Novel speed regulating apparatus for 3 phase high voltage switch reluctance motor

A high-power switching, reluctance motor technology, applied in the direction of speed/torque control of a single motor, can solve the problems of high insulation level requirements of power units, large number of three-phase transformer secondary groups, signal transmission and testing difficulties, etc. Achieve the effect of low insulation requirements, simple and convenient debugging, and power reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

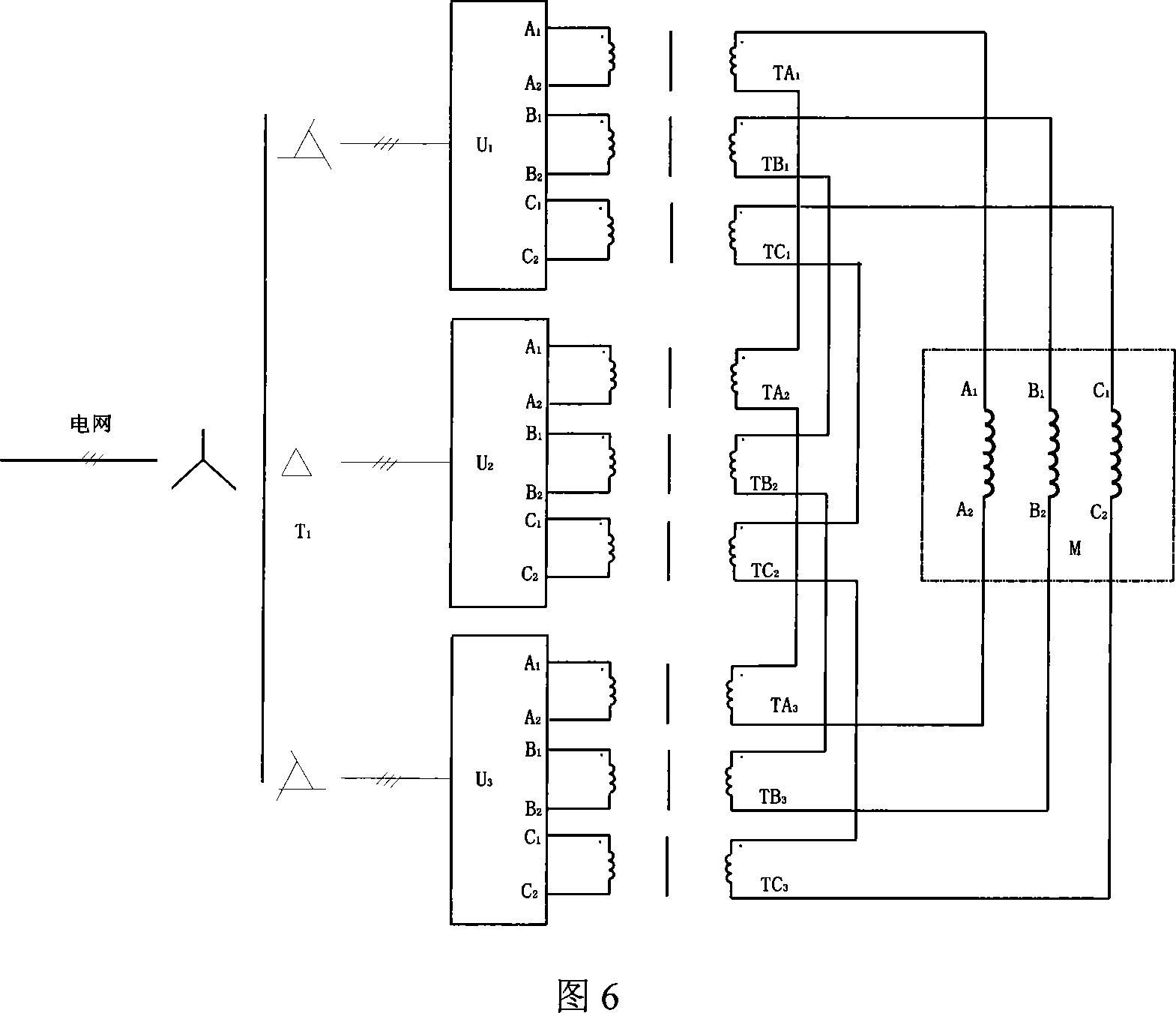

[0027] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

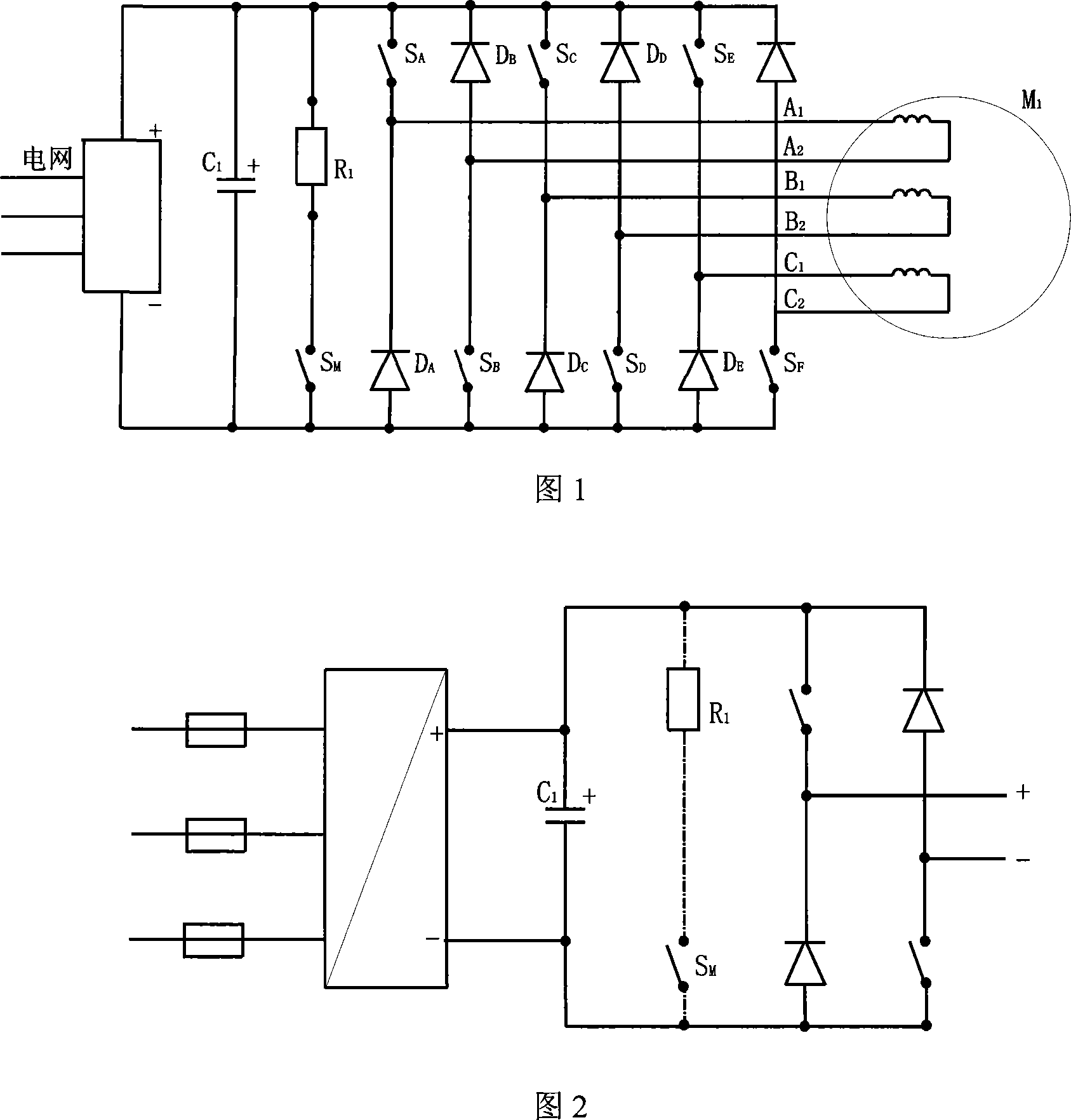

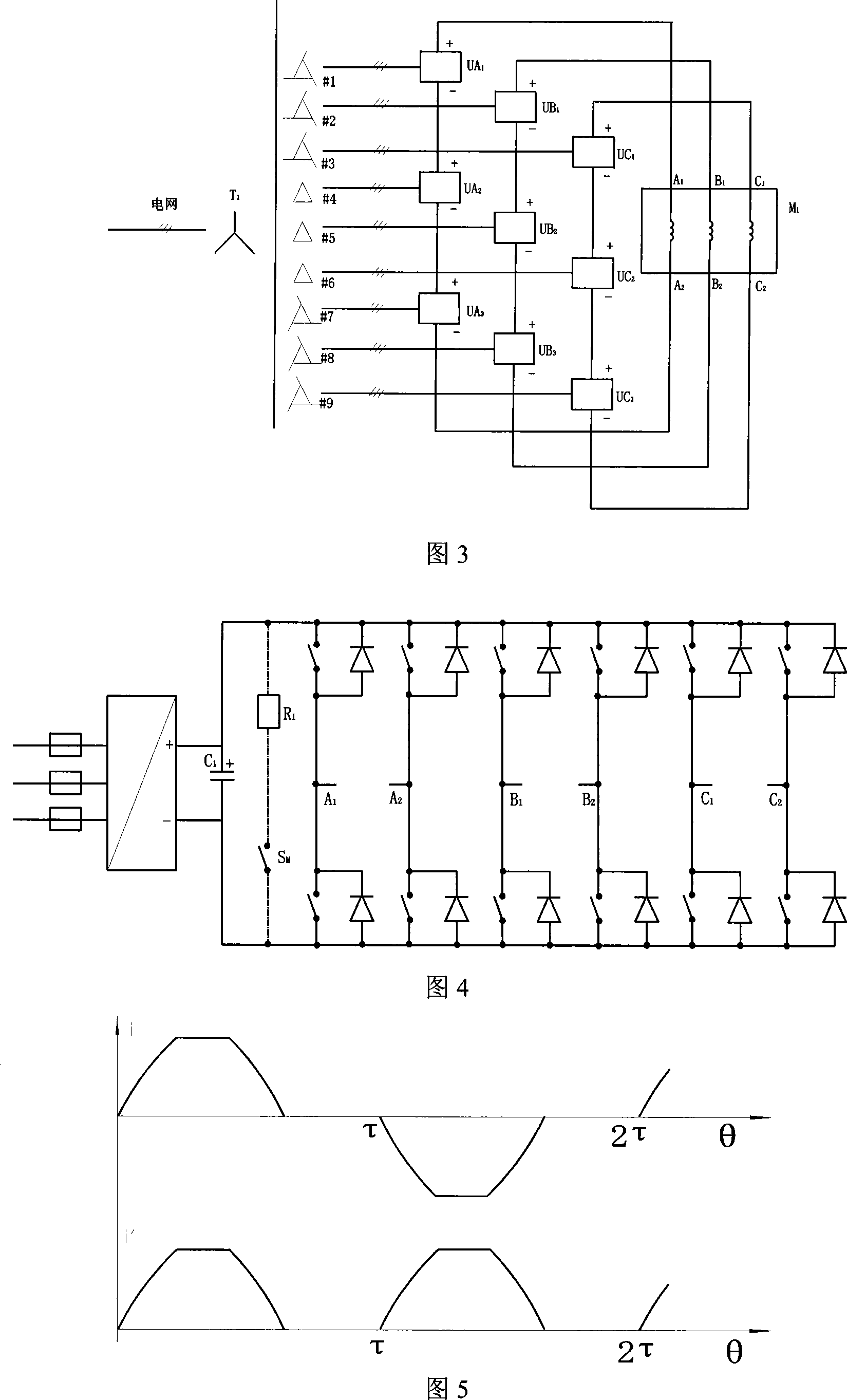

[0028] Fig. 4 shows the circuit diagram of the common type power unit of the present invention. The three-phase bridge rectification adopts capacitor filtering, and its three-phase input is connected with a fuse for protection, and sometimes it can be used as an isolating switch. The power inverter circuit has a total of six push-pull bridge arms, which constitute three independent single-phase full-bridge inverter circuits. As the two pairs of power switches on the diagonal are turned on in turn on average, the output drive current is positive and negative alternately. . The dotted line shows the voltage-limiting discharge circuit, which should be set when necessary.

[0029] In the power unit of the present invention, the power inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com