A kind of air distribution plate and reactor thereof

A technology of airflow distribution plate and distribution plate, which is applied in the direction of chemical instruments and methods, chemical/physical processes, etc., can solve the imbalance of circumferential flow state and axial flow state, cannot form a three-dimensional bed overall circulation, and the force of a circular plate is stronger than that of a shell. Body difference and other issues, to achieve the effect of no dead zone, safe and scientific space layout, and long production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

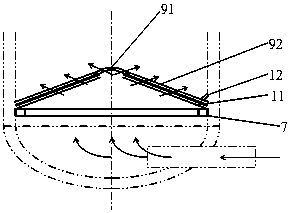

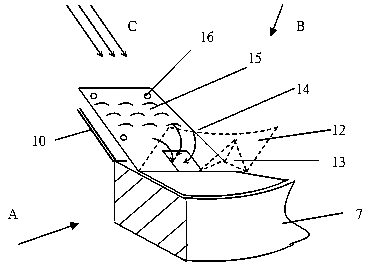

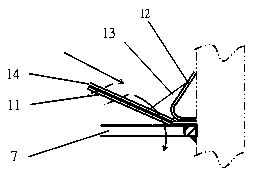

[0041] One of the specific embodiments of an air distribution plate of the present application, refer to figure 1 As shown, the structure is improved and formed by a flat air distribution plate. The innovation of the present application is that the air distribution plate includes a convex structure 91 protruding upward along the central axis of the air distribution plate and The peripheral edge of the structure 91 extends downward to the distribution plate body structure 92 of the inner wall of the cylinder 1 of the reactor. The innovative air distribution plate and the lower head of this application form a mouth-to-mouth enclosed large space relationship, which eliminates the original funnel-shaped distribution plate and goes deep into the lower head to form an overlapping set of narrow gap relationship structure, which improves the view from the bottom of the reactor After the incoming process gas enters the large space, the flow rate is reduced, the pressure is equalized, and...

Embodiment 2

[0052] The second specific implementation manner of an air distribution plate of the present application. The main technical solution of this embodiment is the same as that of Embodiment 1. For the unexplained features in this embodiment, the explanation in Embodiment 1 is adopted and will not be omitted here. Go ahead. The difference between this embodiment and embodiment 1 is that reference Figure 7 The gas flow distribution plate in the reactor structure is shown, wherein the distribution plate body structure 92 is a convex hyperboloid structure.

Embodiment 3

[0054] The third specific implementation manner of an air distribution plate of the present application. The main technical solution of this embodiment is the same as that of Embodiment 1. For the features that are not explained in this embodiment, the explanation in Embodiment 1 is adopted and will not be omitted here. Go ahead. The difference between this embodiment and the first embodiment is that the distribution plate body structure 92 is a concave hyperboloid structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com