Propylene-based compositions of enhanced appearance and flowability

A composition, technology of propylene copolymers, applied in the field of propylene-based compositions, capable of solving problems such as not teaching or achieving the properties required for gel counting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0093] Still other embodiments of the present invention include methods of making impact copolymer polypropylene (ICP) compositions, such as any of the various embodiments of the ICP compositions described herein. According to certain embodiments, the process comprises: polymerizing propylene in the presence of a Ziegler-Natta catalyst in a first stage comprising at least one bulk or gas phase polymerization reactor or a combination thereof to produce a polypropylene-based matrix, For example, a matrix having a melt flow rate (MFR) greater than 125 g / 10 min; degassing and then transferring the polypropylene-based matrix phase from the first stage to a second stage comprising at least one gas phase reactor; and in the second stage polymerizes an ethylene propylene rubber (EPR) phase in the presence of a polypropylene-based matrix to produce an EPR phase dispersed in a polypropylene-based matrix to produce an impact-resistant polypropylene copolymer composition, wherein the EPR p...

Embodiment

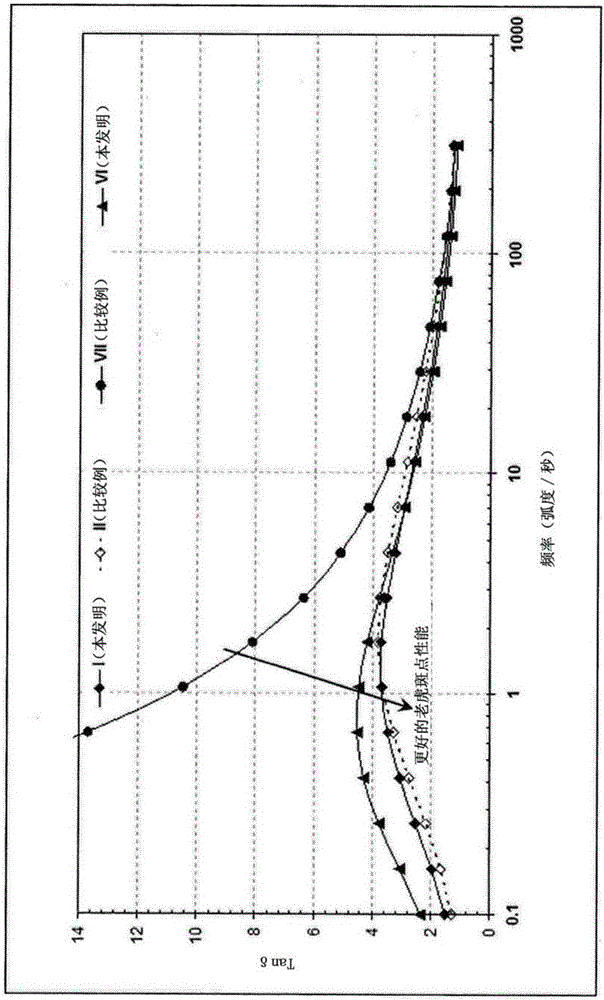

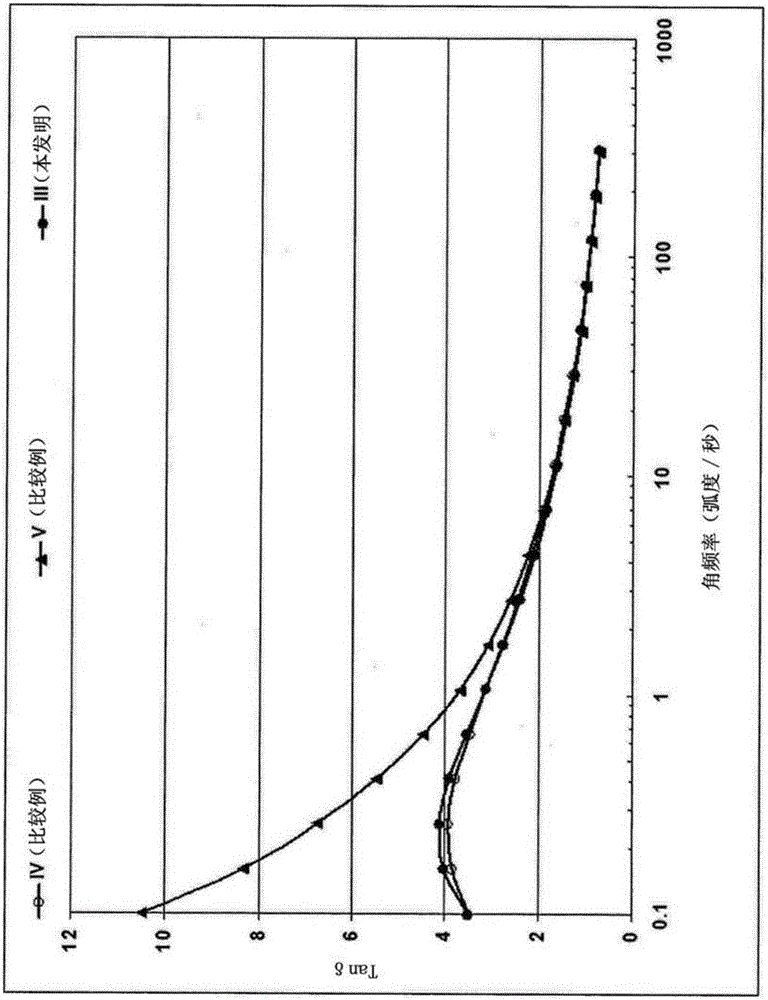

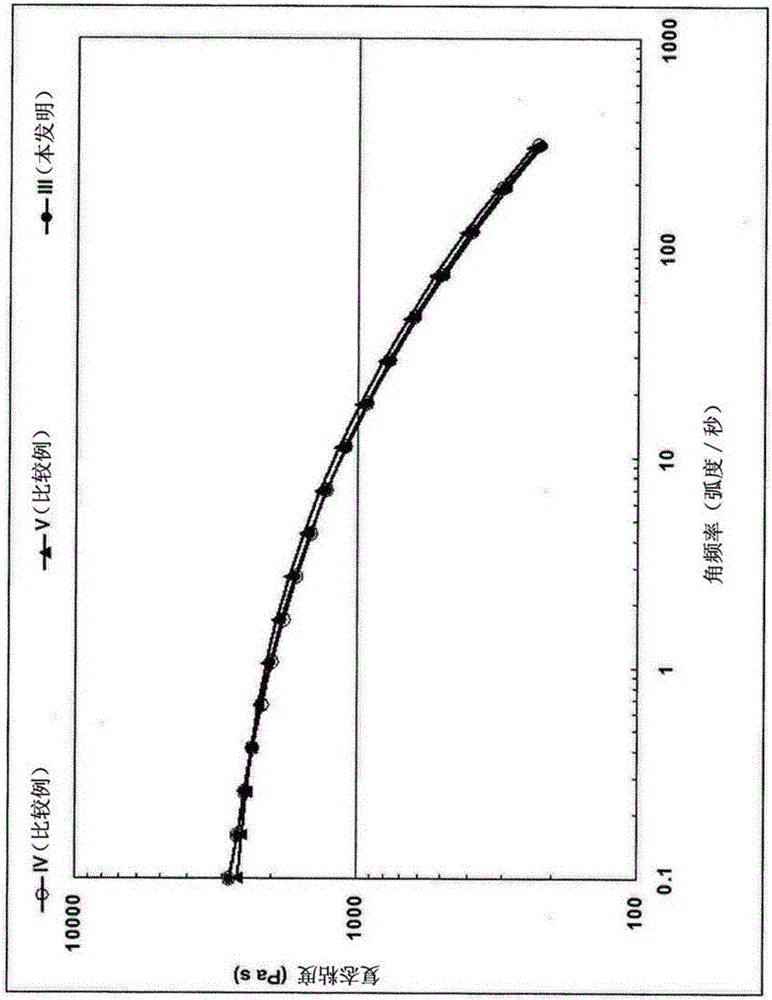

[0101] The invention will now be described in the following non-limiting examples, as summarized in the tables and figures below. Tables 4-7 below and Figure 1-3 Examples are included to demonstrate the invention. Some observations of the disclosed embodiments include:

[0102]Table 4 shows that for I.V. ratios > 4 between the EPR phase and the propylene-based matrix, the macrogel counts are surprisingly low ("excellent" gel performance), while the tiger spot performance is simultaneously excellent (at 0.1 rad / s 180℃, tanδ<5). As mentioned earlier, the I.V. of the EPR phase is defined in the present invention as the I.V. of the xylene soluble fraction precipitated from acetone. It has been experimentally confirmed that the I.V. of the propylene-based (matrix) phase is here approximately equal to the I.V. of the XIS fraction of the composition. At a given composition MFR, tan δ at low frequency (at 0.1 rad / s, 180°C) reflects the combination of various molecular features o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com