Processing method of hot wind coupling biodrying for domestic waste

A technology of domestic waste and biological drying, applied in chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve problems such as affecting the growth of microorganisms, reducing degradable substances, reducing treatment efficiency, etc., and achieving less heat loss. , The effect of promoting moisture removal and heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

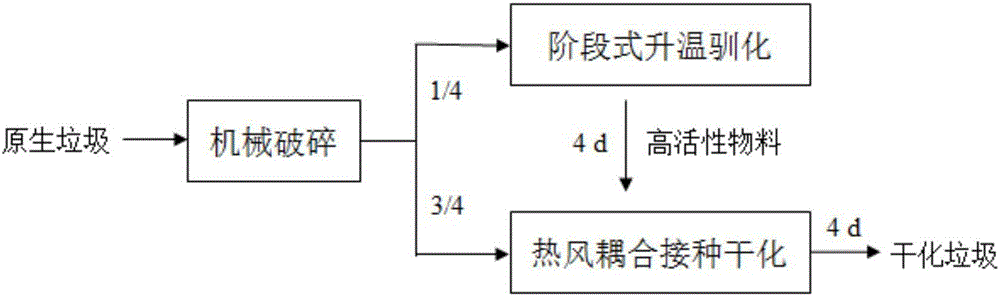

[0018] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

[0019] This implementation case is used for domestication of materials and inoculation drying reaction respectively to realize continuous treatment of domestic waste. The initial moisture content of domestic waste is 63%, and the proportions of each component are: kitchen waste 62%, plastic 17%, paper 6%, wood 5%, and other (inorganic substances such as glass and ash) 10%. Household waste is first processed through bag breaking, and large debris and metals are removed by sorting, and then undergoes secondary crushing. After crushing, the particle size of domestic waste is reduced to 5-10cm, and it is transported into the biological drying reactor through the conveyor belt. Double helix shaft stirring realizes domestic garbage turning and mixing. The reactor is equipped with a 9-19 high-pressure centrifugal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com