Feeding mechanism for meat grinder

A technology of feeding mechanism and meat grinder, which is applied in the direction of grain processing, etc., can solve the problems of minced meat pollution, pollution of machine parts, etc., and achieve the effect of avoiding black powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

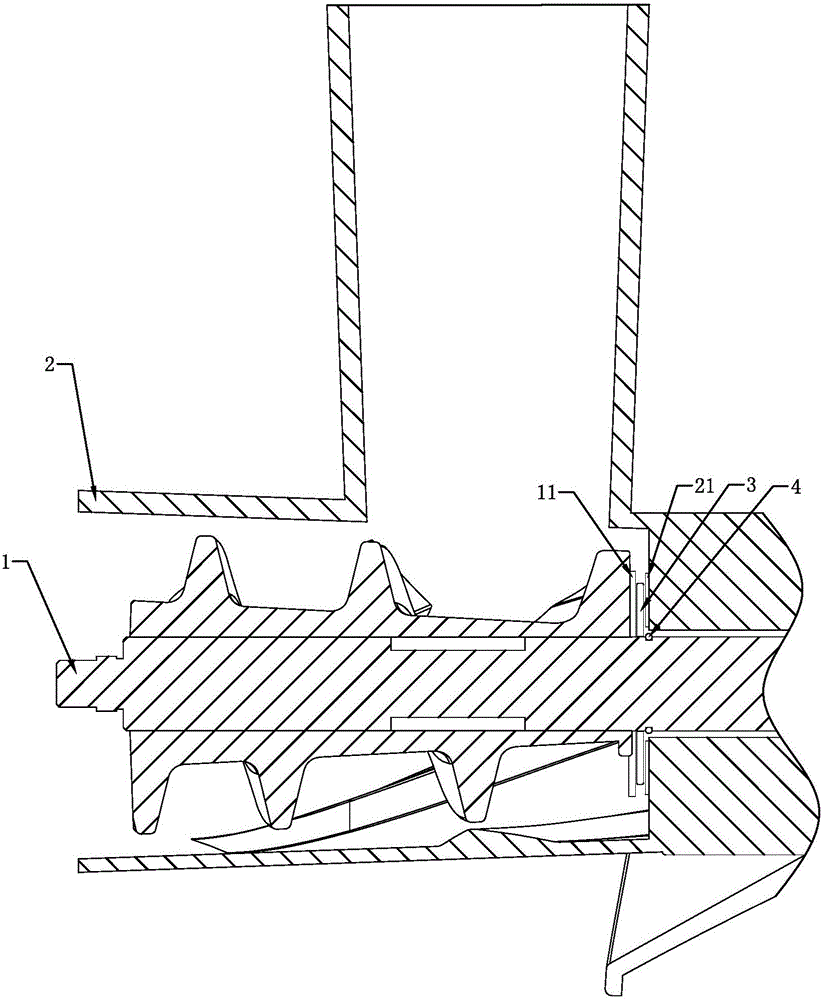

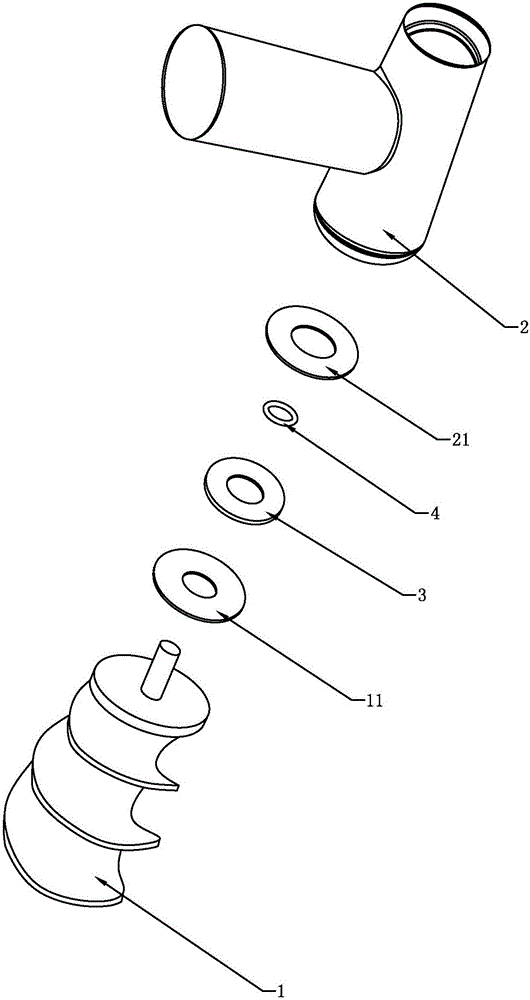

[0017] refer to Figure 1 to Figure 2 , a meat grinder feeding mechanism of the present invention, comprising a worm 1 and a twisting cylinder 2, the helical tooth tail of the worm 1 is fixedly provided with a gasket one 11, and the corresponding position of the inner wall of the twisting cylinder 2 is fixedly provided with a gasket two 21, preferably Yes, washer one 11 and washer two 21 are fastened with interference fit by die-casting or screws or riveting or extrusion, and are made of stainless steel, with a smooth surface and no secondary processing.

[0018] The gap between the washer one 11 and the washer two 21 is provided with a wear-resistant gasket 3. Preferably, a clip spring 4 is arranged between the wear-resistant gasket 3 and the inner wall of the winch tube 2 on the worm 1 for wear-resistant Gasket 3 is used to limit the position. The wear-resistant gasket 3 is made of wear-resistant metal materials, such as high manganese steel or high-phosphorus wear-resistant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com