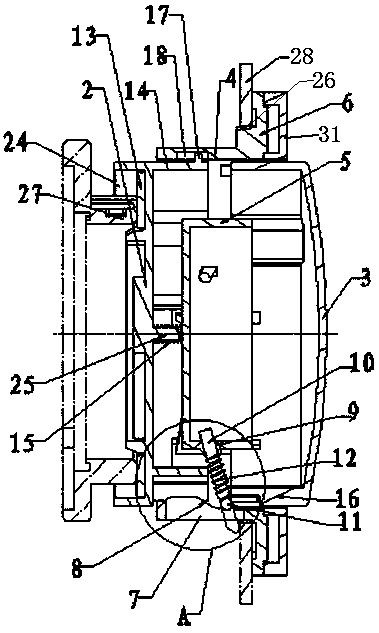

[0024] In order to clearly illustrate the technical features of this solution, the specific implementation of the present invention will be further described below according to the accompanying drawings.

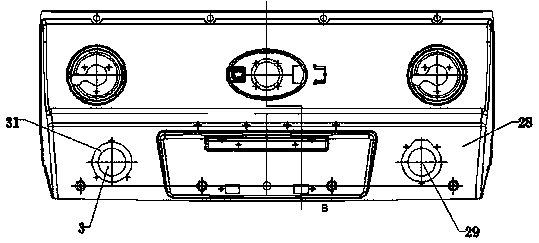

[0025] As shown in the figure, an installation structure of a charging socket cover for an electric vehicle includes a charging socket cover and a trunk cover 28, and the charging socket cover includes a locking cover 1, a sealing cover 2, an unlocking cover 3 and a trunk cover 28, The materials of the locking cover 1, the sealing cover 2 and the unlocking cover 3 are ABS plastics.

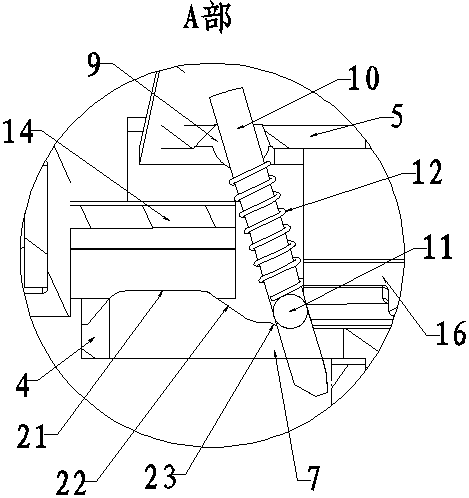

[0026] The locking cover 1 includes an outer sleeve 4, an inner sleeve 5 and a flange 6, the outer sleeve 4 is coaxially sleeved outside the inner sleeve 5, the flange 6 is fixed on the outer end of the outer sleeve 4, and the flange The outer end face of 6 is provided with annular decorative cover 31; Outer sleeve 4 walls are evenly distributed with three long holes 7, the length direction of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com