Power driver

A technology for electrical appliances and driving circuit boards, which is used in electrical components, AC motor control, estimation/correction of motor parameters, etc. The effect of avoiding voltage fluctuation and reducing loop loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

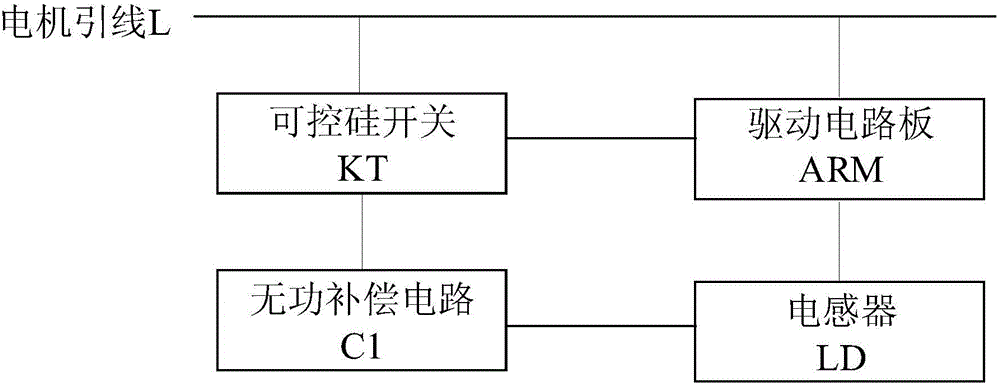

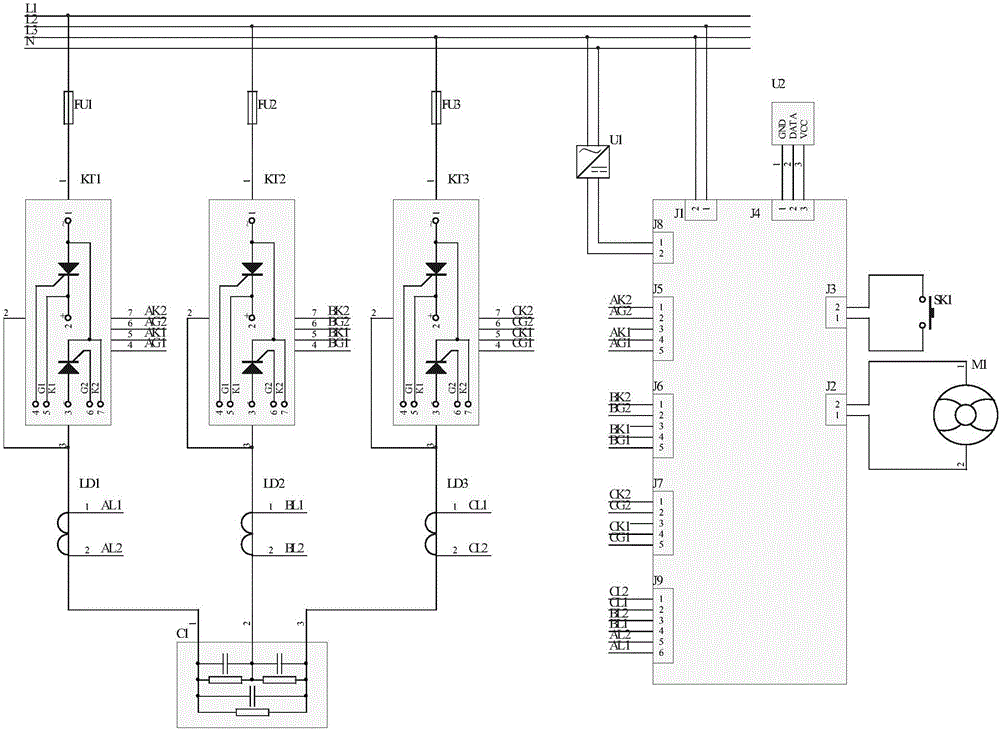

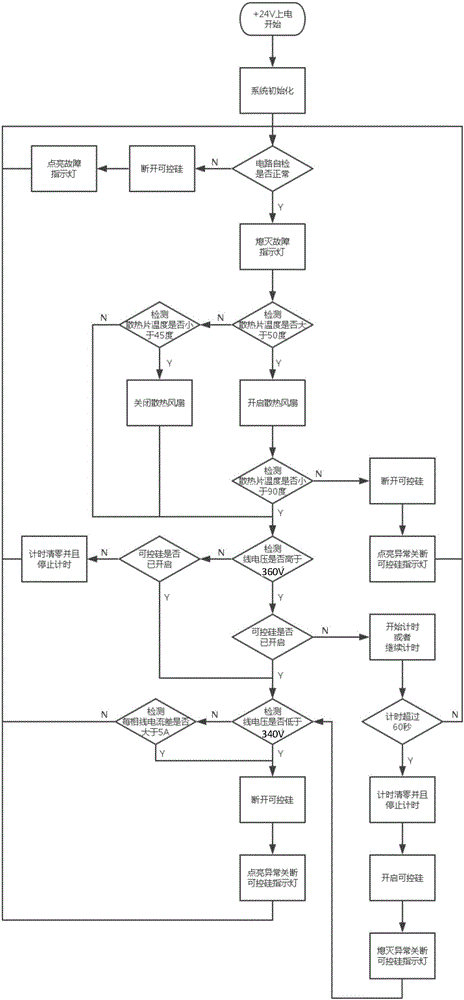

[0035] Specific implementation mode one: the driving device of this implementation mode is as follows figure 2 As shown, where L1, L2, L3, and N are the four lead wires of the motor. The power input terminal J8 of the drive circuit board is connected to the lead wires L3 and L2 of the motor through the switching power supply U1, the power detection terminal J1 detects the voltage, the timing terminal J4 is connected to the timing chip U2, the power reset terminal J3 is connected to the reset button SK1, and the fan is controlled. Terminal J2 is connected with fan motor M1. The drive circuit board also has A-phase thyristor control terminal J5, B-phase thyristor control terminal J6, and C-phase thyristor control terminal J7, and their pins are connected to A-phase thyristor switch KT1 as shown in the figure. , the corresponding pins of the B-phase thyristor switch KT2 and the C-phase thyristor switch KT3. One end of the three thyristor switches KT1, KT2, KT3 are respectively...

specific Embodiment approach 2

[0039] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the driving circuit board also includes a differential amplifier, and the input end of the differential amplifier is the current transformer end, which is used to amplify the detected current for easy detection. The circuit diagram of the differential amplifier is shown in Figure 5 shown.

[0040] Other components and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0041] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the drive circuit board also includes a reset terminal, which is connected to a reset button. When the drive circuit board fails, the reset operation can be performed through the reset button.

[0042] Other components and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com