Method for the heat treatment of steel reinforcement element for tyres

A technology for reinforcing elements and tires, applied in the field of steel reinforcing elements, can solve problems such as cumbersome control, and achieve the effects of eliminating turbulence, easy control, and eliminating surface defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

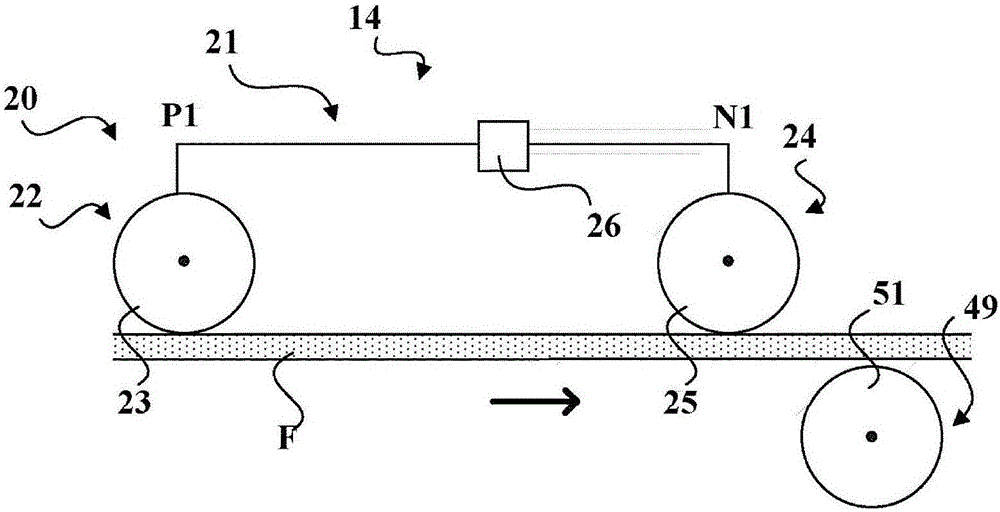

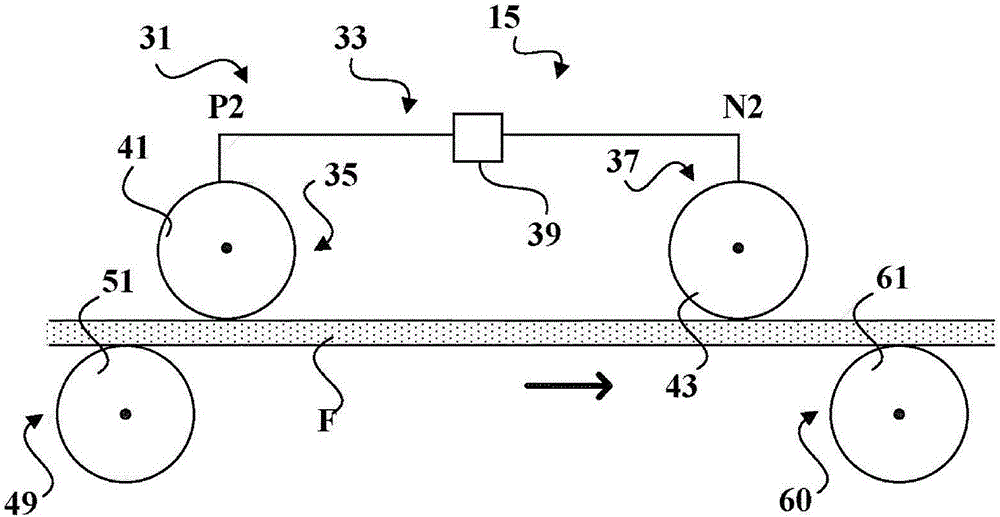

[0087] Example of a thermal treatment facility for carrying out the method according to the invention

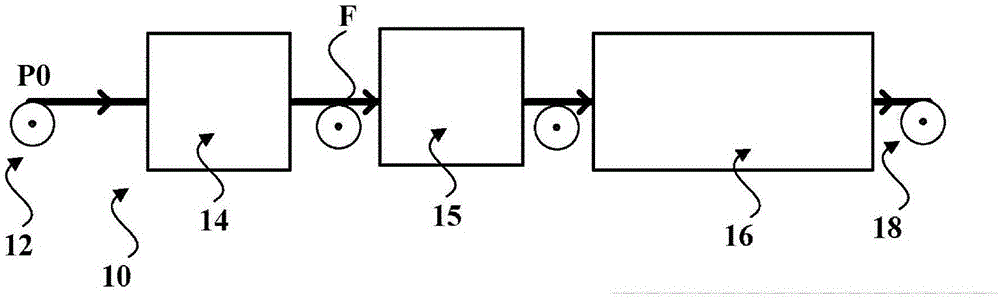

[0088] figure 1 Represented is a first embodiment of a plant for the thermal treatment of reinforcing elements of tyres, denoted by reference numeral 10 .

[0089] The processing facility 10 is capable of processing steel reinforcing elements F, here steel wires. The steel wire F has a diameter of 0.5 to 5.5 mm, preferably 0.7 to 3 mm, more preferably 1 to 2.5 mm.

[0090] In the direction of travel of the elements F in the installation 10, from upstream to downstream, the installation 10 comprises upstream means 12 for storing the elements F, means 14 for heating the elements F, means 15 for maintaining the temperature of the elements F, means for A facility 16 for cooling the elements F and a downstream device 18 for storing the heat-treated elements F.

[0091] The upstream storage device 12 and the downstream storage device 18 each respectively comprise a reel for sto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com